- HOME

- Sustainability

- Product Quality and Safety

CSR Activity Report (CSR Guideline Activity Reports)

Product Quality and Safety

Provide safe, highly reliable products by striving to enhance management systems for product quality assurance and safety, and disclose appropriate information.

Basic Approach

To live up to its “quality first” and “customer first” commitments, Toray Group has established policies on quality assurance and product safety, respectively, and an organizational framework to pursue both in an integrated manner.

Additionally, Toray Group supplies product safety information in accordance with the characteristics of the product or service. The Group is fundamentally committed to respecting the Eight Basic Consumer Rights and strives to secure the quality and safety of its products throughout its business activities.

The Medium-Term Management Program, Project AP-G 2025, directs Toray Group to achieve sound, sustainable growth along with innovation and resilience management, and this hinges on securing product safety and quality. Accordingly, the Group continued to address individual areas for improvement and execute product safety measures in fiscal 2023.

Related Policies

Toray Group Quality PolicyRevised June 2007

We give top priority to the product quality offered to our customers as well as to safety and to the environment in our corporate activities. We work on quality assurance with the stance of "Customer First."

- We make our best efforts to meet our customers' expectations with products and services of high satisfaction.

- We commit ourselves to abide by the "Quality First" principle, and to improve the quality and reliability of our products, in all our divisions, including sales, manufacturing and research and development.

- We meet quality requirements at the stage of design and development, and ensure and enhance these in the manufacturing process.

- We continuously strive to organize, maintain and improve our quality management system.

Product Safety Management Basic PolicyEstablished January 1992

- We shall place priority on the various measures required to ensure product safety.

- We shall conduct adequate safety evaluations prior to marketing a new product.

- For products already on the market, we shall take note of feedback from customers and the general public and always remain attentive to safety.

Related Information

See the following page for information on chemical management.

Structure

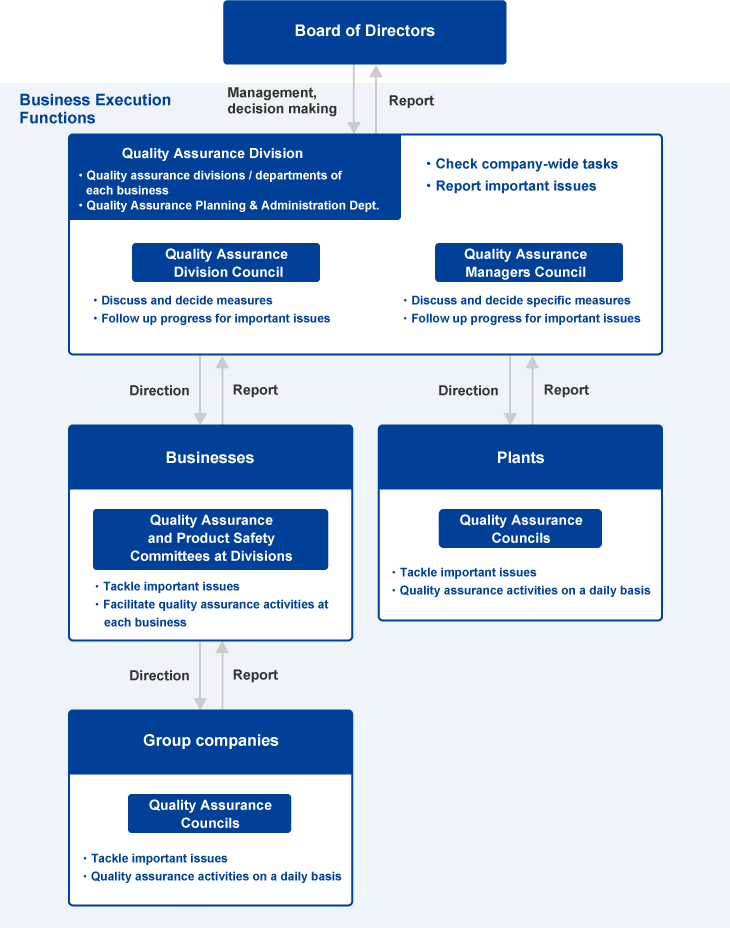

Framework for Quality Assurance

The quality assurance framework of Toray Industries, Inc. is shown in the diagram below. The Quality Assurance Division submits reports on its activities to the Board of Directors, and based on the board’s instructions, the Quality Assurance Planning & Administration Department devises appropriate measures. These are then communicated and promoted by the Quality Assurance Division Council, which meets monthly, and the Quality Assurance Managers Council, which meets twice a year. Quality assurance and product safety committees at divisions further examine the company-wide issues that have been identified by the Quality Assurance Division Council and Quality Assurance Managers Council, breaking them down into action items that are designated every year for implementation. Quality assurance, production, technology, and sales departments cooperate to tackle quality assurance issues and raise the level of activities.

business

・Quality Assurance Planning & Administration Dept.

Division Council

Managers Council

Product Safety

Committees at Divisions

Councils

Councils

Functions

・Report important issues

・Follow up progress for important issues

・Follow up progress for important issues

・Facilitate quality assurance activities at

each business

・Quality assurance activities on a daily

basis

・Quality assurance activities on a daily

basis

decision making

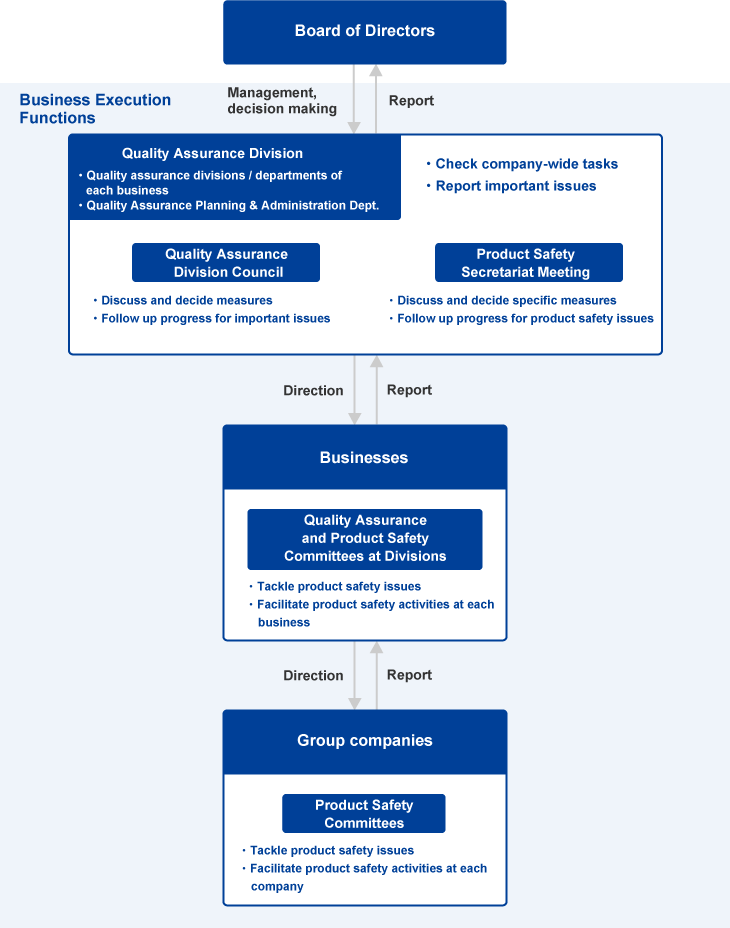

Framework for Product Safety

Toray Industries' product safety framework is shown in the diagram below. The Quality Assurance Division submits reports on its activities to the Board of Directors, and based on the board’s instructions, the Quality Assurance Planning & Administration Department devises appropriate measures. The Product Safety Secretariat Meeting then communicates and promotes the annual measures. Quality assurance and product safety committees at the divisions further examine the group-wide tasks that have been identified by the Product Safety Secretariat Meeting, breaking them down into action items that are designated every year for implementation. The action items are executed in cooperation with quality assurance, production, technology, and sales organizations at the departmental and divisional levels, to ensure thorough management of product safety and continue raising the level of management. Toray Group has been centrally tracking statistics on product accidents and the execution of product safety reviews since fiscal 2011.

business

・Quality Assurance Planning & Administration Dept.

Division Council

Secretariat Meeting

Product Safety

Committees at Divisions

Committees

Functions

・Report important issues

・Follow up progress for important issues

・Follow up progress for product safety

issues

・Facilitate product safety activities at each

business

・Facilitate product safety activities at each

company

decision making

Self-Inspections to Ensure Quality Assurance and Product Safety

Since fiscal 2016, Toray Group companies have been implementing self-inspections across a wide range of control categories using the C-MOS internal control monitoring online system, along with self-inspections for quality assurance and product safety. Any issues that are identified through the self-inspections are corrected to ensure that improvements are made. The self-inspections are conducted on a three-year cycle to ensure that the basic frameworks for quality assurance and product safety are in place. For the first three-year cycle, Toray Industries was inspected in fiscal 2016, followed by group companies in Japan in fiscal 2017, and group companies outside Japan in fiscal 2018.

For the second three-year cycle implemented in fiscal 2019, Toray Group assigned inspection items to verify the effectiveness of improvements, and self-inspections were conducted. For the third three-year cycle implemented in fiscal 2022, confirmation items for UL and other certifications were assigned, and in fiscal 2023, self-inspections were conducted by group companies in Japan.

CSR Roadmap 2025 Targets

CSR Roadmap goals

- Enhance the group-wide frameworks for quality control, quality assurance, and product safety management

- Achieve zero product accidents

Main Initiatives and Key Performance Indicators

KPI |

|

⑴ Ensure that quality assurance compliance education is being fully implemented |

4-❶ |

⑵ Enhance the auditing function to ensure improvement and continuity of Toray Group’s overall quality assurance framework, and conduct auditing to check its effectiveness |

4-❷ |

⑶ Expand the use of the quality-related data management system with fraud prevention features across the entire Group |

- |

⑷ Promote the construction of systems in each business to facilitate deliberation, approval, and management related to quality assurance activities |

- |

⑸ Aim for zero product accidents |

4-❸ |

| Key Performance Indicator (KPI) | Target | Fiscal 2023 Result | ||

|---|---|---|---|---|

| Fiscal 2023 | Fiscal 2024 | Fiscal 2025 | ||

| 100% | 100% | 100% | 100% | |

| 100% | 100% | 100% | 100% | |

| 0 | 0 | 0 | 11 | |

- Reporting Scope: Toray Group

- 1 An incident occurred involving air filter media sold by Toray. During processing of the material at a customer facility, a white powder was noticed and multiple line operators experienced skin irritation. However, their symptoms were mild and completely alleviated with over-the-counter ointments. While an investigation by experts did not establish a clear causal relationship between the white powder and the symptoms, Toray treated it as a product safety incident. Accordingly, the group company that manufactures the air filter media was given instructions intended to reduce any occurrence of the white powder during the customer’s process. After implementation of these measures, no further symptoms occurred.

Related Materiality for CSR

- Enhancing Product Quality and Safety

- * Click here for the Materiality View of CSR Roadmap 2025 (PDF:392.4KB).PDF

Looking to the Future

In fiscal 2024 and beyond, Toray Group will address individual issues related to improving quality assurance and product safety, while continuing to enhance its group-wide management systems for both quality assurance and product safety.

Click here for the main initiatives and KPIs for CSR Guideline No. 4 “Product Quality and Safety” during the CSR Roadmap 2025 period (fiscal 2023–2025).PDF

Fiscal 2023 CSR Activity Report

Click bellow on activity reports for fiscal 2023.