Realizing a Circular Economy

As a manufacturer of a wide range of materials, Toray Group has been promoting various recycling initiatives to ensure that the earth's resources are efficiently utilized.

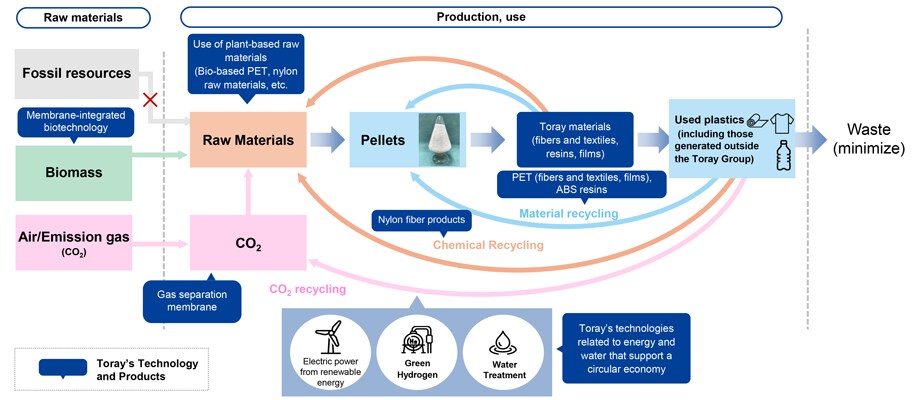

In the Toray Group Sustainability Vision, the Group outlines “a world where resources are sustainably managed,” as one of the perspectives of the world as envisioned in 2050. Conventional societies face a variety of problems, including the depletion of resources, marine pollution caused by large amounts of waste, and CO2 emissions. In order to solve these problems and realize a sustainable, circular economy that makes effective use of resources, the Group facilitates recycling of discarded plastic products and process remnants, switching to biomass for raw material, adopting renewable energy and hydrogen, and reusing water, across its various technologies.

In its Medium-Term Management Program, Project AP-G 2022, Toray Group identified helping to build a circular economy as a key issue. An initiative example in this area is material recycling1, which enables the reuse of discarded products and process remnants, such as fibers/textiles, resins, and films. In addition, chemical recycling2, which converts products and process waste that are not suitable for material recycling back into basic chemicals such as monomers and gases, is already implemented for nylon fiber products.

Toray Group is also working to develop materials that use biomass-derived resources instead of fossil resources, and membrane-integrated bioprocess technology, which efficiently produces these raw materials. Moreover, with an eye to the future, the Group is promoting research and development into carbon recycling, including ways to utilize CO2 as a resource. Toray technology is also used in the materials for the wind turbine blades and hydrogen production equipment that utilize renewable energy sources to generate electricity and hydrogen used in manufacturing processes, as well as in the water treatment membranes for the reuse of wastewater.

Under the Medium-Term Management Program, Project AP-G 2025, launched in fiscal 2023, Toray Group has set out helping to build a circular economy as an important objective. Accordingly, the Group aims to improve the value of its products and businesses by promoting further R&D.

Toray has identified the opportunities and risks associated with the transition to a circular economy as follows.

Opportunities

- Growth of materials business through use of biomass-derived materials

- Growth of materials business through use of recycled materials

- Growth of businesses that help reduce waste (waste reduction, and product durability)

Risks

- Increased cost of waste processing

- Contraction of the materials market due to a shift away from mass production and consumption

- Lost opportunities due to any delay in adapting to the circular economy

In order to reduce the risks and maximize the opportunities, the Group is promoting the use of biomass-derived and recycled materials as outlined below. In promoting these, Toray is also helping to create systems that can lay the foundation of a circular economy. These efforts include not only Toray Group's own activities, but also collaboration with recyclers (e.g. PET bottle recycling with Kyoei Industry Co., Ltd., and discarded fishing net recycling with Refineverse Group, Inc.), and collaboration with customers (e.g. fishing net-to-net recycling with Nitto Seimo Co., Ltd. and Maruha Nichiro Corporation, as well as technical demonstration of subcritical depolymerization of automobile parts with Honda Motor Co., Ltd.).

- 1 Material recycling is a process that regenerates pre-consumer or post-consumer materials into recycled materials through physical means. Examples include cutting, sorting, crushing, washing and decontamination (removal of dirt and foreign matter), and melting.

- 2 Chemical recycling is a process that chemically decomposes pre-consumer or post-consumer materials to recover useful chemical substances. Examples include decomposition, liquefaction, gasification, and depolymerization.

Toray Group's target percentage of raw materials sourced from biomass and other recycled is 20% to be achieved by fiscal 2030 for core polymers (polyester and nylon). The actual rate in fiscal 2024 was only a few percent, and to achieve the 2030 target the Group will continue to promote recycling and the switch to biomass for raw materials.

As part of its efforts to promote recycling and the use of bio-based materials, Toray Group has adopted the mass balance approach3. The following Toray companies and sites have obtained ISCC PLUS certification, an internationally recognized system to verify proper use of the mass balance approach by companies.

- Toray Industries, Inc. (Tokyo Head Office, Ehime Plant, Nagoya Plant, Tokai Plant, Okazaki Plant, Chiba Plant, Gifu Plant, Ishikawa Plant)

- Toray Celanese Co., Ltd.

- Toray International, Inc. (Tokyo Head Office, Osaka Head Office, Singapore)

- Toray Plastics (America), Inc. [Rhode Island, Virginia]

- Toray Composite Materials America, Inc. [Decatur, Spartanburg]

- Toray Films Europe S.A.S.

- Toray Carbon Fibers Europe S.A. [Abidos, Lacq]

- Delta-Preg S.p.A.

- Toray Advanced Materials Korea Inc. [Head Office, Gumi Plant 1, Gumi Plant 3]

- Toray Plastics (Malaysia) Sdn. Berhad

The ISCC PLUS certification system ensures appropriate management and traceability for production using biomass or recycled materials, based on the mass balance approach, as part of a global supply chain. Certified sites are able to allocate and use biomass or recycled materials according to the mass balance approach and produce and supply products with verifiable levels of sustainability.

Toray Industries is committed to following the latest ISCC regulations and declares its conformity to the ISCC PLUS requirements.

- 3 Mass Balance Approach: During the processing and distribution stages from raw material procurement to finished product delivery, materials with specific characteristics (e.g., biomass-derived raw materials) are often mixed with materials without those characteristics (e.g., petroleum-derived raw materials). The mass balance approach is a method for reliably allocating the characteristics of specific raw materials to a portion of the finished product based on the input amount of those raw materials.

The Group has also established new internal certification criteria in its Toray Group Certification Standards for Recycled and Biomass-based Products. These standards set out criteria defining which Toray products are eligible to be labeled a “recycled product” or a “biomass-based product,” allowing this to be clearly communicated to customers and markets. Verification and control of target products is carried out in accordance with these standards.

Recycling Activity PrinciplesEstablished in March 2004

- We shall design, produce, and sell products that reduce our impact on the environment.

- We shall purchase and use materials and products which will help reduce our impact on the environment.

- We shall disclose information related to recycling programs and recycled goods.

- We shall voluntarily cooperate with customers to recycle or otherwise appropriately dispose of our products.

Related Information

For more information on Toray Group waste reduction, chemical management, energy conservation, and climate change measures, please visit the website below.

Participation in Initiatives to Promote a Circular Economy

In cooperation with various external organizations, Toray Industries, Inc. is working to address challenges in achieving a circular economy. The main initiatives in which Toray Industries participates are as follows.

- Ministry of Economy, Trade and Industry: Circular Partners

- SusPla (Sustainable Plastics Initiative) (available only in Japanese)

- Textile Exchange

Biomass-derived materials business

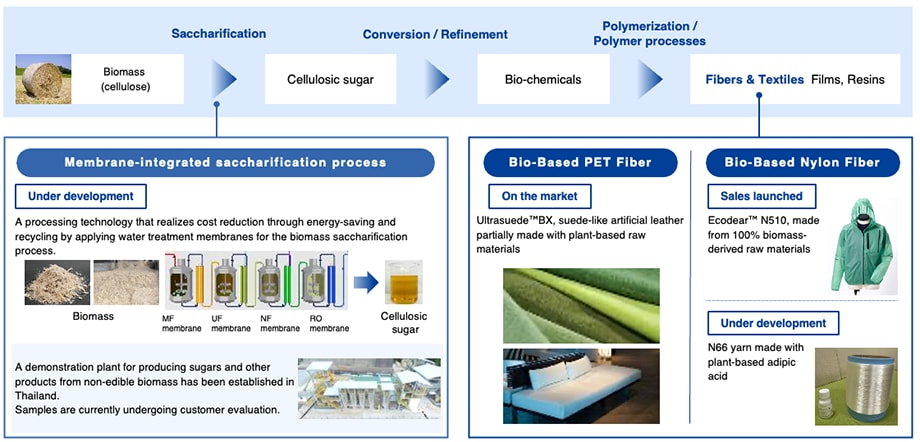

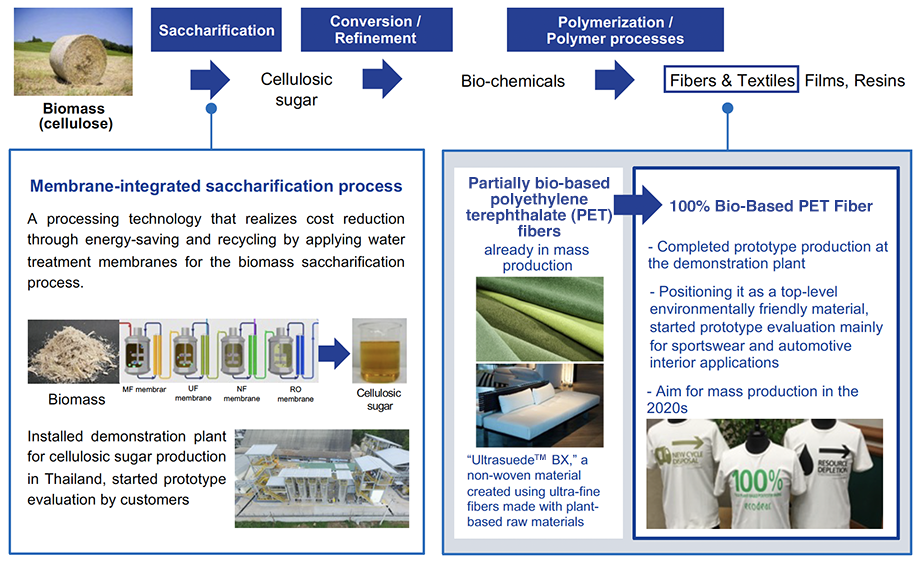

Toray Group is promoting initiatives related to biomass-derived raw materials under a unified brand, Ecodear™. It is developing these products using raw materials derived from biomass-derived resources rather than fossil resources. For example, Toray Group mass produces partially bio-based polyethylene terephthalate (PET) fibers that are made from plant-based ethylene glycol, derived from molasses byproducts. These fibers are also used to make Ultrasuede™PX and Ultrasuede™BX synthetic suede texture fabrics. Toray Group is proceeding with prototype sales of bio-based PET fiber, in which both of the main raw materials, ethylene glycol and terephthalic acid, are derived from biomass resources. The Group is also developing membrane-integrated bioprocesses for the in-house production of biomass-derived raw materials. In the field of nylon fibers, the Group has recently developed and launched Ecodear™N510, a nylon fiber made from 100% plant-based raw materials. As part of collaborative projects, this fiber has been utilized for the TANKER series of bags by Yoshida Co., Ltd. and in the STRINGS lineup of clothing from ISSEY MIYAKE Inc.

Membrane-Integrated Bioprocesses

Toray Group is developing a membrane-integrated bioprocess to enable biomass-derived raw materials to be manufactured with greater efficiency. This membrane-integrated bioprocess combines membrane separation technology and biotechnology to create new applications for water treatment membranes in processes such as saccharification, fermentation, and purification. The technology significantly improves the manufacturing of raw sugar from non-edible biomass and increases fermentation efficiency, thereby contributing to realizing materials made from biomass-derived raw materials. Toray Group is currently operating a technology demonstration project for a saccharification process that produces sugars from nonedible biomass. Toray Group will work to commercialize the technology, in order to build a supply chain that produces materials and chemicals from non-edible biomass.

In 2023, Toray Industries, Inc. and PTT Global Chemical Public Company Limited began jointly developing technology to produce muconic acid and bio-based adipic acid—raw materials for nylon 66—using sugars derived from non-edible biomass as feedstock. These sugars are manufactured at Cellulosic Biomass Technology Co., Ltd. (Thailand), in which Toray holds an 84% stake. This effort led to the world’s first successful pilot-scale production.

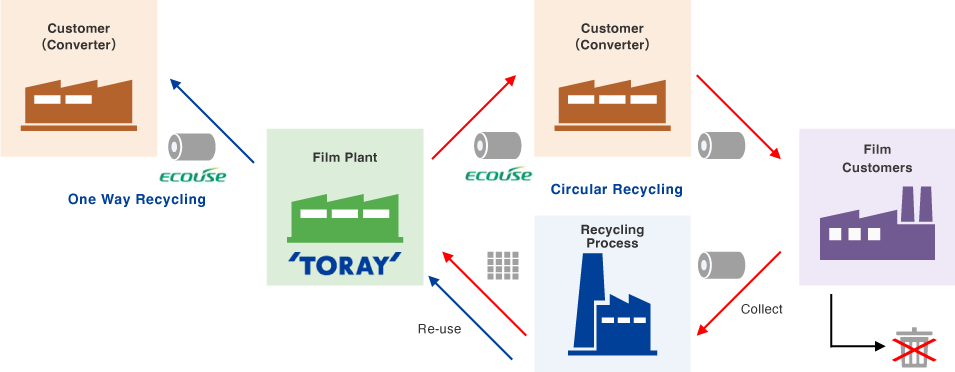

Promoting Recycling

Toray Group is promoting recycling initiatives across a wide range of business segments including fibers & textiles, plastics, and films. The Group works with fibers derived from recycled plastic (PET) bottles and production scrap ends, recycled resin made from scrap ends and used plastics, as well as films made by recovering and recycling films that have been used in customer processes.

In the fiber/textile segment, Toray Group uses discarded PET bottles as raw materials, along with filtering and cleaning technologies to remove foreign matter, making it possible to develop a wide variety of recycled products. In 2019, Toray Group introduced the &+™ (And plus) brand of recycled fibers that include Toray’s original traceability function. After rebranding in April 2023, the Group added recycled fiber products made using nylon recovered from discarded fishing nets to the &+™ brand.

In 2024, the Group analyzed the depolymerization reaction of Nylon 66 using subcritical water4 and, through its proprietary technology that suppresses side reactions, successfully recovered two types of monomers at high yield and efficiency, then repolymerized them to regenerate Nylon 66. This nylon is mainly used in automotive and industrial applications such as airbags, leaving open the possibility of expanding the range of applications in chemical recycling.

By utilizing waste fibers, resin, and film, the Group is promoting initiatives to create systems that recycle materials for various uses.

- 4 Subcritical water: Water in a high-temperature, high-pressure state just below its critical point (374°C, 22 MPa), possessing properties such as the ability to dissolve and hydrolyze organic compounds. This state differs from the characteristics of water at room temperature and regular atmospheric pressure.

Fiber and Textile Recycling

&+™ Recycled Fiber Brand

Previously, fibers derived from recycled PET bottles were limited in variety due to contaminants mixed into raw materials, which made it difficult to produce special cross-sections and fine fibers. In response, Toray Industries together with Kyoei Industry Co., Ltd. developed contaminant filtering technology and advanced plastic bottle cleaning techniques to stabilize the supply of high-quality raw materials. Combining these technologies with Toray’s fiber production technology, it is possible to achieve the same level of diversity in fabric applications as with fiber materials made directly from fossil resources. Moreover, Toray has commercialized its highly reliable polyester fiber under the &+™ brand by incorporating its proprietary traceability technology that can detect special additives premised in with plastic bottle-based raw materials. In January 2020, Toray Industries began full-scale sales of &+™ brand products. Going forward, the goal is to expand the scale of the brand by utilizing a diverse supply chain that includes textiles and sewn products, as well as fibers, and involves production sites around the world. The Group is also creating a unique recovery scheme for discarded fishing nets in collaboration with a recycling company and a fishing net manufacturer. The nylon in the recovered nets will be used for a newly released recycled nylon fiber material sold under the &+™ brand. Through the production and sale of high-value-added recycled nylon fiber based on Toray’s chemical recycling technology, the Group aims to raise awareness of the need to help recover discarded fishing nets and is working to further promote the activity.

In addition, Toray Industries is also promoting industry–academia collaboration projects utilizing &+™. In its initiative with Otsuma Women’s University, Toray partnered with the university student brand “m_r tokyo" to jointly develop an environmentally conscious parasol with heat-shielding, light-shielding, and UV-protection functions. In its initiative with Bunka Fashion College, Toray carried out a fabric printing and design project for yukata (summer kimonos) using &+™, aimed at fostering the next generation of designers.

The Group also intends to expand its recycled fiber material lineup to enable product planning that will further satisfy the needs of consumers.

Promoting Recycling with UNIQLO Co., Ltd.

Together with UNIQLO Co., Ltd., Toray Industries has been promoting new initiatives for sustainable products. Since 2020, Toray has jointly developed fibers derived from PET bottles, supplying them for use in some of UNIQLO’s quick-drying wear DRY-EX brand polo shirts and for its functional innerwear AIRism.

In addition, UNIQLO stores are collecting used down items from customers to recycle the feathers. Conventionally, the stuffing in duvets and other objects incorporating down is manually removed. Such processes are arduous with Ultra Light Down items because of their thin outer fabric and complex construction. By developing special extraction machinery, Toray Industries has fully automated cutting, stirring and separating, and recovery, for 50-fold the process capacity of manual processes, thus greatly alleviating workloads. Toray and UNIQLO are jointly developing new recycling-based down products from recycled feathers.

Resin Recycling

Toray Group is developing sustainable resin materials using recycled and biomass-derived raw materials.

In the area of resin recycling, the Group is developing and distributing recycled resins based on a proprietary formulation design using material and chemical recycling (depolymerization chemical recycling), which breaks down polymers into monomer raw materials before re-polymerizing them.

Going forward, Toray will actively work to recycle resin using post-consumer material for recycling, thereby promoting sustainable resource utilization.

Furthermore, Ecouse™, a group-wide unified brand for recycled materials and products, will be expanded to include resins, and the development of the Ecouse™ series of environmentally friendly resin materials will be accelerated.

- Recycled Nylon 6 Resin “Ecouse” AMILAN™

Toray Industries and Honda R&D Co., Ltd. have begun a joint development project for chemical recycling of automotive nylon 6 resin. This project focuses on a chemical recycling technology that uses subcritical water to depolymerize glass fiber-reinforced nylon 6 resin parts recovered from scrap vehicles, thereby producing the raw monomer caprolactam. Toray and Honda have developed this technology to leverage the high permeability, dissolving power, and hydrolytic capabilities of subcritical water, and have succeeded in using it to depolymerize nylon 6 resin. As a form of high-temperature, high-pressure water, subcritical water can depolymerize nylon 6 without the use of catalysts. There are no additive effects, and it generates a high yield of raw monomer in less than half an hour. After the raw monomer is separated and purified for repolymerization, the resulting recycled nylon 6 has physical properties equivalent to those of virgin material. - Recycled nylon 66 Resin “Ecouse” AMILAN™

Toray has developed a recycled nylon 66 resin compound that is made by removing silicone from airbag fabric scrap cuttings, and then washing the remaining material. With Toray’s proprietary additive compounding technology, residual silicone resin is prevented from migrating to the surface of molded products, and mold adhesion is also significantly reduced. Accordingly, the flowability and mechanical properties of recycled nylon 66 “Ecouse” AMILAN™ are on par with injection molding grades derived from virgin raw materials. - Recycled PBT (polybutylene terephthalate) resin “Ecouse” TORAYCON™

Toray has launched a recycled PBT resin, “Ecouse” TORAYCON™, as a chemically recycled resin with physical properties comparable to virgin materials. - Recycled PPS (polyphenylene sulfide) resin “Ecouse” TORELINA™

Toray has developed a material recycling technology for glass fiber reinforced PPS resin.

In the area of biomass-derived raw material use, Toray has established a supply system for bio-based ABS (acrylonitrile butadiene styrene) resin, bio-based PPS resin, and chemically recycled PPS resin (ISCC PLUS certified) using the mass balance approach.

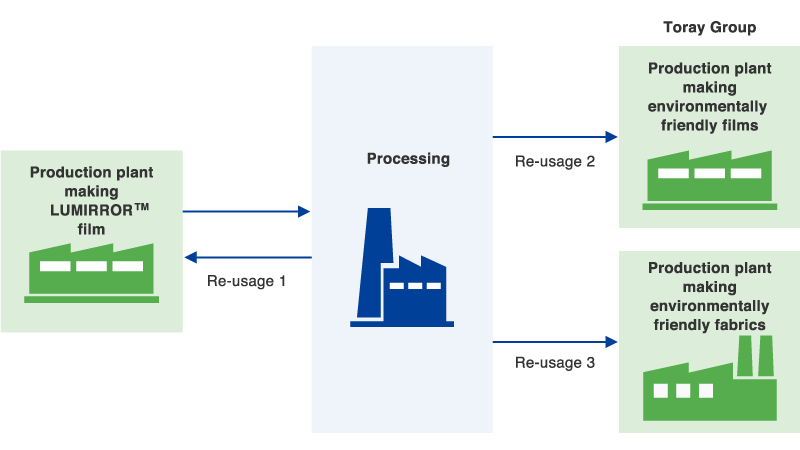

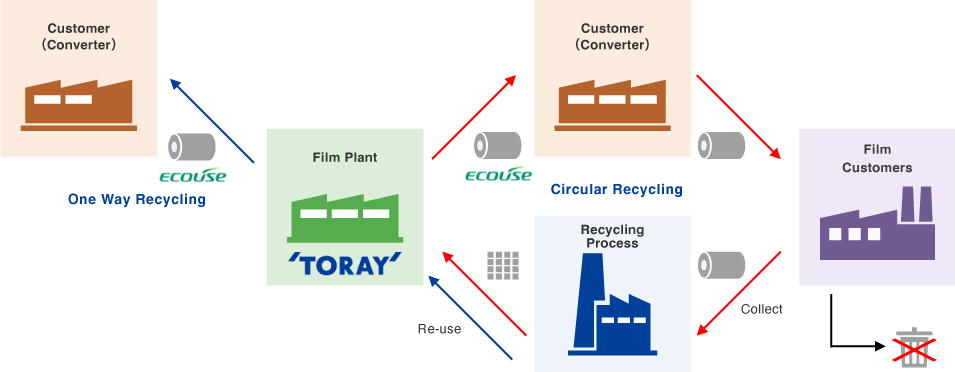

Film Recycling

Toray Industries is promoting production activities that use resources carefully. PET plastic generated as waste in PET film LUMIRROR™ manufacturing and other processes are collected and re-pelletized for use in making textiles and resin products and film. In addition, the Company operates a system for collecting used PET film from customer manufacturing processes, and then recycling it as raw material for film.

Reusing waste PET film from customer manufacturing processes

Toray Industries has established a recycling system to collect waste PET films from electronic component applications and recover them for use in the production of PET films, launching the Ecouse™ series. This contributes to creating a world where resources are managed sustainably, as outlined in the Toray Group Sustainability Vision. The company combined mechanical recycling process technologies, which remove coating materials and resins from film surfaces, with foreign matter removal techniques for each manufacturing process to enable reuse of the recovered materials in films without impairing mechanical characteristics or reliability. These PET films have reduced the amount of fossil-based resin used as a raw material and can therefore lower CO2 emissions by up to 50% compared to conventional films. The company will continue to utilize this system to help build a circular economy.

Carbon Fiber Recycling

TORAYCA™ carbon fiber, with its excellent mechanical properties, provides products that are lighter in weight and have longer lives. Carbon fiber also contributes to the reduction of CO2 emissions throughout the product’s lifecycle, helping to solve global environmental issues. In particular, the use of TORAYCA™ in applications such as large wind turbines, aircraft, and hydrogen tanks significantly reduces CO2 emissions during their operation. As demand grows, market expectations for the development of carbon fiber recycling technologies are also on the rise.

The successful development of recycled carbon fiber (rCF) and associated applications requires collaboration with a wide range of customers to explore various possibilities for use in specific parts and materials. Toray carbon fiber is applied in the primary structures of the Boeing 787. Off-cuts generated during this production process are turned into rCF, which Lenovo has utilized to make casings for its computers. rCF based on waste CFRP during the production process of Boeing 787 wings is utilized in Lenovo PC casing. Toray Industries has also begun exploring the recycling of scrap and waste materials from customers’ factories for use as recycled carbon fiber (rCF) reinforcement materials. In collaboration with partners, Toray is accelerating product development of high value-added products using rCF, with the aim of realizing a circular economy for carbon fiber.

Carbon fiber offers higher resistance to heat and ultraviolet light and absorbs less moisture than other organic materials. Moreover, carbon fiber can also be produced from biomass-derived raw materials. By leveraging these strengths, Toray Industries aims to build a “Material Eco SYSTEM” for carbon fiber.

Blockchain-based Traceability

Since recycled materials basically have the same physical properties as virgin materials derived from fossil resources, traceability is important for assuring customers that the material has actually been recycled. Therefore, Toray is using blockchain technology to create a traceability system based on manufacturing and transport data from the supply chains of Toray Group products. The technology prevents input data from being tampered with. This system has been set up as a small-scale demonstration.

Click here for the main initiatives for CSR Guideline 7, "Contributing Solutions to Social Issues through Business Activities" in CSR Roadmap 2025.