- HOME

- Sustainability

- CSR Activity Report (CSR Guideline Activity Reports)

- Contributing Solutions to Social Issues through Business Activities

- Initiatives for Sustainability Innovation Business and Product Promotion

Initiatives for Sustainability Innovation Business and Product Promotion

Through its Sustainability Innovation (SI) business, Toray Group is helping to realize a sustainable society. The Group defines the products that constitute its Sustainability Innovation (SI) business as products and technologies that contribute to the four domains outlined in the Toray Group Sustainability Vision, and the products are selected based on the Group’s own criteria.

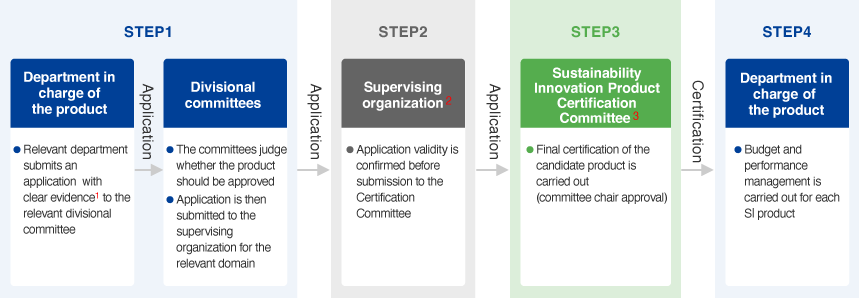

Sustainability Innovation Product Certification Process

To certify its SI products, the Group has established a Sustainability Innovation Product Certification Committee, and products are certified according to the procedures shown in the diagram below.

Based on a three-stage review process involving the relevant divisional committee, supervising organization, and the SI Product Certification Committee, SI products are certified based on objective assessment of their contribution to sustainability.

- 1 In addition to estimates of CO2 emissions reduction attributable to the product, and details concerning the intended applications and materials used, analysis results data based on 1) a product life cycle assessment (a method for quantitatively evaluating environmental impacts throughout the entire life cycle of a product, from resource extraction and material and component manufacturing, to distribution, use, and disposal), as well as 2) a life cycle inventory (a list of environmental impact items and the relevant resource inputs and emission outputs over the life cycle of the product or service)

- 2 Supervising organizations (domains of responsibility):

・Corporate Sustainability Strategic Management Division

Sustainability Business Development Dept. (Circular Economy and Life Innovation)

・Corporate Sustainability Strategic Management Division

Environmental Transition Strategy Dept.(Carbon Neutral and Nature Positive) - 3 Sustainability Innovation Product Certification Committee: SI Business Expansion leader (committee chair: General Manager of Corporate Sustainability Strategic Management Division), General Manager of Corporate Marketing Planning Department, General Manager of Technology Center Planning & Administration Department, as well as external experts when necessary

Sustainability Innovation-Related Products and R&D Announced in Fiscal 2024

Toray Launches TBW-XHR Series Reverse Osmosis Membrane Elements Enabling Ultrapure Water Production from Recycled Wastewater4

Neutral Molecule High-Removal, Low-Pressure RO Membrane Elements “TBW-XHR Series”

Neutral Molecule High-Removal, Low-Pressure RO Membrane Elements “TBW-XHR Series”

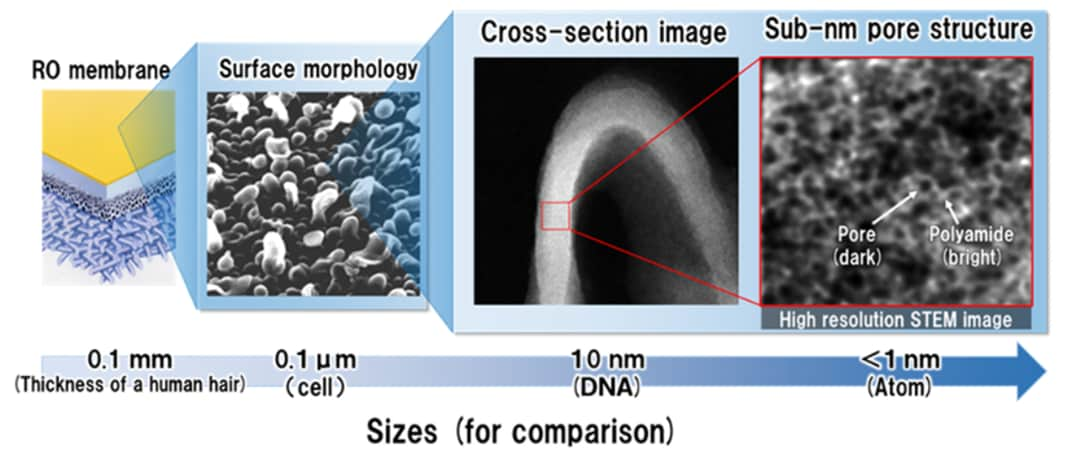

Toray Industries, Inc. has developed the TBW-XHR series of neutral molecule high-removal, low-pressure reverse osmosis (RO) membrane elements. These membrane elements double the urea removal efficiency compared with conventional membranes when using recycled wastewater as a feed source for producing ultrapure water for applications such as semiconductor manufacturing. The Company has begun advance sales to domestic water treatment engineering companies.

With water shortages intensifying worldwide, reusing water in semiconductor manufacturing processes has become a critical issue. This has created demand for technologies capable of producing high-quality ultrapure water from diverse sources such as recycled wastewater and seawater.

Urea, in particular, must be removed with high efficiency because it adversely affects photolithography processes in semiconductor production.

With innovations to RO membrane structure control technology, Toray has developed a new membrane structure control technology that allows selective water permeation and enhances the removal of urea, boron, alcohol, and other substances. This technology doubles the urea removal efficiency, which has been a major challenge, while achieving high water permeability even at low pressure.

Advanced analytical technology from Toray Research Center, Inc. was utilized in developing this product.

Internal evaluations show that the TBW-XHR series achieves a urea removal rate of nearly 90%, reducing urea concentrations by half when producing ultrapure water from recycled wastewater. The product meets the stringent water quality standards required by advanced semiconductor fabs.

In addition to enhancing the water quality of existing ultrapure water production systems, the product could play an important role in constructing new systems, such as those using recycled wastewater. Looking ahead, Toray plans to expand applications to seawater desalination, industrial wastewater treatment, and brackish water desalination from sources such as rivers.

- 4 Recycled wastewater: In recent years, in areas facing severe water shortages, biologically treated wastewater (secondary-treated water) has been further filtered through ultrafiltration and reverse osmosis membranes to produce “recycled water,” which is then used as a source for drinking water and other applications.

Toray Develops High-Precision Hollow Fiber Membrane Module with Nano-Structural Control that Can Streamline Food Production and Reduce Carbon Dioxide Emissions and Costs

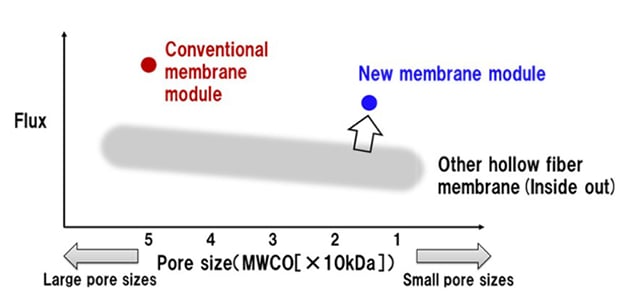

Toray Industries has developed a high-precision hollow fiber membrane module for food and bio-related applications by employing its nano-pore structural control technology. This module features a pore size (molecular weight cut-off5) around one-quarter that of conventional products, while retaining high heat resistance and permeability. This enhances recovery rates and concentration ratios for proteins and polysaccharides, improving production process efficiency while also helping to reduce CO₂ emissions and manufacturing costs.

These products feature an outside-in module, enabling it to handle even highly turbid and viscous liquids. Toray’s proprietary composite hollow fiber membrane structure ensures high permeability and low fouling6. In addition, the module is highly resistant to steam and hot water temperatures of up to 125°C, making it possible to shift from conventional thermal concentration methods to membrane-based concentration, thus helping to cut CO2 emissions.

In recent years, customer demand has grown for technologies, including those for functional foods, that concentrate relatively low-molecular-weight proteins and polysaccharides. By combining its proprietary composite separation membrane with a new manufacturing process retaining the high heat resistance of the membranes, Toray has realized a module that achieves both fine pore size and high permeability. The new products has a molecular weight cut-off of 10,000–20,000 daltons, allowing it to handle a wider range of molecular weights than conventional products.

Toray has begun shipping samples of the new modules to customers, several of whom are conducting assessments. In the future, customers will be able to optimize their production processes by selecting between the new and existing modules depending on the target molecular weight for concentration or purification.

- 5 Molecular weight cut-off: Indicates the ability of a membrane to retain substances of a certain molecular weight

- 6 Fouling: A phenomenon in which contaminants accumulate or block the surface or pores of the separation membrane, impairing its separation performance. Low fouling means the membrane is resistant to such accumulation or blockage.

Applications of new membrane module

Applications of new membrane module Relationship between module’s pore size and liquid permeability (high concentration example)

Relationship between module’s pore size and liquid permeability (high concentration example)

Full-Scale Launch of Nano-Multilayer Window Film that Delivers Both Solar Control and Transparency

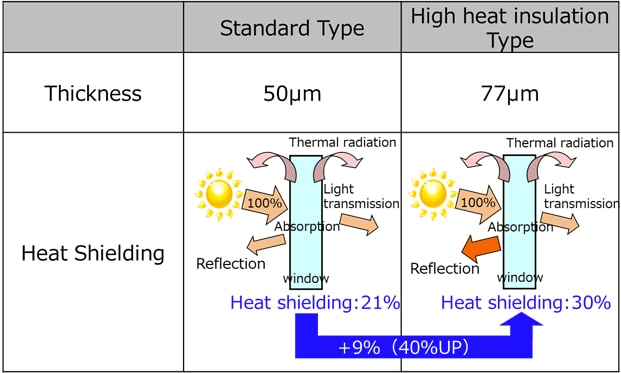

Toray Industries has begun the full-scale rollout of its nano-multilayer film PICASUS™ IR for window film applications. This innovative film combines outstanding solar control performance with glass-like transparency.

In recent years, driven by rising temperatures and the push for energy saving solutions, demand has grown for window films with excellent solar control performance. In particular, in buildings and automobiles, there is a strong need for highly transparent products that do not impair visibility or spoil views.

To meet these needs, Toray developed PICASUS™ IR, a film that offers both transparency and infrared-ray blocking capability through advanced nano-multilayer technology, and has deployed it in applications such as automotive windshields. Leveraging this technology, the Company has now released a new standard type with a thickness of 50 μm, suitable for installation on windows of buildings and automobiles. In addition to its high transparency and solar control performance, it offers excellent rework properties needed during installation.

Toray is also evaluating a high solar-control type with approximately 40% improved solar control performance and is working to expand the product lineup.

PICASUS™ IR also features outstanding electromagnetic wave transmittance, minimizing interference with 5G communications, thereby contributing to both safety and comfort.

Toray Launches International Joint Clinical Trial of RAPROS™ to Treat Chronic Kidney Disease in Cats

Toray Industries carried out an international multicenter clinical trial in Europe for RAPROS™, an oral treatment for chronic kidney disease (CKD) in cats.

Feline CKD leads to symptoms such as loss of appetite and weight loss due to declining kidney function, and ultimately is a life-threatening condition. RAPROS™ is the first veterinary medicine recognized for its efficacy in suppressing the decline of kidney function.

This clinical trial targeted 300 cats with CKD and evaluated the safety and efficacy of RAPROS™ over 182 days, aiming to obtain manufacturing and marketing approval in Europe.

The trial was conducted after securing approval from European countries to conduct a clinical trial, following scientific advice from the European Medicines Agency (EMA).

Concurrently, Toray is pursuing development in other regions, including USA and China.

Exhibition Highlight in Fiscal 2024

Participation in JEC World 2025

Toray Group exhibition booth

Toray Group exhibition booth

Photo by Frederic JOLY / Design by TRIANGLE EXPOSITIONS

Toray Group completed its first joint exhibition by five group companies at JEC World 2025, one of the world’s largest composite material trade shows held in Paris, France, from March 4 to 6, 2025.

Under the theme, “Creating new value and a sustainable future through technology and collaboration,” the Toray Group booth showcased the Group’s vertically integrated structure, a diverse global product lineup, and examples of technology development. Exhibits included TORAYCA™ carbon fiber, towpreg, high-performance thermoset composites, thermoplastic composites, and research and development technologies, broadly communicating Toray’s comprehensive capabilities in the composite materials field.

The exhibits were organized into five categories: Sustainability, Mobility, Energy, Quality of Life, and New Products, highlighting Toray’s product and technology contributions in each area.

Participating alongside Toray Industries, Inc. were European subsidiary companies: Toray Carbon Fibers Europe S.A. (France / manufacturing and sales of carbon fiber and intermediate materials), Toray Advanced Composites Netherlands B.V. (Netherlands / intermediate materials), Composite Materials (Italy) s.r.l. (fabrics and prepregs), and Delta Preg S.p.A. (Italy / prepregs).

This joint exhibition provided a valuable opportunity to demonstrate the strengths of Toray Group’s global business collaboration based on the cooperation of the companies involved.

Award Achievements in Fiscal 2024

Toray’s Water Treatment Membrane Technology Receives Minister of the Environment Prize at the Global Environmental Awards

Toray’s award ceremony attendees (center: President Ohya)

Toray’s award ceremony attendees (center: President Ohya)

Toray Industries, Inc. was recognized for its contribution to solving global water scarcity issues through its water treatment membrane technology, receiving the Minister of the Environment Prize at the 32nd Global Environmental Awards. Toray’s history with water treatment membranes dates back to 1968, when research on RO membranes began. Today, the Company operates 35 sales offices worldwide, six manufacturing plants, and four research and technology development centers. Toray’s water treatment membranes are used in water treatment plants across more than 100 countries. Additionally, following the January 2024 Noto Peninsula earthquake, Toray’s membranes played an active role in producing household and potable water from sources such as ponds in the affected areas.

Toray’s PFAS-Free Technology Wins “GX Award” at nano tech 2025

Professor Tomoji Kawai (left), Chairman of the nano tech Executive Committee, at the GX Award ceremony

Professor Tomoji Kawai (left), Chairman of the nano tech Executive Committee, at the GX Award ceremony

Toray Industries, Inc.’s development of PFAS-free technology was recognized with the Green Transformation (GX) Award at nano tech 2025 (the 24th International Nanotechnology Exhibition & Conference). This marks the Company’s second consecutive year receiving the GX Award since 2023. The award recognized Toray’s promotion of advanced materials and technologies leveraging nanotechnology, contributing to the environmental, semiconductor, and mobility fields, under the main theme of “Toray’s Initiatives toward Innovation Creation.”

Click here for the main initiatives for CSR Guideline 7, "Contributing Solutions to Social Issues through Business Activities" in CSR Roadmap 2025.