- HOME

- Sustainability

- CSR Activity Report (CSR Guideline Activity Reports)

- Safety, Accident Prevention, and Environmental Preservation

- Occupational Safety and Accident Prevention Activities

Occupational Safety and Accident Prevention Activities

Toray Group pursues its own safety activities by establishing and operating an audit system that complies with international standards for occupational health and safety management systems (such as ISO 45001 and OHSAS 18001).

Toray Group employees take part in an introductory training session immediately after joining the Group to learn and demonstrate their level of understanding of specific procedures and internal rules related to occupational safety. For mid-level employees and managers, the Group provides education on management and supervisory responsibility for occupational safety at every type of group training it holds, as well as studies of more concrete case studies related to the occupational health and safety management systems.

In addition, officers in charge of production, as well as production engineering and Environment & Safety Department employees, conduct safety and health, accident prevention, and environment audits of all group companies and plants every year and evaluate and seek improvements in the status of activities from a standardized perspective. Best practices are also shared at sites throughout the Group to enhance the entire Group’s performance.

Employees are key stakeholders of Toray Group. Needless to say, ensuring their safety is the prerequisite to their capacity to make the most of their potential. Officers and employees work together to implement persistent safety initiatives with the goal of zero accidents, out of respect for humanity and the sanctity of life.

To raise the awareness, every year, Toray Group creates a group-wide safety slogan. In 2024, the aim was for each and every employee of Toray Group to come together as a concerted group to raise awareness of safety as the top priority and to ensure that basic safety rules and work fundamentals are thoroughly followed on work sites by upholding the Group slogan—Top Priority is Safety, Pursue “Zero Accidents,” Following the rules and thoroughness in fundamentals. By keeping the same fiscal 2024 slogan for fiscal 2025, the Group is working to further enhance safety awareness and promote strict adherence to safety rules.

Due to the potentially serious impact of an accident not only within the company but on surrounding communities, the Group acts with strong determination to prevent accidents such as fires and explosions, making accident prevention a top priority.

Toray Group sets up safety and health committees and works to ensure the safety and health of its employees through united efforts of labor and management, based on occupational safety and health laws in the countries in which it operates. These efforts help to ensure a pleasant working environment.

2024 Safety Slogan

Top Priority is Safety, Pursue “Zero Accidents”

―Following the rules and thoroughness in fundamentals―

2024 Toray Group Safety Meeting at Toray Human Resources Development Center

2024 Toray Group Safety Meeting at Toray Human Resources Development CenterEvery year, the Toray Industries president, executive vice presidents and other officers, as well as Group company presidents and plant managers meet at the Toray Group Safety Meeting. At the meeting, safety action policies and main activities are shared to set a common course, activities at worksites are reported, and safety awards are given to raise awareness of safety and foster horizontal development for good practices. The Toray Human Resources Development Center was the main venue for this meeting again in 2024. Approximately 600 people attended, including online participants from companies and plants worldwide, who pledged to help achieve a completely accident-free Toray Group in 2025. Furthermore, the Safety Summit, on-site safety lecture by Toray Industries directors, and other events are held on a national and regional basis, and at each group company and plant of the Group. These efforts promote a common awareness of the Toray Group safety slogan, policies, and main activities, enabling centralized management of safety activities across the Group.

In addition, representatives of the senior management and labor unions at Toray Industries hold regular meetings. They discuss issues related to safety and health, establish a shared understanding of the issues, and engage in forward-looking discussions to improve the workplace environment. Safety and health committee meetings are also held at each business site (plant) every month, with the participation of the site head, managers and labor union representatives concerned. They share safety activity policies and give and receive instructions to prevent recurrence of occupational accidents that have recently occurred in Toray Group, while also reporting and discussing other matters related to occupational safety and health.

Opening of the 2024 Health and Safety Conference (slogan chanting) (Toray Construction Co., Ltd.)

Opening of the 2024 Health and Safety Conference (slogan chanting) (Toray Construction Co., Ltd.)![A deputy general plant manager from Toray Plastics Precision (Zhongshan) Ltd. reports on safety activities at the Toray Group South China Regional Safety Conference in China [Toray Industries (China) Co., Ltd.]](images/prevention_p3.jpg) A deputy general plant manager from Toray Plastics Precision (Zhongshan) Ltd. reports on safety activities at the Toray Group South China Regional Safety Conference in China [Toray Industries (China) Co., Ltd.]

A deputy general plant manager from Toray Plastics Precision (Zhongshan) Ltd. reports on safety activities at the Toray Group South China Regional Safety Conference in China [Toray Industries (China) Co., Ltd.]

Examples of Workplace Initiatives in Fiscal 2024

Safety Information Exchange Meeting with Suido Kiko Kaisha [Toray Lycra Co., Ltd. (TLC)]

Activity reports being shared by both companies

Activity reports being shared by both companiesTLC held a safety information exchange meeting with the PE Center of Suido Kiko Kaisha, Ltd. (SKK). During the meeting, the two companies shared information on their safety initiatives and factory cleanup campaigns, followed by a plant tour to see TLC’s plant rejuvenation activities, where they exchanged insights on resourceful approaches and challenges encountered. Examples included improvements to SKK’s break room and outdoor walkways, as well as TLC’s use of QR codes for parts management and the renovation of the women’s changing room and break area. Both companies gained practical knowledge on the implementation and management of factory cleanup and workplace improvements.

Safety Education for Technical Intern Trainees [Toray Industries (H.K.) Vietnam Company Limited (THKVN)]

Training by a Vietnamese instructor at Toray Textiles, Inc.

Training by a Vietnamese instructor at Toray Textiles, Inc.At THKVN, company-wide training sessions were used to provide labor safety education, drawing on actual accident cases that occurred within Toray Group. Fifteen cases translated into Vietnamese were used as discussion material, allowing employees to review risks relevant to their own departments and strengthen safety awareness.

In addition, training sessions were conducted for Vietnamese technical intern trainees working at Toray Group companies in Japan, with Vietnamese staff serving as instructors. The sessions emphasized the importance of safety rules and compliance. The trainees gained a better understanding of safe workplace practices, helping to raise individual awareness.

Toray Group Safety Record

Number of major accidents

- ■Reporting scope

- Toray Group

- ■Target in 2024 (calendar year)

- 0

Result in 2024

1

Number of fire and explosion accidents

- ■Reporting scope

- Toray Group

- ■Target in 2024 (calendar year)

- 0

Result in 2024

3

Achievement for world's best standard for safety management

(not exceeding 0.05 frequency rate for occupational accidents resulting in lost work time)

- ■Reporting scope

- Toray Group

- ■Target in 2024 (calendar year)

- No more than 0.05

Result in 2024

0.25

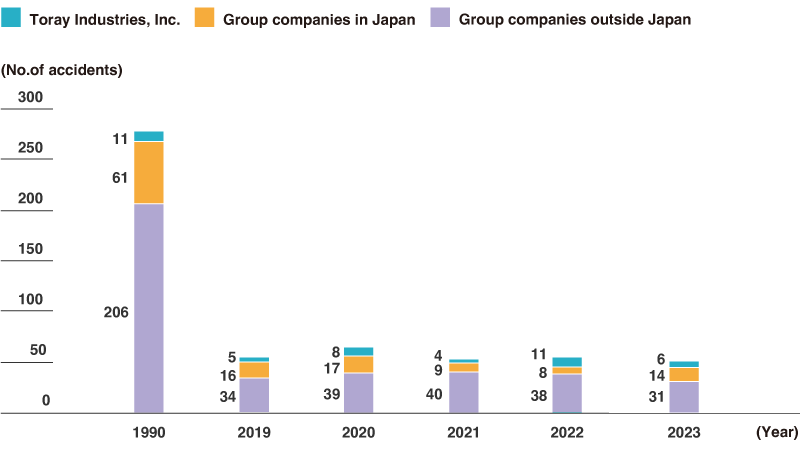

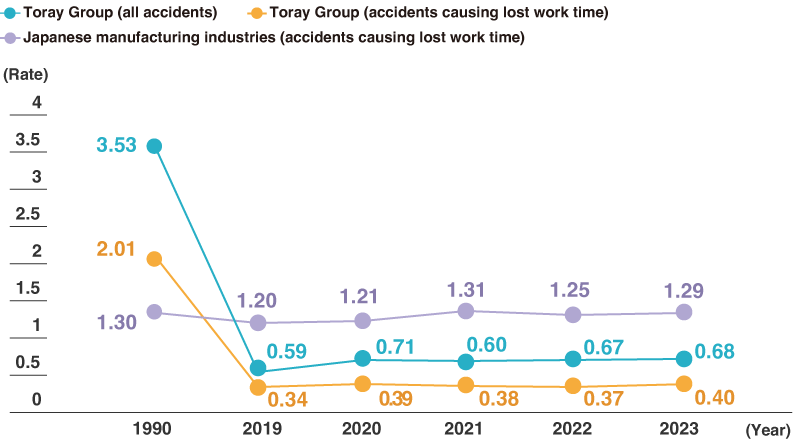

Toray Industries has collected data on all occupational accidents since 1980, and for Toray Group since 1990. Both the number of occupational accidents and frequency of occupational accidents resulting in lost work time have declined, compared with when the data was first collected. The frequency rate for occupational accidents resulting in lost work time for Toray Group overall in 2024 was 0.25. Although this is a positive result compared with that of Japan’s manufacturing industry (1.30), it fell far short of the Group target of achieving the world’s highest standard of safety management of 0.05 or lower.

One reason for this is that group companies had many accidents resulting in lost work time. Accordingly, the Group is working to strengthen safety management at those group companies with support and guidance from Toray’s main plant in Japan.

Toray Group will continue to identify the root cause of each accident to prevent reoccurrence, and avoid similar accidents based on the lessons learned in these accidents. Additionally, the Group will raise employee awareness of the need to practice safety first at all times.

Toray Group believes that safety activities depend upon a repetition of simple things. It is important to commit to the basics of safety and for everyone, without exception, to practice the basics at all times. The first step is to work on the comprehensive implementation of the 5S’s—seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize) and shitsuke (sustain). Through these activities, all employees learn to adopt seiketsu and shitsuke. Seiketsu fosters employees' motivation to keep the workplace standardized and clean, and shitsuke raises employees’ awareness to adhere to the rules. They also take the time to reconsider movement pathways to make work safer. Managers repeatedly go around worksites, praising good behavior in an effort to raise workplace morale.

Next, the Group works to eliminate accidents in routine activities. Managers strive to maintain a sense of alertness in the workplace by continually reminding people to act with safety first, considering what the consequences (accidents) could be under any and all circumstances. In addition, if an occupational accidents does occur, an accident report is sent out to the entire Toray Group. In an effort to eliminate similar accidents, the unit heads and unit chiefs of each workplace take a leading role in discussing the report with workplace team members, imagining the cause of the accident as a specific danger in their own workplace, in order to raise everyone’s safety awareness and ensure commitment to the basics.

- Major accidents

In fiscal 2024, at a group company outside Japan, an accident occurred in which molten polymer was splattered onto employees while they responded to an extruder malfunction, resulting in injuries to multiple individuals. In accordance with internal regulations, the incident was treated as a major accident.

As part of reoccurrence prevention measures, the company first conducted refresher courses on the risks posed by heated polymer splattering and also reviewed protective equipment to ensure such accidents can never reoccur. In addition, in the event of a malfunction such as a machine shutdown, supervisors must be present at the location, personally verify the environmental settings and work procedures required for handling the issue, and provide direct guidance to the employees concerned. - Fire and explosion accidents

While there were no fire or explosion accidents at Toray Industries or group companies in Japan in 2024, there were three such accidents at overseas group companies. These incidents included fires caused by hot work operations and ignition originating from electric utility carts.

In response, the companies where these incidents occurred reinforced communication of the Toray Group’s hot work standards to employees and strengthened inspection of electrical equipment. In an effort to eliminate similar fire-related accidents, the Group has a system to enable Group companies to rapidly share critical information on fire-related accidents. The Group uses knowledge gained from previous accidents to adopt effective fire prevention strategies and implement unified accident prevention management standards.

- 1 Data for Japan includes non-regular employees (part-time employees, contract employees, casual part-timers, and dispatched workers). Data from outside of Japan does not include temporary staff.

- 2 Toray affiliates: Toray Industries’ subsidiaries that provide ancillary services for plant operations

- 3 Occupational accident frequency rate: The number of fatalities and injuries at worksites per one million cumulative working hours.

Identifying Danger (Hazards), Evaluating Risk, and Accident Surveys

- Identifying danger (hazards) and evaluating risk

Toray Group has a system whereby employees report any potential risks in the workplace to managers and the managers provide feedback on countermeasures and improvements. Before starting work, hazard prediction information, near miss reports, and safety proposals are shared with employees to confirm and mitigate risks.

Company inspectors also carry out audits to review the system for preventing occupational accidents and the status of the implementation of countermeasures. If there are any problems, the inspectors give instructions for improvements. - Accident investigation

In the event of an occupational accident, the emergency response review meeting and the countermeasure meeting are convened to clarify the chain of events leading up to the accident, identify the cause, and decide on and execute countermeasures.

In addition, information about the accident is shared throughout the Group and measures taken to prevent a reoccurrence. - Prioritized risk reduction activities

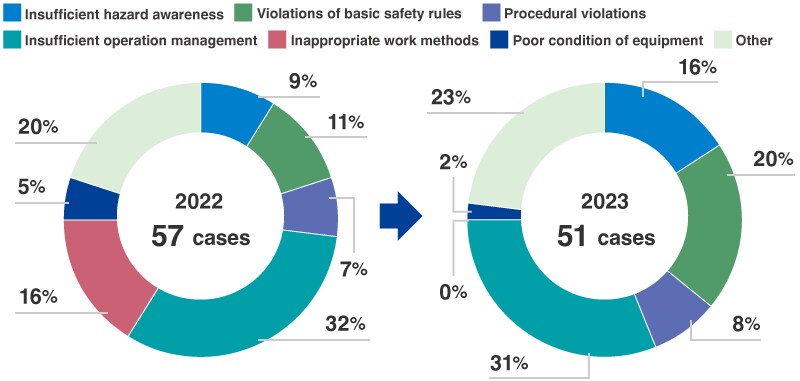

Since 2023, Toray Group has focused on ensuring thorough workplace rule compliance as a main activity. As a result, in 2024, the number of accidents caused by violations of basic safety rules or work procedures was halved, decreasing from 14 cases in the previous year to six. Compliance with rules continues to be emphasized through the Group’s safety slogans, and efforts will continue to achieve zero accidents.

Meanwhile, in 2024, Toray Group promoted thorough pre-work safety checks as a main activity. However, accidents due to insufficient operation management only slightly decreased, from 16 cases to 13. Supervisors will continue to provide detailed instructions on work methods and procedures and ensure that employees fully understand them. In addition, employees are being further instructed to rigorously conduct hazard prediction before starting tasks and to stop work and consult their supervisors if any uncertainties arise during an operation.

In 2025, the Group will continue to analyze the accidents that occurred in 2024 from various perspectives and promote improvement activities aimed at eliminating accidents, by utilizing the plan-do-check-act (PDCA) cycle method.

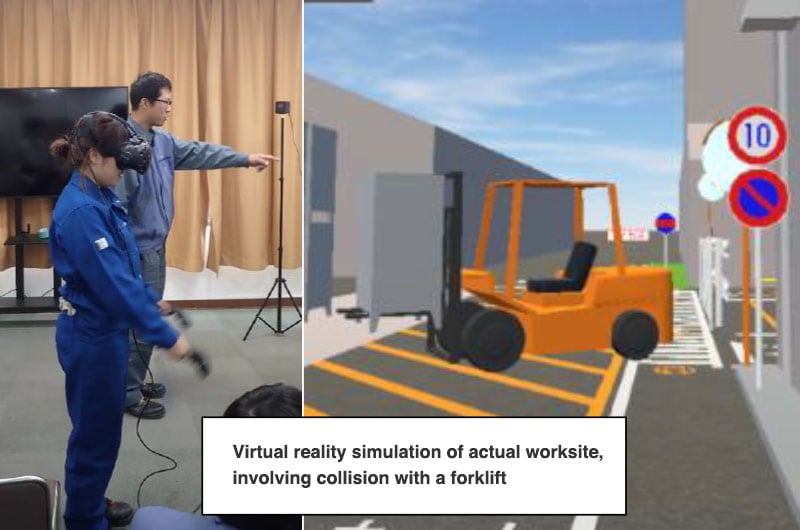

Enhancing Safety and Accident-Prevention Training

As part of their safety and accident prevention training, Toray Group companies and plants provide workshops and hands-on simulations to sensitize employees to dangers and hazards. Safety simulators enable workers to experience the dangers of electrocution, residual pressure, and getting caught in rollers. Virtual reality (VR) technology is also used to realistically simulate accidents at worksites. In the area of accident prevention, the Group conducts simulation training to teach employees about the risk of fires and explosions, and provides training on the fundamentals of accident prevention. Additionally, the Group publishes on familiar topics regarding safety and accident prevention in its in-house magazine, People, in an effort to spread understanding of the fundamentals of accident prevention.

Simulation training at Nagoya Plant (Toray Industries, Inc.)

Simulation training at Nagoya Plant (Toray Industries, Inc.) Demonstrating the danger of fires and explosions at Gifu Plant (Toray Human Resources Development Center)

Demonstrating the danger of fires and explosions at Gifu Plant (Toray Human Resources Development Center)

The Nagoya Plant of Toray Industries carries out production activities across three adjacent factory sites separated by public roads. Due to these narrow roads, nearly 100 of the pipes on the plant premises that supply utilities such as the electricity, steam, and water necessary for production have been installed overhead instead of at ground level. Damage to these pipes can have significant impacts not only on production but also on safety, requiring immediate decision-making and rapid response. However, challenges such as the distances between factories and the risks associated with nighttime high-elevation work had presented many challenges.

To address this, the power engineering section of the facilities department, which manages utility supply at the Nagoya Plant on a 24-hour basis, adopted digital twin technology. This technology converts real spatial information into data and recreates it in a virtual environment on a computer, enabling a more accurate understanding of on-site conditions than drawings alone. It also allows technicians to view each location virtually, almost as if they were physically on-site.

With the adoption of this digital twin technology, equipment and related information can be checked from a desk regardless of the lighting or weather conditions. This has yielded various benefits, including improved safety during inspections and checks, and enhanced work efficiency.

Going forward, the technology will be deployed to other departments and facilities-related divisions, helping to reduce maintenance costs.

| Objective | Specific Cost Reduction Examples and Benefits |

|---|---|

| Efficient capital investment | Reduced on-site survey costs, shorter travel times, faster design work |

| Process stabilization | Improved reliability through detailed maintenance history management, rapid planning and execution of update plans |

| Maintenance efficiency | Inspections of leaks and repairs, greater safety when working at height, confirmation of environmental settings, careful review of estimates |

| Human resource development | On-site training and work inspections unaffected by weather or time of day, self-directed learning, technical skill transfer to younger employees, traffic safety education |

Utility pipelines at Plants 1, 2 and 3

Utility pipelines at Plants 1, 2 and 3 Pipelines installed overhead

Pipelines installed overhead

Functions of various pipelines are made clear on the computer screen using 18 different colors

Functions of various pipelines are made clear on the computer screen using 18 different colors Spatial simulations are also possible using virtual reality technology

Spatial simulations are also possible using virtual reality technology

This initiative was recognized with the Group’s First Steps Award. The annual award program seeks to encourage individual employees to take on new challenges.

Related Information

Implementing Safety Management Together with Subcontractors

Participants learn pre-operation forklift inspections and basic driving techniques and engage in hands-on training (Ogaki Fuso Spinning Co., Ltd.)

Participants learn pre-operation forklift inspections and basic driving techniques and engage in hands-on training (Ogaki Fuso Spinning Co., Ltd.)Toray Industries implements uniform safety activities for its own work as well as subcontracted work that is subcontracted to on-site Toray affiliates and Group companies. Monthly occupational health and safety committees and regular safety and liaison meetings are used to discuss the implementation status of safety activities and enhance communication with subcontractors, to ensure that all parties are aligned in the implementation of safety activities. Employees conduct on-site monitoring of operations in practice such as those involving forklifts and sharp-edged objects and use the results to generate recommendations for necessary improvements that enhance safety and ease of work. Subcontractors also submit their requests for work and equipment improvements, to increase physical safety.

Safety Management Implemented by Subcontractors

Reports from each department are delivered at a safety conference attended by group and partner companies at the plant (Toray Industries, Inc. Gifu Plant)

Reports from each department are delivered at a safety conference attended by group and partner companies at the plant (Toray Industries, Inc. Gifu Plant)Toray Group recognizes its duty to ensure the safety of the many subcontractors working at its sites. As colleagues working in the same workplace, subcontractors are made aware of, and expected to comply with, Toray Group rules. Subcontractors also participate in monthly meetings of occupational safety and health committees. Regular safety and liaison meetings are conducted to gain input from subcontractors and are used to communicate the Group's policies and to make sure all measures are implemented. In addition, the Group educates subcontractors who work on a short-term basis about Toray Group rules before work commences and manages safety thoroughly. At plants, Toray and subcontractors work together on safety initiatives, including safety posters, slogan contests and safety suggestions.

Preparing for Accidents through Fire-Prevention Drills

All companies and plants in Toray Group are making efforts to improve their accident-prevention capabilities by carrying out fire-fighting drills specifically tailored to each type of fire and explosion. These drills include practice using water hoses, rescuing the injured, responding to a chemical leak, and giving emergency notification to authorities and local residents. Since 2012, Group companies and plants have been conducting annual drills on setting up a company-wide emergency headquarters in response to a large-scale earthquake. The drills also involve checking on employees and monitoring facilities damage and supply chains. The Noto Peninsula Earthquake in January 2024 impacted the Toray Industries Ishikawa Plant and Sowa Textile Co., Ltd. Learning from this experience, the Group established its Fundamental Policy in the Event of a Major Earthquake, which prioritizes preservation of human life above all else. Based on this policy, each company and plant conducts drills for the initial response to a large-scale earthquake, while group plants in seaside locations conduct drills of the evacuations that would be needed if a tsunami were triggered by a large-scale earthquake.

Fire prevention training (Toray Monofilament Co., Ltd.)

Fire prevention training (Toray Monofilament Co., Ltd.) Firefighting training (Toray Textiles, Inc.)

Firefighting training (Toray Textiles, Inc.)

Disaster prevention training at a petrochemical complex (Toray Industries, Inc. Nagoya Plant)

Disaster prevention training at a petrochemical complex (Toray Industries, Inc. Nagoya Plant)

Initiatives for Improving Fire-Prevention Capabilities

Toray Group is further enhancing its disaster prevention capabilities. In 2024, as part of the regularly held activities to strengthen fire prevention for the Fire Prevention Project Part II, Toray Group in Japan conducted certification training for FP4 key persons, who play a pivotal role on the frontlines by promoting accident prevention inspections and measures. As a result, a total of 493 individuals were newly certified. Toray Group’s internal accident prevention experts provided support and guidance in identifying the root cause and taking countermeasures to prevent reoccurrence of those fire accidents and near misses for which the experts decided onsite audits and investigations were necessary.

Furthermore, when responding to a large-scale earthquake, the Group’s basic policy is to prioritize human life, taking into consideration not only the seismic intensity but also the impact of aftershocks, the securing of sufficient personnel, and the emotional well-being of our employees and their families. The Toray Group Business Continuity Plan (BCP) for a Large-Scale Earthquake outlines the emergency response to an earthquake and subsequent activities to maintain and restore business operations, as well as the Group’s duties and normal readiness. In particular, for critical products, the Group develops BCPs that encompass supply chains and continually works to reduce risks.

- 4 FP : Fire Prevention

Examples of Workplace Initiatives in Fiscal 2024

Earthquake Preparedness Drills

Toray Group, with the cooperation of local fire departments and other organizations, conducts fire and earthquake drills with group companies and local residents.

Evacuation drill using a simulated smoke-filled house (Toray Industries Inc. Mishima Plant)

Evacuation drill using a simulated smoke-filled house (Toray Industries Inc. Mishima Plant) Rescue training using a simulated collapsed house (Toray Industries Inc. Seta Plant)

Rescue training using a simulated collapsed house (Toray Industries Inc. Seta Plant)

Distribution Safety Initiatives

Toray Industries is working to ensure safe distribution in its operations. In an effort to manage safety when transporting hazardous substances, the Company concludes security agreements with certain customers, raw material manufacturers, and shipping companies to designate their specific safety responsibilities and roles with regards to safety.

Initiatives to Reduce Health Effects of Chemical Substances on Employees

In consideration of the health risks to employees, including contracted, part-time, and dispatched employees, Toray Group is implementing the following initiatives for the handling of chemical substances.

- Study the actual handling of chemical substances

Toray Group collects annual data on the volume of chemical substances handled by offices and plants of Group companies and volume in their possession. Furthermore, the Group clearly indicates the danger of mutagenicity for each chemical substance as stipulated in the Industrial Safety and Health Act, and discloses the risks. - Implement chemical substance risk assessments

Toray Group implements risk assessments using a variety of tools, which include working environment measurements for the chemical substances that it handles, ECETOC Targeted Risk Assessment (TRA), CREATE-SIMPLE assessments, and control banding. The risk assessment results are used to protect the health of employees by implementing comprehensive measures to prevent worker exposure to organic solvents and dust where it is required. - Conduct follow-up through internal audits

Toray Group conducts an annual safety, health, accident prevention, and environmental audit, to objectively evaluate the methods for handling chemical substances and working conditions. The audit is used to identify any oversights or unattended issues and implement necessary improvements. - Other

Toray Group endeavors to maintain and improve working conditions by conducting working environment measurements and on-site monitoring of actual work in accordance with the risk level of handled substances. It also conducts medical checkups to continually follow-up on the health status of employees. To prevent health issues among workers, the Group conducts training on the dangerousness of handled chemicals, and prepares and keeps records of the on-site monitoring of actual work.

Health Effects and Response to Asbestos

Toray Group has manufactured and imported building materials containing asbestos in the past. In addition, certain buildings and facilities were constructed using such materials and thermal insulation containing asbestos. Starting in 2005, when asbestos-related health hazards became a social concern in Japan, Toray took action to address the issue of its own asbestos-containing facilities. The health program offers medical examinations to current and former employees who handled even small amounts of asbestos and wish to undergo an examination. Toray Group is working in good faith with individuals diagnosed with asbestos-related health issues by assisting with their applications for workers' compensation and providing an ongoing program of medical examinations. The Group has not been contacted about health issues by residents living near affected plants.

The cumulative health impacts on former and current Toray Group employees as of March 31, 2025 are as follows.

Medical examination recipients involving asbestos (Toray Group): 4,045

Certified occupational accidents arising from handling asbestos (Toray Group): 140 (124)*

Certified health victims based on Japan's Act on Asbestos Health Damage Relief (Toray Group): 8 (8)*

- * Figures in parentheses refer to fatalities as of March 2025.

Click here for the main initiatives for CSR Guideline 3, "Safety, Accident Prevention, and Environmental Preservation" in CSR Roadmap 2025.