The completed plant

Membrane bioprocess is a technology that would enable the reduction of energy for separation and refinement by using membranes in the saccharification and fermentation and to improve conversion efficiency of non-edible biomass. It will contribute to make a supply chain for various biochemicals from non-edible biomass.

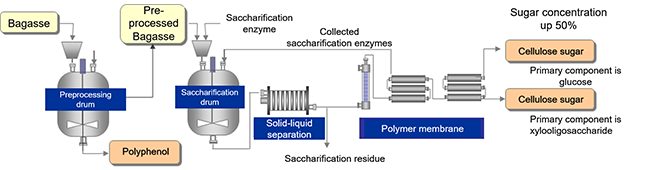

The demonstration plant will use the residual bagasse as an ingredient and efficiently co-produce cellulosic sugar, which is a fermenting raw material for bioethanol, lactic acids and succinic acid, and high value added products such as polyphenol and oligosaccharide (diagram). The plant is expected to start operations in late July 2018. By applying the membrane separation technology from Japan, the plant aims to reduce energy consumption more than 50% compared with the conventional manufacturing system, which concentrates sugar solution by evaporating water.

Going forward, Toray will continue running the demonstration plant till fiscal year 2022 (as per plan) to assess and verify the impact on energy savings, product performance, economic viability of the system, etc. Also, Toray will hold educational seminars and PR activities regarding energy-saving useful material production technologies employing polymer membrane technology to disseminate the system to Thailand as well as to the other ASEAN countries.

Toray places environment as the linchpin of its business strategy so as to contribute to the realization of a sustainable low-carbon society, and under this management policy, the company has established itself as a pioneering comprehensive chemical manufacturer in Japan to promote LCM3 environment management based on the LCA concept.

As part of this endeavor, Toray will actively pursue open innovation (collaboration and fusion) of membrane-based bioprocessing between different industries and drive forward the development of supply chain and provisioning of solutions.

| [Company profile] |

| 1. Name |

Cellulosic Biomass Technology Co., Ltd. (CBT) |

| 2. Location |

Headquarters: Bangkok, Thailand; Business Office: Udon Thani Province, Thailand |

| 3. Established |

January 2017 |

| 4. Capitalization |

680 million baht |

| 5. Investments |

Toray Group |

: 456 million baht [67% stake] |

|

Mitsui Sugar |

: 224 million baht [33% stake] |

| 6. Business |

Technological demonstration of cellulosic sugar production process using membranes |

|

|

|

| [Diagram] |

Production flow of cellulose sugar, oligosaccharides and polyphenols from bagasse

Production flow of cellulose sugar, oligosaccharides and polyphenols from bagasse

| [Explanation of terms] |

| 1) Cellulosic sugar: |

|

Sugar solution, with glucose as its main component, obtained by hydrolyzing cellulose in inedible biomass. |

| 2) Bagasse: |

|

The solid matter that remains after extraction of juice from sugarcane. Bagasse is burnt in the boiler of the sugar plant and recycled as electrical energy. The remaining bagasse left unused is defined as surplus bagasse. |

| 3) LCM environment management based on LCA concept: |

|

Life Cycle Management, or LCM is a sustainable initiative aimed at improving a business’s economic and social values, while reducing the environmental burden, by viewing a product or service from the perspective of its entire life cycle (Life Cycle Assessment, or LCA) in various industrial and corporate activities. |