- HOME

- Sustainability

- Safety, Accident Prevention, and Environmental Preservation

CSR Activity Report (CSR Guideline Activity Reports)

Safety, Accident Prevention, and Environmental Preservation

Ensure the safety and health of society and employees, and protect the environment in all business processes, from procuring raw materials and manufacturing to the supply and disposal of products.

Basic Approach to Environmental Preservation

Corporate efforts to help realize a sustainable society have become increasingly vital in recent years. Toray Group established its Medium-Term Environmental Plan in fiscal 2000 to strengthen and enhance initiatives for reducing environmental impact. The Group has set key performance indicators (KPIs) to reduce greenhouse gas emissions per unit of sales in order to fight global warming, as well as to reduce atmospheric emissions of certain chemical substances (PRTR substances and VOCs, etc.) and waste. These efforts have continued during the course of all five Medium-Term Environmental Plans up until fiscal 2020.

Under the Toray Group Sustainability Vision announced in July 2018, the Group aims to achieve two targets per unit of revenue by 2030: a 30% reduction in greenhouse gas emissions from production activities and a 30% reduction in water usage, both compared with fiscal 2013.

Under the medium-term management program Project AP-G 2022, which covers the period from fiscal 2020 to fiscal 2022, the Group promoted the Challenge 30 Project, a company-wide project to tackle specific activities to realize the Toray Group Sustainability Vision of reducing greenhouse gas emissions and water consumption per unit of revenue. To achieve these two targets, three-year KPIs were included in CSR Roadmap 2022, the Group's medium-term CSR plan, and initiatives were implemented to meet the targets. With these efforts, the Group met its targets for fiscal 2030 ahead of schedule in fiscal 2022. Therefore, to further accelerate its activities to realize a sustainable world, the Group significantly raised the numerical targets in the Toray Group Sustainability Vision from the 30% reduction to a more than 50% reduction in both greenhouse gas emissions and water consumption per unit of revenue compared to fiscal 2013. The Group is also accelerating efforts by setting the target of reducing greenhouse gas emissions in Japan by at least 40% compared to fiscal 2013.

To meet the new targets, three-year KPIs have been included in CSR Roadmap 2025, which covers the period from fiscal 2023 to fiscal 2025. The company-wide Challenge 30 Project has also been renamed the Challenge 50+ Project to further promote reduction efforts through routine energy-saving activities, the introduction of renewable energy, elimination of the use of coal, and other means. Moreover, in addition to reducing greenhouse gas emissions and water consumption per unit of revenue, CSR Roadmap 2025 also continues to set KPIs relating to atmospheric VOC emission reduction and waste recycling rate improvement. The Group is taking steps to meet these, including by strengthening its management of priority-focus companies and factories, namely those have a particularly large environmental impact.

- * Refer to the following activity reports for more information on basic approaches and policies regarding safety and disaster prevention, as well as for issue awareness and policies regarding individual environmental issues.

Related Policies

Ten Basic Environmental Rules (Established January 2000 and revised June 2011)

- 1. Prioritize environmental preservation

We shall comply with all laws, regulations, and agreements in all of our business activities. Taking biodiversity into consideration, we shall place the highest priority on environmental preservation in the manufacture, handling, use, sale, transport, and waste disposal of products. - 2. Prevent global warming

We shall promote energy conservation and work to reduce our unit energy consumption and our carbon dioxide emissions. - 3. Achieve zero emissions of environmental pollutants

We shall strive continuously to reduce our emissions with the ultimate goal of achieving zero emissions of hazardous chemical substances and waste materials into the environment. - 4. Use safer chemical substances

We shall collect, maintain, and provide information on the health and environmental effects of the chemical substances we handle while striving to use safer chemical substances. - 5. Promoting Recycling

We shall develop recycling technologies for products, containers, and packaging and cooperate with society in promoting the recovery and reuse of such items. - 6. Improve the level of environmental management

We shall work to maintain and improve the level of our environmental management while working to upgrade our environmental management technology and skills, performing self auditing, and taking other measures. - 7. Contribute to society through environmental improvement technologies and products

We shall meet the challenge of developing new technologies and shall contribute to society through environmental improvement technologies as well as products that place a low burden on the environment. - 8. Improve the environmental management of our overseas businesses

In our overseas business activities, we shall place top priority on complying with local laws and regulations, and further, we shall manage those businesses in accordance with the management standards of the Toray Group. - 9. Improve employees' environmental awareness

We shall strive to improve our employees' awareness of environmental issues through environmental education, social activities, internal communications activities, and other means. - 10. Share environmental information with society

We shall deepen mutual understanding of Toray Group environmental policies and practices by widely publicizing our environmental preservation efforts and their results in environmental reports and other publications directed at local communities, investors, and the media.

Safety, Health, Accident Prevention and Environmental Preservation Management

Action Policy and Main Activities

Toray Group operates a policy for safety, health, accident prevention, and environmental activities. The policy is revised every year to reflect the results from the previous fiscal year, and specifies the main activities to implement in each policy area.

Safety, Health, Accident Prevention, and Environment Activity Policy of Toray Group in 2022

| Action policy | Main activities | |

|---|---|---|

| Safety | Pursue zero occupational accidents |

|

| Healthier lives | Emphasize occupational health management |

|

| Accident prevention | Pursue zero fire accidents |

|

| Enhance crisis management for natural disaster risks |

|

|

| Environment | Pursue zero environmental accidents |

|

| Promote Sustainability Vision |

|

|

- 1 3S/5S: 3S stands for seiri (sort), seiton (set in order), and seiso (shine). Adding seiketsu (standardize) and shitsuke (sustain) to 3S make up 5S.

Structure

Safety, Health, Accident Prevention, and Environmental Preservation Promotion System

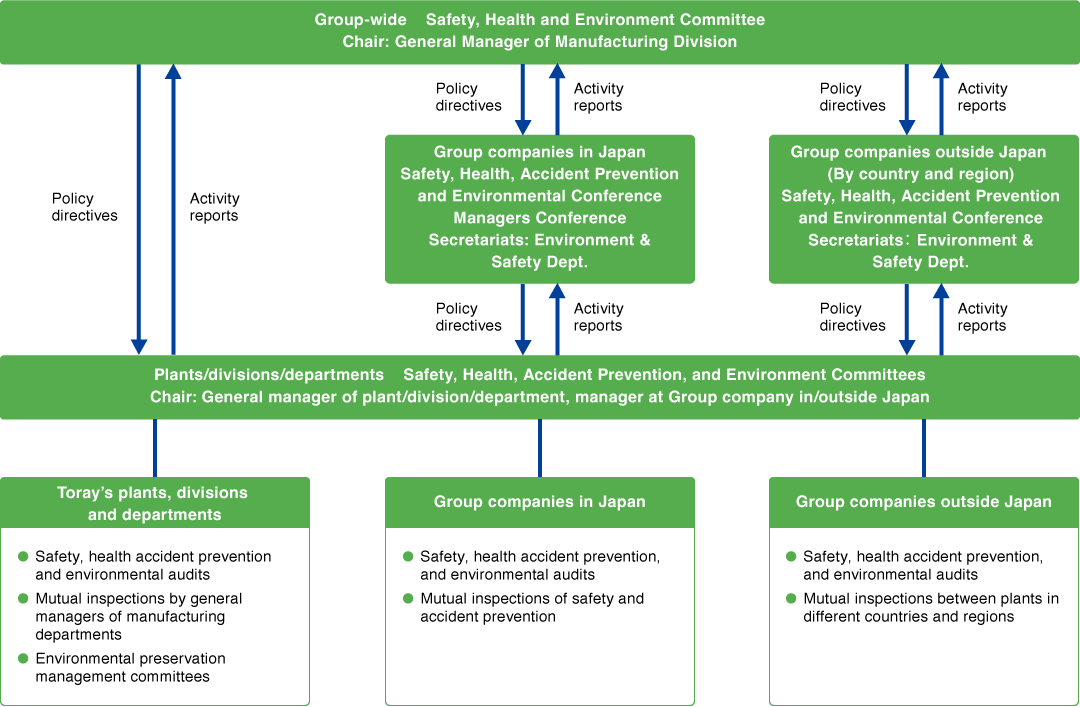

Toray Industries, Inc. places a group-wide committee, namely the Safety, Health, and Environment Committee, at the top of its system for safety, health, accident prevention, and environmental preservation (see chart below). The committee meets annually.

The committee discusses and sets policies and strategies for the entire Toray Group and its Responsible Care initiatives. The chair of the committee2 has absolute responsibility and authority over these matters. Progress on the issues determined by the committees is managed in the business divisions and plants using the PDCA cycle.

- 2 As of July 2023, the executive vice president (member of the board) serves as chair of the Safety, Health, and Environment Committee.

Audits and Follow-Up Measures

Toray Group conducts annual audits to objectively assess and improve the execution and management of safety, health, accident prevention, and environmental initiatives at offices and plants of group companies. Internal audits are conducted using a standardized audit checklist, and encompass visits and production floor guidance provided by directors and managers from other group companies.

In fiscal 2022, audits were conducted for all 13 plants and one research laboratory at Toray Industries, 27 plants operated by 27 group companies in Japan, and 83 plants operated by 64 group companies outside Japan. The audits focused on the following areas: safety measures for work related to rotating parts; prevention of electrical fires and spontaneous combustion from heat storage with heat insulating materials; and thoroughness of measures to prevent environmental accidents. The audits helped to secure systematic improvements by identifying and addressing facility issues and issues relating to management.

ISO 14001 Certification

Toray Group is pursuing the acquisition of ISO 14001, the certification for environmental management system, by all of its group companies, offices, and plants. Toray Industries had completed accreditation for all 13 of its plants by the end of 2000. By fiscal 2022, 32 plants at 23 group companies in Japan and 68 plants at 49 group companies outside Japan were certified.

In fiscal 2022, Toray Celanese Co. Ltd., a newly established company in Japan, was added to the scope of certification, and Toray Industries (India) Private Limited acquired certification for the first time, increasing the total by two companies and two plants.

Related Information

CSR Roadmap 2022 Targets

CSR Roadmap goals

- Place the highest priority on safety, thoroughly uphold the basic rules, and strive to prevent disasters and accidents

- Reduce environmental impact by working to fulfill the Medium-Term Environmental Plan

- Pursue environmental and biodiversity preservation on the basis of policies on water resources and biodiversity

Main Initiatives and Key Performance Indicators

KPI |

|

Safety |

|

⑴ Aim for zero major accidents |

3-❶ |

⑵ Achieve world’s best standard for safety management |

3-❷ |

⑶ Create a comfortable working environment to ensure the safety and health of employees and to raise the level of safety and health |

- |

Accident Prevention |

|

⑷ Aim for zero fire and explosion accidents |

3-❸ |

Environmental Prevention |

|

⑸ Aim for zero environmental accidents |

3-❹ |

⑹ Reduce greenhouse gas emissions per unit of revenue |

3-❺ |

⑺ Reduce water consumption per unit of revenue |

3-❻ |

⑻ Reduce atmospheric VOC3 emissions |

3-❼ |

⑼ Aim for a high waste recycling rate |

3-❽ |

⑽ Conduct a survey of palm oil contained in raw materials and switch to certified products |

3-❾ |

⑾ Systematically adopt renewable energy |

- |

⑿ Reduce atmospheric emissions of substances subject to the PRTR Act4 |

- |

⒀ Pursue the greening of each site in consideration of the regulations of each country and region and harmony with the surrounding environment |

- |

| Key Performance Indicator (KPI) | Target | Fiscal 2022 Result | ||

|---|---|---|---|---|

| Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | ||

| 0 | 0 | 0 | 0 | |

| No more than 0.05 | No more than 0.05 | No more than 0.05 | 0.37 | |

| 0 | 0 | 0 | 2 | |

| 0 | 0 | 0 | 7 | |

| At least 20% lower than fiscal 2013 (Fiscal 2022) | 34.6%5&6 | |||

| At least 25% lower than fiscal 2013 (Fiscal 2022) | 31.9%6 | |||

| At least 70% lower than fiscal 2000 | At least 70% lower than fiscal 2000 | At least 70% lower than fiscal 2000 | 70.9% | |

| At least 86% | At least 86% | At least 86% | 86.8% | |

| Usage survey of certified products : 100% | Decision making (Yes/No) of shifting to certified raw materials : 100% (Fiscal 2022) | 100% | ||

- Reporting scope : Toray Group (3-❶, 3-❷, 3-❸, 3-❹, 3-❺, 3-❻, 3-❼ and 3-❽)

Toray Industries, Inc. (3-❾)

- 3 Volatile organic compounds

- 4 Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof

- 5 Until FY 2022, this was calculated by multiplying the GHG emissions and revenue of individual subsidiaries worldwide by the applicable Toray Industries' equity share. Starting in FY 2023 however, the calculation method will change, and the degree of financial control Toray Industries has over the individual subsidiary (not the equity share) will be used, in accordance with the GHG Protocol, the international standard. Under the latter calculation method, the reduction is 32.7%.

- 6 The calculation of the figure for the baseline of FY 2013 includes data for companies that joined the Toray Group in FY 2014 or later.

Related Materiality for CSR

- Accelerating Climate Change Mitigation

- Promoting a Circular Economy

- Taking a Nature-Positive Approach

- Ensuring Safety and Fire Accident prevention

Looking to the Future

Toray Group will continue to carry out safety, accident prevention and environmental preservation activities based on international frameworks such as ISO 14001 and Responsible Care as well as the Group’s medium- and long-term and single-year goals. The Group is committed to protecting the health and safety of employees and the public and reducing its environmental impact.

Click here for the main initiatives and KPIs for CSR Guideline No. 3 “Safety, Accident Prevention, and Environmental Preservation” during the CSR Roadmap 2025 period (fiscal 2023–2025).

Activity Reports and Environmental Data

Click bellow on activity reports for fiscal 2022.

Activity Reports

- Occupational Safety and Accident Prevention Activities

- Conserving Energy and Reducing Greenhouse Gas Emissions

- Chemical Management

- Voluntary Initiatives to Reduce Atmospheric Emissions of Chemical Substances

- Initiatives to Prevent Air and Water Pollution

- Initiatives for Managing Water Resources

- Initiatives to Reduce Waste

- Environmental Risk Management

- Environmental Accounting

- Biodiversity Initiatives

Environmental Data

- Environmental Impact Overview

- Chemical Substance Emissions and Transfer Data

- Sites with ISO 14001 Certification

- Environmental Data for Toray Industries and Principal Group Companies