- HOME

- Sustainability

- Safety, Accident Prevention, and Environmental Preservation

- Initiatives to Prevent Air and Water Pollution

CSR Activity Report (CSR Guideline Activity Reports) - Safety, Accident Prevention, and Environmental Preservation

Initiatives to Prevent Air and Water Pollution

Toray Group works continuously on environmental conservation measures at its production sites. It is working to prevent air pollution caused by volatile organic compounds (VOCs), sulfur oxides (SOx), nitrogen oxides (NOx), and dust emissions, as well as to prevent water pollution by reducing biochemical oxygen demand (BOD) and chemical oxygen demand (COD). Given that Toray Group processes involve many organic chemicals, reduction of atmospheric VOC emissions has been identified as a top priority. Under the Group’s CSR Roadmap 2025, covering fiscal years 2023 to 2025, KPIs have been established to drive this initiative. Going forward, the Group will continue efforts to reduce VOCs and other air pollutants by installing recovery systems and switching fuels. It will also keep decreasing BOD and COD through stable operation and expansion of wastewater treatment facilities.

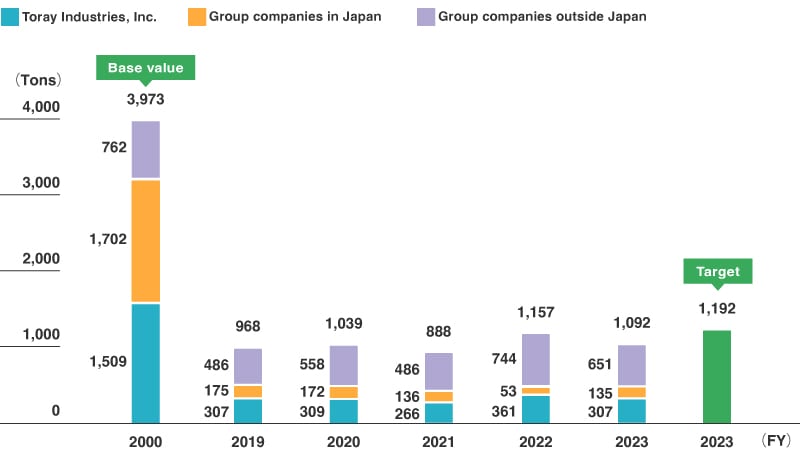

Reduction of Atmospheric VOC Emissions

Reduction of atmospheric VOC emissions (%)

- ■Reporting scope

- Toray Group

- ■Target in fiscal 2023

- At least 70% lower than fiscal 2000

Result in fiscal 2023

72.5%

In fiscal 2023, Toray Group’s atmospheric VOC emissions were 1,092 tons, down 5.6% (65 tons) compared to the previous fiscal year.

The emissions were 72.5% below the base year of fiscal 2000, achieving the CSR Roadmap 2025 target of a 70% reduction compared to the base year.

Going forward, as it works on business expansion, the Group will keep striving to achieve the KPI set under the CSR Roadmap 2025, namely, an annual reduction target of 72% or more compared to fiscal 2000. To achieve this goal, the Group will designate companies with high VOC atmospheric emissions as companies subject to supervision and work with these companies to further reduce emissions.

The Group will also keep voluntarily reducing atmospheric emissions of substances subject to the PRTR Act, which include chemicals of concern due to potential health impacts, while closely monitoring regulatory trends in each country or region where its production sites are located.

In fiscal 2023, total atmospheric emissions of PRTR-regulated substances across the Toray Group amounted to 924 tons. This represented a 64.8% reduction compared to the base year of fiscal 2000.

Air Emission Management (Fiscal 2023 Result)

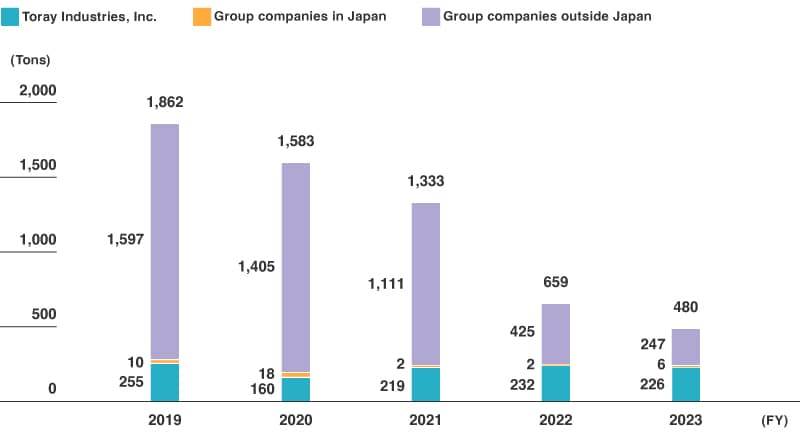

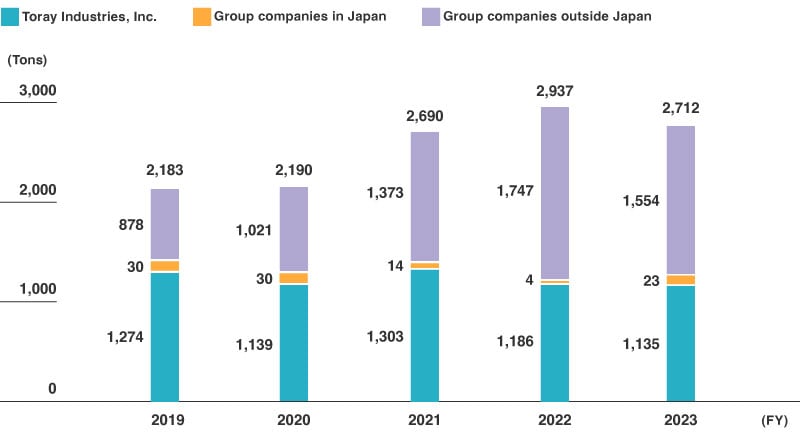

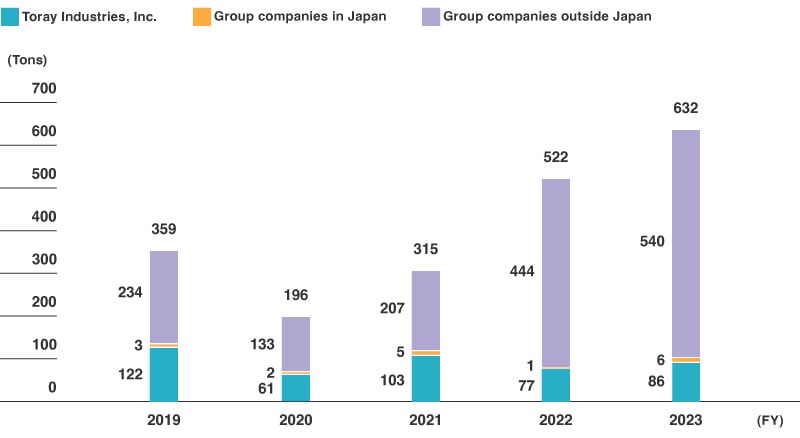

In fiscal 2023, Toray Group recorded 480 tons of SOx emissions (down 27% year on year), 2,712 tons of nitrogen oxide (NOx) emissions (down 8% year on year), and 632 tons of dust emissions (up 21% year on year). The year-on-year reduction in SOx and NOx emissions was due to the downsizing of coal-fueled boilers at group companies outside of Japan. The year-on-year increase in dust emissions was due to changes in fuel type.

Wastewater Quality Management (Fiscal 2023 Result)

Toray Group monitors and complies with regulations concerning BODs, CODs, and nitrogen in countries and regions where it operates plants and implements water quality management for plant wastewater. Plants with high effluent loads are reducing effluents by installing wastewater treatment facilities (activated sludge method) that utilize the activated sludge method and other techniques. The Group is committed to remaining in compliance with regulations through everyday facilities operation management and regular self-testing of water quality.

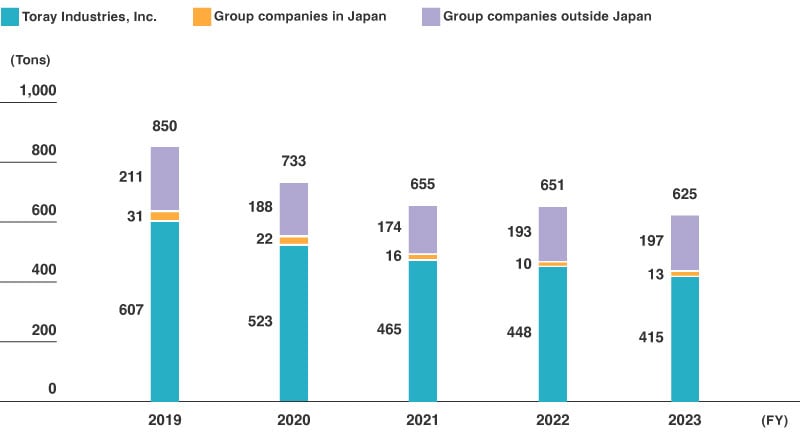

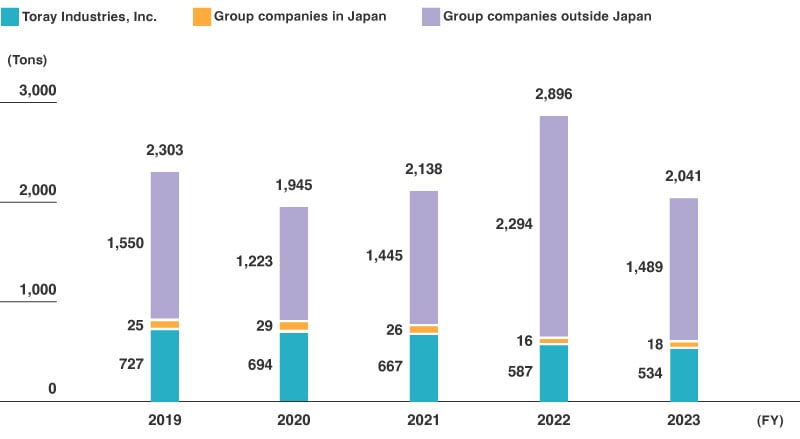

In fiscal 2023, Toray Group recorded 625 tons of BOD emissions (down 4% year on year) and 2,041 tons of COD emissions (down 30% year on year). BOD and COD emissions improved from the previous year due to enhancement of wastewater treatment process efficiency and other efforts.

Moving forward, Toray Industries will further strengthen the technical support provided to group companies to achieve greater reduction of effluent loads.

The Group brings together wastewater managers every year to share and discuss strategies for enhancing wastewater management at production sites. The fiscal 2023 meeting was attended by 42 persons from Toray Industries’ plants and 33 persons from group companies in Japan.

The Toray Industries Ehime Plant uses the activated sludge method to treat and detox wastewater before discharge, as it contains chemical substances from each production process.

Previously, excess sludge was either composted or disposed of after fermentation treatment. However, based on an idea from the wastewater treatment team, the plant launched a Blooming Flowers Project in August 2023, and began using its excess sludge and treated water to grow flowers.

If antimicrobial agents and detergents are not effectively removed from the plant’s wastewater, they can cause the flowers to wither, so water quality management is now even more rigorous. By cultivating flowers, employees can visually confirm the treated water’s safety, which also enhances water quality management.

Utilizing excess sludge in this way has helped reduce the plant’s industrial waste by approximately three tons per year.

This initiative was recognized with the Group’s First Step Award in 2023. The award program seeks to encourage individual employees to take on new challenges.

Wastewater treatment using the activated sludge method

Wastewater treatment using the activated sludge method Blooming Flowers Project zone next to the water treatment facility

Blooming Flowers Project zone next to the water treatment facility

Related Information

Click here for the main initiatives for CSR Guideline 3, “Safety, Accident Prevention, and Environmental Preservation” in CSR Roadmap 2025.