- HOME

- Sustainability

- Safety, Accident Prevention, and Environmental Preservation

- Occupational Safety and Accident Prevention Activities

CSR Activity Report (CSR Guideline Activity Reports) - Safety, Accident Prevention, and Environmental Preservation

Occupational Safety and Accident Prevention Activities

Toray Group pursues its own safety activities using occupational health and safety management systems (such as OHSAS 18001 and ISO 45001). Toray Group employees take part in an introductory training session immediately after joining the Group to learn and demonstrate their level of understanding of specific procedures and internal rules related to occupational safety. For mid-level employees and managers, the Group provides education on management and supervisory responsibility for occupational safety at every type of group training it holds, as well as studies of more concrete case studies related to the occupational health and safety management systems. In addition, officers in charge of production, as well as production engineering and Environment & Safety Department employees, conduct safety and health, accident prevention, and environment audits of all group companies and plants every year and evaluate and seek improvements in the status of activities from a standardized perspective. In addition, best practices are shared at sites throughout the Group to enhance the entire Group’s performance.

Employees are key stakeholders of Toray Group. Needless to say, ensuring their safety is the prerequisite to their capacity to make the most of their potential.

Officers and employees work together to implement persistent safety initiatives with the goal of zero accidents, out of respect for humanity and the sanctity of life.

To raise the awareness, every year, Toray Group creates a group-wide safety slogan. In 2023, the aim was for each and every employee of Toray Group to come together as a concerted group to raise awareness of safety as the top priority and to ensure that basic safety rules and work fundamentals are thoroughly followed on work sites by upholding the Group slogan—Top Priority is Safety, Pursue “Zero Accidents,” Following the rules and thoroughness in fundamentals. By keeping the same fiscal 2023 slogan for fiscal 2024, the Group is working to further enhance safety awareness and promote strict adherence to safety rules.

Due to the potentially serious impact of an accident not only within the company but on surrounding communities, the Group acts with strong determination to prevent accidents such as fires and explosions, making accident prevention a top priority.

Toray Group sets up safety and health committees and works to ensure the safety and health of its employees through united efforts of labor and management, based on occupational safety and health laws in the countries in which it operates. These efforts help to ensure a pleasant working environment.

2023 Safety Slogan

Top Priority is Safety, Pursue “Zero Accidents”

—Following the rules and thoroughness in fundamentals—

2023 Toray Group Safety Meeting at Toray Human Resources Development Center

2023 Toray Group Safety Meeting at Toray Human Resources Development CenterEvery year, the Toray Industries president, executive vice presidents and other officers, as well as Group company presidents and plant managers meet at the Toray Group Safety Meeting. At the meeting, safety action policies and main activities are shared to set a common course, activities at worksites are reported, and safety awards are given to raise awareness of safety and foster horizontal development for good practices. In 2023, for the first time in four years, the meeting was held in person at the Toray Human Resources Development Center as the main venue. To allow even greater participation, the event was carried out using a hybrid format, allowing various Toray plants and group companies worldwide to join in online.

Furthermore, the Safety Summit, on-site safety lecture by Toray Industries directors, and other events are held on a national and regional basis, and at each group company and plant of the Group. These efforts promote a common awareness of the Toray Group safety slogan, policies, and main activities, enabling centralized management of safety activities across the Group.

In addition, representatives of the senior management and labor unions at Toray Industries hold regular meetings. They discuss issues related to safety and health, establish a shared understanding of the issues, and engage in forward-looking discussions to improve the workplace environment. Safety and health committee meetings are also held at each business site (plant) every month, with the participation of the site head, managers and labor union representatives concerned. They share safety activity policies and give and receive instructions to prevent recurrence of occupational accidents that have recently occurred in Toray Group, while also reporting and discussing other matters related to occupational safety and health.

Opening of the 2023 Health and Safety Conference (slogan chanting) (Toray Construction Co., Ltd.)

Opening of the 2023 Health and Safety Conference (slogan chanting) (Toray Construction Co., Ltd.)![Keynote Address by the general manager of the Environment & Safety Department (Toray Industries) at the East and North China Safety Meeting [Toray Industries (China) Co., Ltd.]](images/prevention_p3.jpg) Keynote Address by the general manager of the Environment & Safety Department (Toray Industries) at the East and North China Safety Meeting [Toray Industries (China) Co., Ltd.]

Keynote Address by the general manager of the Environment & Safety Department (Toray Industries) at the East and North China Safety Meeting [Toray Industries (China) Co., Ltd.]

Examples of Workplace Initiatives in Fiscal 2023

Two of the Group Companies Receiving Safety Awards

Toray Engineering Co., Ltd. has been recognized for its ongoing activities in providing safe and secure equipment and facilities through the establishment of a safety equipment supply system. The company received an encouragement prize at the 8th Mukaidono Safety Award. This program was established in 2015 in honor of Masao Mukaidono, Professor Emeritus at Meiji University, who is a leader in product and labor safety in Japan. Awards are presented to individuals and organizations that have made significant contributions to maintaining, improving, advancing and spreading safety practices within various industrial sectors.

As an outstanding workplace for safety and health in fiscal 2023, Toray Coms Gifu Co., Ltd. has been honored with an excellence award from the Gifu Labor Bureau under the Ministry of Health, Labour and Welfare. While recognizing the company for its proactive efforts in ensuring the safety and health of workers through labor-management cooperation, this award also commends the company’s health and safety standards, making it a model for other companies.

Professor Masao Mukaidono (left) and the general manager of the Product Safety and Quality Assurance Management Department (right) (Toray Engineering Co., Ltd.)

Professor Masao Mukaidono (left) and the general manager of the Product Safety and Quality Assurance Management Department (right) (Toray Engineering Co., Ltd.) President holding the award certificate together with the general manager of the Operations Division (Toray Coms Gifu Co., Ltd.)

President holding the award certificate together with the general manager of the Operations Division (Toray Coms Gifu Co., Ltd.)

Safety Meeting with the Central Japan Railway Company (JR Central) (Toray Industries, Inc. Gifu Plant)

Safety meeting

Safety meetingOn January 26, 2024, the Toray Industries Gifu Plant hosted a safety meeting with members of the Transportation Safety Department of Central Japan Railway Company (JR Central). The meeting included a presentation on the plant’s safety activities, a tour of the film production department, and an exchange of opinions. The Gifu Plant representatives outlined their safety activities that began following a major accident in 1989, explained how the activities have evolved, and provided an overview of their current safety initiatives and approaches. JR Central shared their efforts to ensure safe and reliable transportation based on their Safety Charter and discussed their safety activities focused on the three pillars of people, systems, and equipment. The JR Central team commended the Gifu Plant for its high level of safety awareness, its proactive efforts to cultivate a safety-focused culture, and the comprehensive onsite safety measures it has implemented.

Activity Report Meeting After a Workplace Accident and a Safety Conference (Toray Industries, Inc. Mishima Plant)

Final report meeting for voluntary special safety activities

Final report meeting for voluntary special safety activitiesIn March 2024, the Mishima Plant held a final report meeting concerning voluntary special safety activities implemented in response to a workplace accident that occurred at the plant in December 2023. Approximately 150 people, including online participants, attended the meeting. Four representative departments, including the film production section, the unit where the accident occurred, reported on their activity results. The plant also holds the Toray Mishima Plant General Safety Conference every year. It was recently held on December 18, 2023, at the Toray Human Resources Development Center. There were approximately 120 participants, including personnel from about 60 onsite group companies and offsite partner companies, as well as online attendees. The conference included reports on the safety performance of each department and company, recognition of outstanding cases, and presentations on safety initiatives by key departments and partner companies.

Safety Audits at Group Companies Outside Japan (Toray Composite Materials America, Inc.)

Onsite inspection

Onsite inspectionTo conduct a safety audit, an executive vice president of Toray Industries paid a three-day visit to the Decatur and Spartanburg Plants of Toray Composite Materials America, March 20-22, 2024. During the on-site inspections, the executive vice president offered guidance on enhancing safety, while emphasizing the need for work process automation and adherence to the 3S and 5S safety fundamentals.

Toray Group Safety Record

Number of major accidents

- ■Reporting scope

- Toray Group

- ■Target in 2023 (calendar year)

- 0

Result in 2023

1

Number of fire and explosion accidents

- ■Reporting scope

- Toray Group

- ■Target in 2023 (calendar year)

- 0

Result in 2023

1

Achievement for world's best standard for safety management

(not exceeding 0.05 frequency rate for occupational accidents resulting in lost work time)

- ■Reporting scope

- Toray Group

- ■Target in 2023 (calendar year)

- No more than 0.05

Result in 2023

0.40

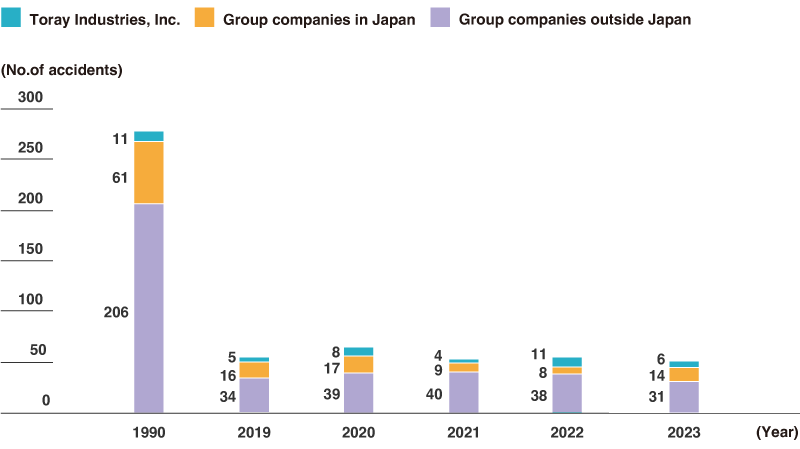

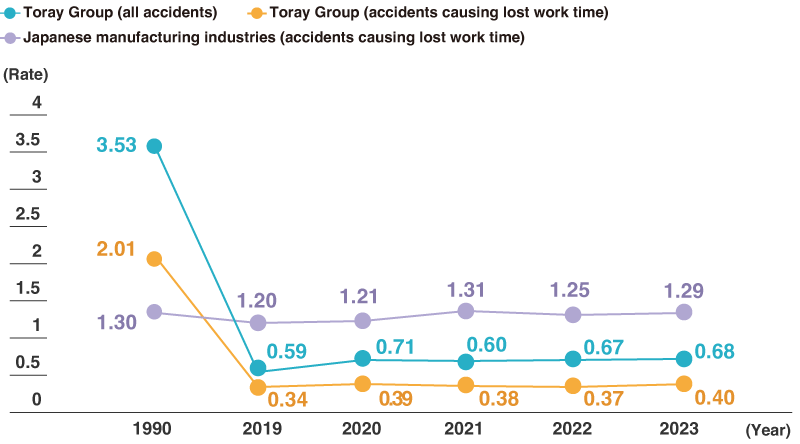

Toray Industries has collected data on all occupational accidents since 1980, and for Toray Group since 1990. Both the number of occupational accidents and frequency of occupational accidents resulting in lost work time have declined, compared with when the data was first collected. The frequency rate for occupational accidents resulting in lost work time for Toray Group overall in 2023 was 0.40. Although this is a positive result compared with that of Japan’s manufacturing industry (1.29), it fell far short of the Group target of achieving the world’s highest standard of safety management of 0.05 or lower. One reason for this is that group companies had many accidents resulting in lost work time. Accordingly, the Group is working to strengthen safety management at those group companies with support and guidance from Toray’s main plant in Japan.

Toray Group will continue to identify the root cause of each accident to prevent reoccurrence, and avoid similar accidents based on the lessons learned in these accidents. Additionally, the Group will raise employee awareness of the need to practice safety first at all times.

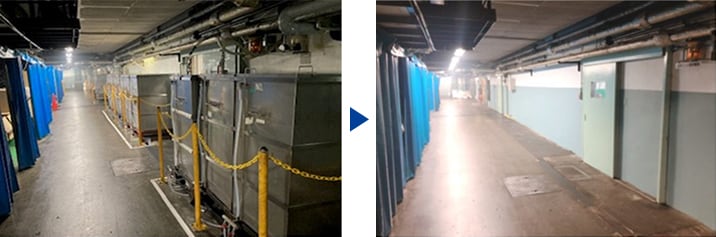

Toray Group believes that safety activities depend upon a repetition of simple things. It is important to commit to the basics of safety and for everyone, without exception, to practice the basics at all times. The first step is to work on the comprehensive implementation of the 5S’s—seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize) and shitsuke (sustain). Through these activities, all employees learn to adopt seiketsu and shitsuke. Seiketsu fosters employees' motivation to keep the workplace standardized and clean, and shitsuke raises employees’ awareness to adhere to the rules. They also take the time to reconsider movement pathways to make work safer. Managers repeatedly go around worksites, praising good behavior in an effort to raise workplace morale.

Next, the Group works to eliminate accidents in routine activities. Managers strive to maintain a sense of alertness in the workplace by continually reminding people to act with safety first, considering what the consequences (accidents) could be under any and all circumstances. In addition, if an occupational accidents does occur, an accident report is sent out to the entire Toray Group. In an effort to eliminate similar accidents, the unit heads and unit chiefs of each workplace take a leading role in discussing the report with workplace team members, imagining the cause of the accident as a specific danger in their own workplace, in order to raise everyone’s safety awareness and ensure commitment to the basics.

In fiscal 2023, a commuter bus accident occurred at a Group company outside Japan, resulting in multiple employee injuries. The accident was treated as a serious incident in accordance with company regulations. As part of its response measures, the company has implemented strict protocols for driver health management and is ensuring that employees wear seat belts while on board.

While there were no fire or explosion accidents at Toray Industries or Group companies in Japan in 2023, there was one such accident at a Group company overseas. The incident involved an explosion at a volatile organic compound (VOC) processing facility. In response, the company concerned revised its assessment criteria for equipment modifications to ensure compliance with Toray Industries’ disaster prevention technical standards in the event of emergencies. In an effort to eliminate similar fire-related accidents, the Group has a system to enable Group companies to rapidly share critical information on fire-related accidents. The Group uses knowledge gained from previous accidents to adopt effective fire prevention strategies and implement unified accident prevention management standards.

Example of work made safer by improving movement pathways by removing unnecessary items

- 1 Data for Japan includes non-regular employees (part-time employees, contract employees, casual part-timers, and dispatched workers). Data from outside of Japan does not include temporary staff.

- 2 Occupational accident frequency rate: The number of fatalities and injuries at worksites per one million cumulative working hours.

Identifying Danger (Hazards), Evaluating Risk, and Accident Surveys

1. Identifying danger (hazards) and evaluating risk

Toray Group has a system whereby employees report any potential risks in the workplace to managers and the managers provide feedback on countermeasures and improvements. Before starting work, hazard prediction information, near miss reports, and safety proposals are shared with employees to confirm and mitigate risks.

Company inspectors also carry out audits to review the system for preventing occupational accidents and the status of the implementation of countermeasures. If there are any problems, the inspectors give instructions for improvements.

2. Accident investigation

In the event of an occupational accident, the emergency response review meeting and the countermeasure meeting are convened to clarify the chain of events leading up to the accident, identify the cause, and decide on and execute countermeasures. In addition, information about the accident is shared throughout the Group and measures taken to prevent a reoccurrence.

3. Prioritized risk reduction activities

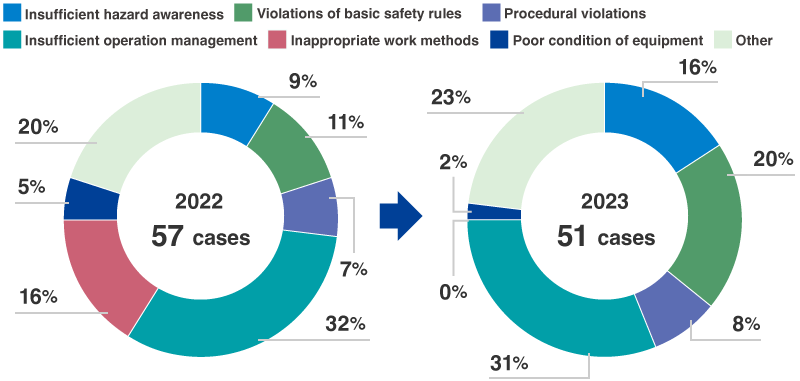

Among the main causes of workplace accidents within Toray Group in 2022, 11% were due to violations of basic safety rules that everyone must follow, while 7% were attributed to procedural violations. These are situations where tasks were not performed according to the standard operating procedures, often due to carelessness.

In 2023, the Group focused on eliminating accidents caused by both basic safety rule and procedural violations. Initiatives were launched to eliminate ambiguous rules, and provide manager-led training on rule adherence. Rule awareness activities were also carried out to help employees understand what can happen if rules are not followed and the purpose of the rules. In 2023, 20% of accidents were due to violations of basic safety rules and 8% were due to procedural violations. As a result of the 2023 activities, however, there were no accidents caused by basic safety rule or procedural violations in the first half of 2024, indicating that the initiatives have been effective.

In 2024, the Group will continue to analyze the accidents that occurred in 2023 from various perspectives and promote improvement activities aimed at eliminating accidents, by utilizing the plan-do-check-act (PDCA) cycle method.

Enhancing Safety and Accident-Prevention Training

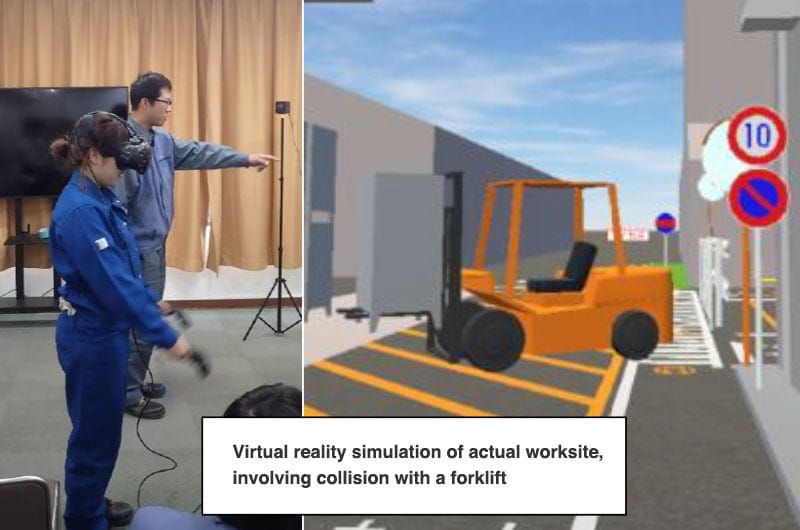

As part of their safety and accident prevention training, Toray Group companies and plants provide workshops and hands-on simulations to sensitize employees to dangers and hazards. Safety simulators enable workers to experience the dangers of electrocution, residual pressure, and getting caught in rollers. Virtual reality (VR) technology is also used to realistically simulate accidents at worksites. In the area of accident prevention, the Group conducts simulation training to teach employees about the risk of fires and explosions, and provides training on the fundamentals of accident prevention.

Additionally, the Group publishes on familiar topics regarding safety and accident prevention in its in-house magazine, People, in an effort to spread understanding of the fundamentals of accident prevention.

Simulation training at Mishima Plant (Toray Industries, Inc.)

Simulation training at Mishima Plant (Toray Industries, Inc.) Simulation training at Nagoya Plant (Toray Industries, Inc.)

Simulation training at Nagoya Plant (Toray Industries, Inc.)

Demonstrating the danger of fires and explosions at Gifu Plant (Toray Industries, Inc.)

Demonstrating the danger of fires and explosions at Gifu Plant (Toray Industries, Inc.)

Implementing Safety Management Together with Subcontractors

Toray Industries implements uniform safety activities for its own work as well as subcontracted work that is subcontracted to on-site Toray affiliates3 and Group companies. Monthly occupational health and safety committees and regular safety and liaison meetings are used to discuss the implementation status of safety activities and enhance communication with subcontractors, to ensure that all parties are aligned in the implementation of safety activities. Employees conduct on-site monitoring of operations in practice such as those involving forklifts and sharp-edged objects and use the results to generate recommendations for necessary improvements that enhance safety and ease of work. Subcontractors also submit their requests for work and equipment improvements, to increase physical safety.

- 3 Toray affiliates: Toray Industries’ subsidiaries that provide ancillary services for plant operations

On-site monitoring of actual work (Toray Coms Nagoya Co., Ltd.)

On-site monitoring of actual work (Toray Coms Nagoya Co., Ltd.) Onsite forklift safety training session attended by 21 participants from seven group and partner companies involved in forklift operations (Toray Industries Inc. Ehime Plant)

Onsite forklift safety training session attended by 21 participants from seven group and partner companies involved in forklift operations (Toray Industries Inc. Ehime Plant)

Safety Management Implemented by Subcontractors

Safety meeting at Ishikawa Plant (Toray Industries, Inc.)

Safety meeting at Ishikawa Plant (Toray Industries, Inc.)Toray Group recognizes its duty to ensure the safety of the many subcontractors working at its sites. As colleagues working in the same workplace, subcontractors are made aware of, and expected to comply with, Toray Group rules. Subcontractors also participate in monthly meetings of occupational safety and health committees. Regular safety and liaison meetings are conducted to gain input from subcontractors and are used to communicate the Group's policies and to make sure all measures are implemented. In addition, the Group educates subcontractors who work on a short-term basis about Toray Group rules before work commences and manages safety thoroughly. At plants, Toray and subcontractors work together on safety initiatives, including safety posters, slogan contests and safety suggestions.

Preparing for Accidents through Fire-Prevention Drills

All companies and plants in Toray Group are making efforts to improve their accident-prevention capabilities by carrying out fire-fighting drills specifically intended for fires and explosions. These drills include practice using water hoses, rescuing the injured, responding to a chemical leak, and giving emergency notification to authorities and local residents.

Since 2012, Group companies and plants have been conducting annual drills on setting up a company-wide emergency headquarters in response to a large-scale earthquake. The drills also involve checking on employees and monitoring facilities damage and supply chains. In 2023, the Group conducted a training exercise based on the scenario of not being able to set up the company-wide emergency headquarters at the Tokyo Head Office. This scenario presumed a catastrophic earthquake comparable to the Great East Japan Earthquake together with a major earthquake centered in the Tokyo metropolitan area. The exercise involved setting up the company-wide emergency headquarters in the Kansai region (Osaka Head Office, Shiga Plant) to manage the situation. In addition to conducting drills for the initial response to a large-scale earthquake, Group plants in seaside locations conduct drills of the evacuations that would be needed if a tsunami were triggered by a large-scale earthquake.

Fire prevention training (Maruichi Fiber Co., Ltd.)

Fire prevention training (Maruichi Fiber Co., Ltd.) Firefighting training (Ogaki Fuso Spinning Co., Ltd.)

Firefighting training (Ogaki Fuso Spinning Co., Ltd.)

Disaster prevention training at the Aichi Prefecture Petrochemical Complex (Toray Industries, Inc. Tokai Plant)

Disaster prevention training at the Aichi Prefecture Petrochemical Complex (Toray Industries, Inc. Tokai Plant) Fire hose deployment training conducted by the division first response firefighting team (Toray Industries, Inc. Okazaki Plant)

Fire hose deployment training conducted by the division first response firefighting team (Toray Industries, Inc. Okazaki Plant)

Initiatives for Improving Fire-Prevention Capabilities

Toray Group is further enhancing its disaster prevention capabilities. In 2023, as part of the regularly held activities to strengthen fire prevention for the Fire Prevention Project Part Ⅱ, Toray Group in Japan conducted certification training for FP4 key persons, who play a pivotal role on the frontlines by promoting accident prevention inspections and measures. As a result, a total of 223 individuals were newly certified. Toray Group’s internal accident prevention experts provided support and guidance in identifying the root cause and taking countermeasures to prevent reoccurrence of those fire accidents and near misses for which the experts decided onsite audits and investigations were necessary.

The Group’s earthquake measures seek to mitigate damage, while placing utmost priority on saving the lives of employees and preventing impacts on local communities. The Toray Group Business Continuity Plan (BCP) for a Large-Scale Earthquake outlines the emergency response to an earthquake and subsequent activities to maintain and restore business operations, as well as the Group’s duties and normal readiness. In particular, for critical products, the Group develops BCPs that encompass supply chains and continually works to reduce risks.

- 4 FP : Fire Prevention

Examples of Workplace Initiatives in Fiscal 2023

First Aid and CPR Training

With the support of the Japanese Red Cross Medical Center and local fire departments, Toray Group conducts life-saving training using CPR mannequins and AEDs.

CPR training (Toray Industries Inc. Seta Plant)

CPR training (Toray Industries Inc. Seta Plant)![Employees listening intently to the experiences of a paramedic [Toray Industries Inc. Basic Research Center (Kamakura)]](images/prevention_p21.jpg) Employees listening intently to the experiences of a paramedic [Toray Industries Inc. Basic Research Center (Kamakura)]

Employees listening intently to the experiences of a paramedic [Toray Industries Inc. Basic Research Center (Kamakura)]

Distribution Safety Initiatives

Toray Industries is working to ensure safe distribution in its operations. In an effort to manage safety when transporting hazardous substances, the Company concludes security agreements with certain customers, raw material manufacturers, and shipping companies to designate their specific safety responsibilities and roles with regards to safety.

Initiatives to Reduce Health Effects of Chemical Substances on Employees

In consideration of the health risks to the Company’s employees, including contracted, part-time, and dispatched employees, Toray Group is implementing the following initiatives for the handling of chemical substances.

- Study the actual handling of chemical substances

Toray Group collects annual data on the volume of chemical substances handled by offices and plants of Group companies and volume in their possession. Furthermore, the Group clearly indicates the danger of mutagenicity for each chemical substance as stipulated in the Industrial Safety and Health Act, and discloses the risks. - Implement chemical substance risk assessments

Toray Group implements risk assessments using a variety of tools, which include working environment measurements for the chemical substances that it handles, ECETIOC Targeted Risk Assessment (TRA), CREATE-SIMPLE assessments, and control banding. The risk assessment results are used to protect the health of employees by implementing comprehensive measures to prevent worker exposure to organic solvents and dust where it is required. - Conduct follow-up through internal audits

Toray Group conducts an annual safety, health, accident prevention, and environmental audit, to objectively evaluate the methods for handling chemical substances and working conditions. The audit is used to identify any oversights or unattended issues and implement necessary improvements. - Other

Toray Group endeavors to maintain and improve working conditions by conducting working environment measurements and on-site monitoring of actual work in accordance with the risk level of handled substances. It also conducts medical checkups to continually follow-up on the health status of employees. To prevent health issues among workers, the Group conducts training on the dangerousness of handled chemicals, and prepares and keeps records of the on-site monitoring of actual work.

Health Effects and Response to Asbestos

Toray Group has manufactured and imported building materials containing asbestos in the past. In addition, certain buildings and facilities were constructed using such materials and thermal insulation containing asbestos. Starting in 2005, when asbestos-related health hazards became a social concern in Japan, Toray took action to address the issue of its own asbestos-containing facilities. The health program offers medical examinations to current and former employees who handled even small amounts of asbestos and wish to undergo an examination. Toray Group is working in good faith with individuals diagnosed with asbestos-related health issues by assisting with their applications for workers' compensation and providing an ongoing program of medical examinations. The Group has not been contacted about health issues by residents living near affected plants.

The cumulative health impacts on former and current Toray Group employees as of March 31, 2024 are as follows.

Certified occupational accidents arising from handling asbestos (Toray Group): 130 (111)*

Certified health victims based on Japan's Act on Asbestos Health Damage Relief (Toray Group): 8 (8)*

Medical examination recipients involving asbestos (Toray Group): 4,041

- * Figures in parentheses refer to fatalities as of March 2024.

Click here for the main initiatives for CSR Guideline 3, “Safety, Accident Prevention, and Environmental Preservation” in CSR Roadmap 2025.