- HOME

- Research and Development

- R&D Organization

- Research Laboratories

- Global Environment Research Laboratories

Global Environment Research Laboratories

The Global Environment Research Laboratories was first launched in 1991 as the Global Environment Research Laboratory, and then re-established as the Laboratories in 2002. The laboratories develops and commercializes all types of membrane products in the water treatment field, based on the foundation of Toray's organic synthesis technology, polymer technology and nano-processing technology.

The Global Environment Research Laboratories carries out research which meets customer's requirements with polymeric membrane technology utilizing polymer chemistry. Up to now, we have created all types of separation membranes, such as reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF) and microfiltration (MF) membranes, used for water treatment including seawater desalination. Recently, we have also focused on R&D on membranes for new fields such as resources, energy, foods, and bio-applications.

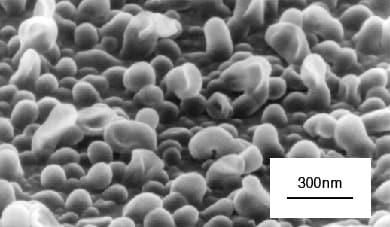

Surface of high-performance RO membranes synthesized with precise interface polymerization

Surface of high-performance RO membranes synthesized with precise interface polymerization*Winner of the 2014 Chemistry Technology Awards of Chemical Society of Japan

RO membranes

These membranes simultaneously achieve enhanced boron removal and high water permeability by using unique technology to control pore size and fine membrane structures at the subnanometer level. We have also engaged in extensive analysis of the separation functional layer of RO membranes, and quantitatively clarified the protuberance structure, pores, and water channel structure for the first time in the world. In addition, by using unique interfacial polymerization and surface control technology, we have successfully developed highly functional RO membranes with high water permeability, removal performance, and fouling resistance.

UF and MF membranes

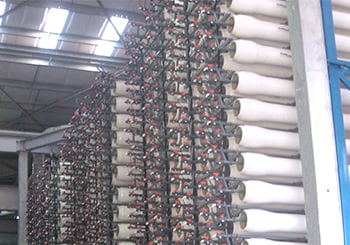

We have developed PVDF hollow fiber membranes featuring both toughness and a precise pore structure due to our unique thermally induced phase separation method. These membranes have been recognized for their high durability and separation performance in applications such as production of drinking water and industrial water. Recently, we have also successfully achieved finer fibers through the pursuit of greater toughness, and created membrane modules with world-class surface area. PVDF submerged MF membranes for membrane bioreactors possess excellent resistance to sludge clogging and high water permeability due to reduced surface pore size and an increased number of pores.

R&D in new fields

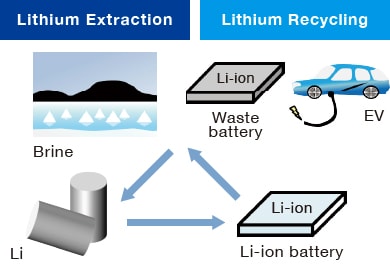

We are conducting R&D on membranes for use in new fields, based on water treatment and separation membrane technology cultivated over many years. For example, for the realization of a hydrogen-based society, we are conducting research on polymeric membranes for high-efficiency separation of hydrogen, and research on new NF membranes to recover lithium, for which demand is expected to grow in the future.

PVDF hollow fiber membranes featuring both toughness and a precise pore structure due to our unique thermally induced phase separation method

Hamma Seawater Desalination Plant, first in the 100,000 m3/day class in Africa, using Toray's RO membrane elements (Algeria)

※The membrane elements won the Monodzukuri Nippon Grand Award, Special Prize in 2009

Photo:GE Water & Process Technologies

Global research and development

Our global R&D efforts include region-specific customer demonstrations based on water quality analysis. This work is being done in collaboration with the Toray Advanced Materials Research Laboratories (China) Co., Ltd., and the Research Center of Toray Industries (India) Private Limited etc.

R&D for lithium high-efficiency separation membrane for Sustainable Development Goals

Membrane element and pressure vessel for hydrogen gas separation

Milestones in Toray R&D

| 1981 | Commenced production of reverse osmosis membrane. |

|---|---|

| 1991 | Global Environment Research Laboratory opened in Shiga. |

| 1998 | Commenced production of PAN hollow fiber ultrafiltration membrane. |

| 2002 | Changed name to Global Environment Research Laboratories. |

| 2005 | Established production technology of PVDF hollow fiber membrane. Established production technology of PVDF membrane for MBR. |

| 2015 | Created innovative reverse osmosis (RO) membrane. |

| 2018 | Created polymeric membrane for hydrogen purification. |

| 2019 | Created ultra-high water permeability nanofiltration (NF) membrane. |