- HOME

- Research and Development

- R&D Organization

- Research Laboratories

- Fibers & Textiles Research Laboratories

Fibers & Textiles Research Laboratories

The year following Toray's foundation, a research division for viscose rayon was established. In 1969, the Fibers & Textiles Research Laboratories was launched, integrating the fiber research laboratories that had previously been scattered throughout Japan. Since then, the laboratories has been conducting a wide range of research on fibers and textiles including polymer design, fiber spinning technologies, and textile processing technologies to help bring new fibers and textiles to market.

The Fibers and Textiles Research Laboratories has yielded various new products, as well as carbon fibers, artificial kidneys and other fundamental technologies to spearhead new business. At present, the laboratories is enhancing fundamental technologies used in new products for apparel. It is also creating environmentally-friendly fiber materials, and conducting research to achieve higher functionality of fibers to pursue the limits of what is possible.

ULTRASUEDE™

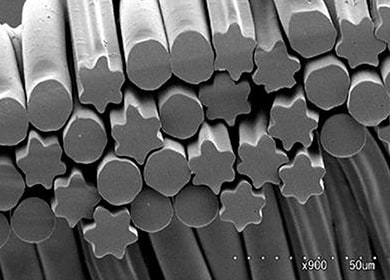

ULTRASUEDE™ is a suede-texture artificial leather using micro-fibers produced through the “islands-in-the-sea” conjugate spinning process.

Due to its outstanding quality and functionality, it is used in a variety of fields including the fashion industry, and as a material for interiors and precision equipment.

Kinari™

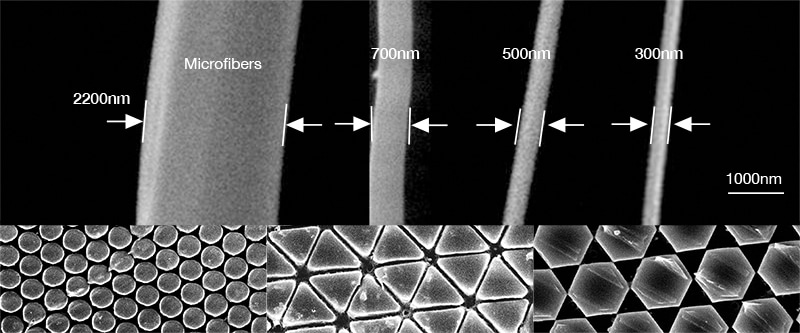

Toray's research, which has produced a variety of SILLOOK™ series, and NANODESIGN™, which can design cross-sections on a nanoscale, have created polyester textile with real silk-like texture, by designing the fibers and textile cross-sections.

※Winner of the 2019 Senken Gosen Award, Material Division

※Winner of the 2019 Technology Award of The Society of Fiber Science and Technology

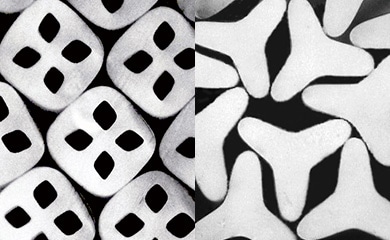

Cross-section of textile made from cationic dyeable polyester

Cross-section of textile made from cationic dyeable polyesterNew products used in apparel

The laboratories is undertaking polymer research, including the improvement of polyester.

One of the developed products, cationic dyeable polyester, used in HEATTECH™,is widely used for apparel, arranged by Toray’s unique technologies of fiber processing.

*HEATTECH™ is a registered trademark of FAST RETAILING CO., LTD.

Environmentally-friendly fiber materials

The laboratories is working to create environmentally-friendly fiber materials, including ECODEAR™ Polylactic Acid (PLA) fiber, Primeflex™ 3GT fiber made of raw materials derived from biomass, and FORESSE™, the world's first cellulose-based melt-spun fiber.

FORESSE™

FORESSE™ is a world’s first thermoplastic cellulose fiber which doesn’t require harmful chemicals used in the production of conventional cellulosic fibers.

This is also a breakthrough that opens the door to the manufacture of modified cross-section filaments, ultra-fine fibers and other fiber types that conventionally impossible in the past.

※Winner of the 2007 Senken Gosen Award, Grand Prix and Technical Division

High-performance fibers

The laboratories is also focusing on the research about Super Fibers, like Polyphenylene Sulfide Fiber, Liquid Crystal Polymer Fiber, and so on. It also succeeded in creating world-class polyester conductive fiber.

In pursuit of the limits of textile technology

The laboratories is conducting research that involves enhancing functionality by controlling the molecular orientation and crystal structure of fibers, as well as research on nanofibers that push the limit of fineness. In this area, it has successfully developed NANODESIGN™, an innovative spinning technology. With this technology, it has successfully created the world’s first nanofibers with modified cross-sectional shapes, and Kinari™, a fabric with a silky new feel.

World’s first nanofibers with modified cross section via NANODESIGN™

※Winner of 2018 The Award for High Technology Pioneering Originality, Minister of Economy, Trade and Industry Prize

Milestones in Toray R&D

| 1927 | Research Division for viscose rayon was established. |

|---|---|

| 1941 | Succeeded in mobilizing original technology to synthesize and spin Nylon-6 fiber. |

| 1964 | Commenced production of SILLOOK™ silk-texture polyester fiber. |

| 1969 | Fibers & Textiles Research Laboratories was established. |

| 1970 | Commenced production of ULTRASUEDE™ suede-texture artificial leather. |

| 1987 | Commenced production of TORAYSEE™ high-performance multipurpose wiping cloth. |

| 2002 | Commenced production of composite fiber using 3GT polymer. |

| 2005 | Created FORESSE™, the world's first cellulose-based fiber employing the melt spinning method. |

| 2014 | Developed NANODESIGN™ innovative composite spinning technology. |

| 2019 | Developed Kinari™, fabric with a silky new feel. |