- HOME

- Research and Development

- R&D Organization

- Research Laboratories

- Chemicals Research Laboratories

Chemicals Research Laboratories

Established by combining the Plastics Research Laboratory and Specialty Chemicals Research Laboratory in 1999, the Chemicals Research Laboratories set to work as laboratories for creating a wide variety of chemical products, ranging from specialty chemicals to polymers. By exploiting polymer science, synthetic chemistry technology, catalyst technology, and nanotechnology, the laboratories conducts research on advanced materials in the fields of mobility and information and communications.

The Chemicals Research Laboratories acts as the foundation of Toray's R&D on chemical and basic polymer products. The laboratories is working in areas such as new polymer development, improved function, and high-level structure control, and actively using digital technology.

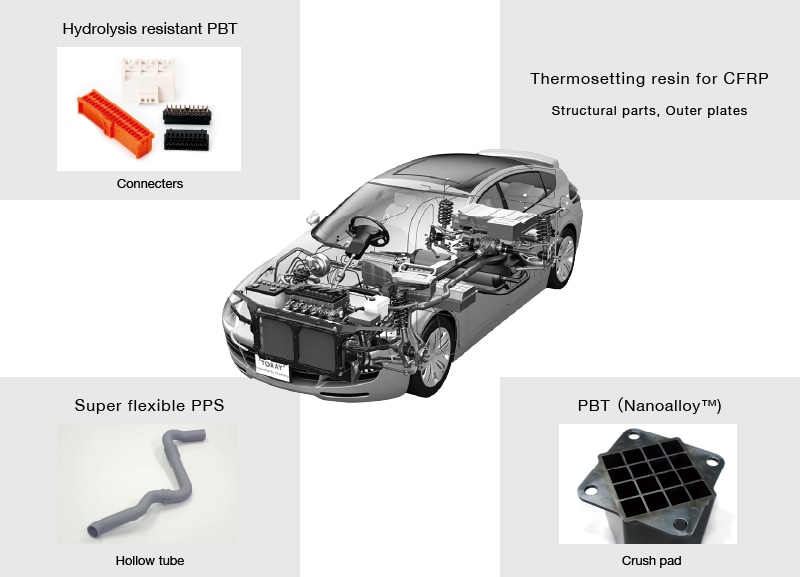

Next-generation mobility materials

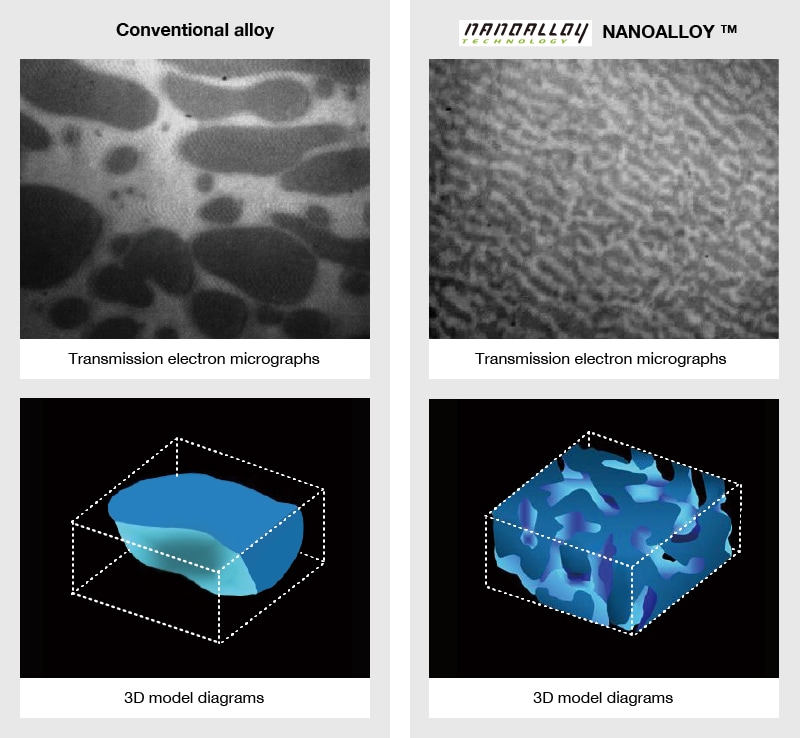

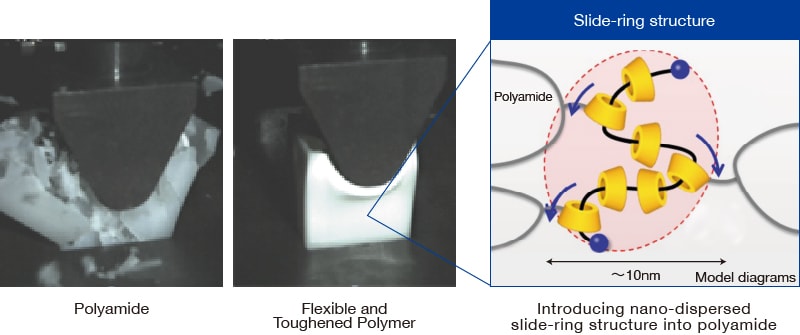

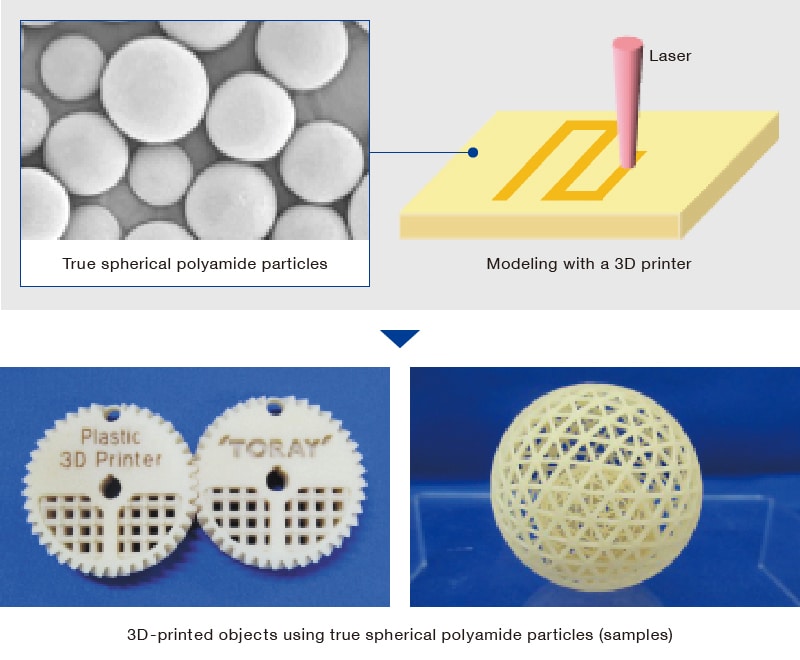

The mobility field is undergoing great changes, and the materials used in the field need to have unprecedented new functions. At the Chemicals Research Laboratories, we are researching innovative materials with an eye toward next-generation mobility, in areas such as improving functionality of thermosetting polymers for CFRP and engineering plastics. We have recently participated in a national project, and successfully created new technologies and materials, such as flexible and toughened polymer with dramatically improved impact performance and fatigue resistance, and super flexible polyphenylene sulfide based on Toray's unique NANOALLOY™ nano-structure control technology. Furthermore, the laboratories is conducting research targeting key applications and techniques for next-generation mobility, such as innovative LiB materials for xEVs, hydrogen tank materials for FCVs, and microparticles for printing 3D parts.

Sustainable materials

The Chemicals Research Laboratories is engaged in research on degradable polymers and recycling technology, and tackling the challenges of solving social issues from a comprehensive environmental perspective that takes into account not only curbing CO2 emissions during product use, but also reducing environmental impact after use.

Innovative materials for automobiles and applications

NANOALLOY™

Precise control of polymers on the nano-order with our unique alloy technology

Flexible and Toughened Polymer

Flexible and Toughened polymer that absorbs stress when subjected to impact

Polyamide particles for 3D printers

Milestones in Toray R&D

| 1951 | Established Synthetic Fiber Laboratory (later Specialty Chemicals Research Laboratory). |

|---|---|

| 1959 | Established Plastics Engineering Research Laboratory (later Plastics Research Laboratory). |

| 1962 | Commenced production of Caprolactam (Photo-Nitrosation of Cyclohexane method). |

| 1975 | Commenced production of PBT resin. |

| 1997 | Commenced production of SIVERAS™ liquid-crystal polyester resin. |

| 1999 | Established Chemicals Research Laboratories. |

| 2001 | Created NANOALLOY™. |

| 2007 | Developed shock absorbing polymer. |

| 2016 | Developed flexible and tough polymer. |

| 2019 | Developed PPS resin with world-class flexibility. |

| 2020 | Developed technology for true spherical polyamide particles. |