Notes:

- This product does not employ seam tape. The water pressure resistance of the seams is not 1,000mm H2O.

- Users are responsible for selecting dioxin control protective clothing that matches conditions at waste treatment facilities.

LIVMOA™4000 performance details

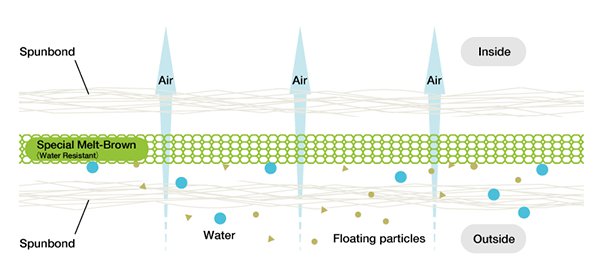

Structure

The nonwoven fabric comprises a dense, water-resistant polypropylene meltblown layer sandwiched by durable spunbond polypropylene layers.

Functionality and applications

The clothing is dustproof and water-resistant, making it suitable for wearing at waste disposal sites and in regular factory equipment repairs. It is also breathable, helping to reduce dampness and improve comfort.

| Product Details |

|

| LIVMOA™4000 |

|

| 1. |

Features |

|

(1) |

Proprietary SMS fabric withstands water pressure of 1,000mmH2O |

|

(2) |

Breathability reduces stuffiness inside clothing |

|

(3) |

Chemical protective clothing compliance

JIS T 8115:2015 Type 5 (sealed for protection from solid airborne particulates)

JIS T 8115:2015 Type 6 (for protection from mist) |

|

(4) |

Fabric produced at domestic Toray plant |

| 2. |

Sizes: XS, S, M, L, XL, 2XL |

| 3. |

Applications: Work that requires dust and water protection and cleaning tasks |

| 4. |

Launch timing: January 2021 |

| 5. |

Distributor: Sunrich Mode Inc.

(available from tool, uniform, health and sanitary product, and other suppliers) |

| 6. |

Retail price: Discretionary |

|

|

|

|

| Updated LIVMOA™CL clothing |

|

| 1. |

Features |

|

(1) |

Minimal dust generation |

|

(2) |

Separate pants and top for wearing ease |

|

(3) |

Highly breathable to maintain comfort |

|

(4) |

Sterilized with ethylene oxide gas to safeguard fabric performance |

|

(5) |

Designed for Japanese body sizes |

| 2. |

Sizes: XS, S, M, L, XL, 2XL |

| 3. |

Applications: Regenerative medicine, pharmaceuticals manufacturing, and other cleanrooms |

| 4. |

Launch timing: February 2021 |

| 5. |

Distributor: Waken Tech Co., Ltd. |

| 6. |

Retail price: Discretionary |

LIVMOA™ Series Lineup

| Product name |

LIVMOA™4000 |

LIVMOA™3000

LIVMOA™2000 |

LIVMOA™CL |

LIVMOA™5000 |

| Features |

Complies with JIS Type 5 and 6 standards for chemical protective clothing

Water pressure resistance: 1,000mmH2O

Breathability: 7cc/cm2・s

Fabric made in Japan |

Complies with JIS Type 5 standard for chemical protective clothing

Breathability: 96cc/cm2・s

(high breathability specification) |

Minimal dust generation

Separate top and pants

Breathable fabric

Sterilized with ethylene oxide gas |

Complies with JIS Type 4 standard for chemical protective clothing (provides protection from COVID-19)

Anti-virus barrier Class 6

Blood barrier Class 6

Moisture permeability 200g/m2/hr |

| Applications |

Waste disposal site, facilities repair, and other dusty and dirty work entailing high-pressure water usage |

General dusty and dirty work (particularly useful in hot and humid environments) |

Work in regenerative medicine, pharmaceuticals manufacturing, and other cleanrooms |

Infectious disease research and prevention work |

LIVMOA™ website:

https://www.livmoa.toray/en/