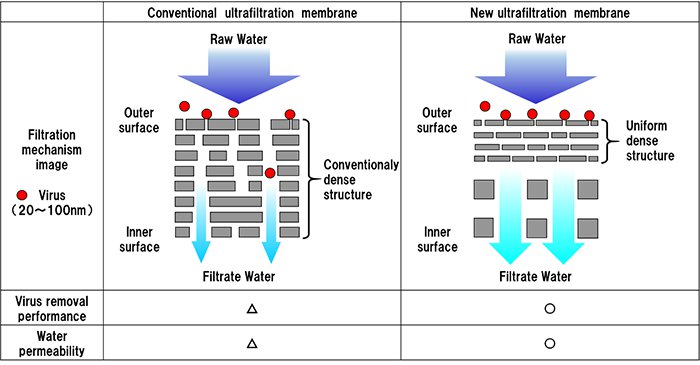

- Using phase separation control technology to create a uniformly dense structure Toray focused on minimizing coarse voids exceeding 100 nm through which viruses can easily pass. By laminating layers which have homogeneous pore size distribution, Toray create a uniform dense structure without coarse voids. This uniform dense structure made it possible to create thinner dense structure than conventional UF membrane and showed 99.99% removal of the Essherichia coli phage MS2, which has a diameter of around 27 nanometers.

- Innovative hollow fiber membrane manufacturing technology

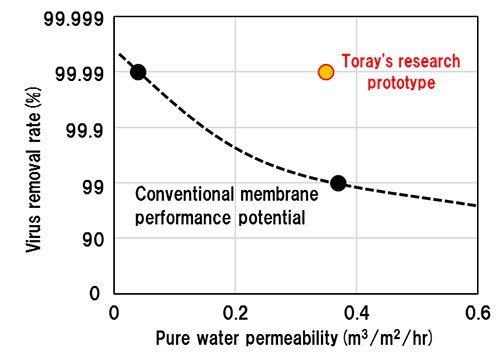

Dense structure increases resistance and impede water flow. Toray resolved that issue by using a proprietary hollow fiber membrane process technology built on the experience in water treatment and artificial kidney applications to create a thin, uniformly dense structure. Toray achieved excellent virus removal and water permeability (see figures 1 and 2) by increasing porosity in whole membrane except for the uniform dense structure, thus securing more water channels and boosting overall membrane permeability.

The Toray Group is leveraging its innovative technologies and advanced materials in its drive to provide universal access to water and air and help restore the environment in keeping with the Toray Group Sustainability Vision and Toray Vision 2030, under which it pursues sustainable and healthy growth.

In the years ahead, Toray will do much In keeping with its corporate philosophy of contributing to society by creating new value with innovative ideas, technologies, and products. It will help pave the path toward a recycling-based economy by scaling up, socially implementing, and evaluating its technology over the long term. It also looks to accelerate research into diverse applications extending from food and beverages to reusing wastewater.

References

Figure 1. Filtration mechanism

Figure 1. Filtration mechanism

Figure 2 Relationship between water permeability and virus* removal

* Essherichia coli phage MS2