Toray Industries, Inc.

Tokyo, Japan, October 28, 2021 – Toray Industries, Inc., announced today that it has developed a new version of Lumirror™, its range of biaxially oriented polyester films. It created the new film by precisely controlling the height of surface protrusions, eliminating surface defects from coarse protrusions while delivering slipperiness and other desirable handling properties.

Key among the diverse prospective applications for the new offering are functional films for semiconductors and electronic components, for which miniaturization is progressing, as well as films for their manufacturing processes. Toray has already established pilot scale technologies, and aims to initiate mass production soon.

Because of its exceptional properties, Lumirror™ is a common base material for functional films in electronic components and display applications, as well as for release, carrier, protection, and other films for the manufacturing processes of these applications. Excellent smoothness and an absence of coarse surface protrusions are essential to create high-performance films. It is also important to ensure proper handling, as greater smoothness can impair processability and slipperiness.

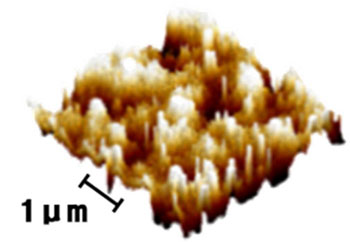

Conventional technologies thus generally enhance handling by adding lubricant particles

(see glossary) inside films or on coating layers to create surface protrusions. Toray has contributed to the evolution of smaller and thinner products for applications by controlling lubricant particle and film structure arrangements in pursuing surface control technology perfection.

Nano-order miniaturization is progressing for state-of-the-art semiconductor and electronic component applications. Even minuscule lubricant particle agglomerations can lead to coarse protrusions on film surfaces and cause nano-level coating and transfer defects. Scattered light and reduced transparency have also become issues with display applications.

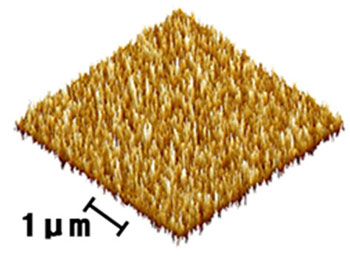

Toray resolved these issues by leveraging its unique biaxial stretching technology and special treatment to innovate a technology that forms high-density, nano-order micro-protrusions on film surfaces without using lubricant particles. This approach suppresses film surface defects from coarse protrusions while greatly enhancing smoothness and transparency. At the same time, nano-order control of micro-protrusion arrangements makes it possible to deliver processability and slipperiness in handling and maintain high quality.

The company will take advantage of these attributes in developing an array of applications for functional films for cutting-edge displays, optical devices, and battery materials, for semiconductor and electronic component applications, and for films in manufacturing processes for these applications.

Toray will keep developing advanced, highly functional materials that contribute to social progress in line with its commitment to innovating ideas, technologies, and products that deliver new value.

|

|

| Surface of Lumirror™ with nano micro-protrusion technology |

Surface of Lumirror™ with conventional technology |

Glossary

Lubricant particles prevent adhesion between films, reducing friction and allowing slide. They are also called antiblocking agents.

TORAY FILMS

https://www.films.toray/en/