Toray Industries, Inc.

Tokyo, Japan, March 30, 2022 – Toray Industries, Inc., announced today that it has won the 2021 Chemical Technology Award from the Chemical Society of Japan. This was in recognition of outstanding potential and social significance of the company’s development and commercialization of a polybutylene terephthalate and polycarbonate co-continuous high-performance nano-alloy via spinodal decomposition.

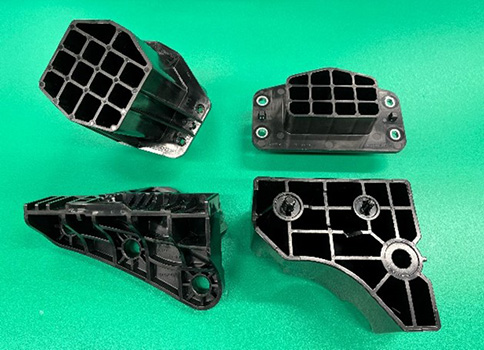

Blending polybutylene terephthalate and polycarbonate through this technology can enhance automotive safety by significantly increasing the toughness of engineering plastics through precise, nano-level alloy structure control and by absorbing energy in automobile collisions.

Enhancing occupant protection in automobiles has become an even greater priority in recent years. The general approach to date as been to install metal parts to absorb impact energy that bumpers cannot withstand. This has added considerable weight to vehicles, boosting demand for lighter polymer materials. The downside with those materials, however, is fracturing from massive energy transfers in automobile collisions. This situation has driven numerous attempts to use polymer alloys incorporating rubber to deliver superior toughness. But these alloys have been unable to handle high energy transfers in such collisions, fueling a long-awaited need for a technology that would dramatically enhance the toughness of polymeric materials.

Toray responded to that challenge by leveraging its proprietary NANOALLOY™

(see note 1) nanotechnology with a polybutylene terephthalate and polycarbonate blend. It used spinodal decomposition

(see note 2) to become the first in the world to attain precise control of the continuous nanoalloy structures of both polymers. The company’s blend can thus absorb energy equivalent to that of a collision at 36 kilometers an hour, which would damage conventional alloy materials. It now commonly serves in shock-absorbing components that enhance passenger protection.

Toray clarified the mechanism by which NANOALLOY delivers such outstanding toughness and constructed a technical system for it. The company has broadened applications for its technology to encompass polyamide and polyphenylene sulfide.

Uses have thus expanded to include synthetic strings for tennis rackets. That is because these strings maintain flexibility when subject to high-speed deformation. Another application is personal computer cases, helping protect their precision electronics in the event of drops. Toray looks to extend uses to shock-absorbing parts that protect the all-important batteries of electric vehicles.

The company will keep deepening its core technologies of synthetic organic and polymer chemistry, biotechnology, and nanotechnology in keeping with its commitment to innovating ideas, technologies, and products that deliver new value to create advanced materials and innovative technologies that contribute to social progress.

|

| Applications in shock-absorbing parts that enhance passenger safety |

|

| Researchers holding Chemical Technology Award plaque |

A Japanese-only article on Toray’s award-winning technology is available in the Chemistry and Chemical Industry journal of the Chemical Society of Japan:

Glossary

| 1. |

Toray developed NANOALLOY™, a proprietary innovative microstructure control technology that dramatically improves polymer properties by minutely dispersing multiple polymers on a nanometric scale. URL : https://www.nanoalloy.toray/en/ |

|

|

| 2. |

Spinodal decomposition is a phase separation mode when states change to an equilibrium. Microstructures formed through this mechanism often have periodic structures (it is called modulated structure). |

Toray’s Chemistry Technology Awards from Chemical Society of Japan

| 1951 |

Research on polyamide synthetic fibers and establishment of related production technology |

| 1964 |

Development of photonitrosation of cyclohexane process to manufacture -caprolactam |

| 1971 |

Disproportionation of the toluene process and pure cyclohexane production technology |

| 1973 |

Development of suede-like one-layer structured artificial leather |

| 1976 |

Establishment of production technology and industrialization of polyacrylonitrile-based carbon fiber |

| 1988 |

Development of Toray Waterless Plate system |

| 1992 |

Development of cross-linked aromatic polyamide composite reverse osmosis membrane |

| 1996 |

Development of para-based aramid film |

| 1999 |

Development of biphenyl epoxy-type molding compound for surface-mount devices |

| 2000 |

Development of endotoxin-adsorbing column for treatment of sepsis |

| 2003 |

Technology for forming barrier ribs on plasma display panel by applying photosensitive glass paste |

| 2010 |

Development and commercialization of positive photosensitive polyimide coatings by using partial esterification |

| 2013 |

Practical application of composite materials for lightweight aircraft |

| 2014 |

Development of innovative reverse osmosis membranes based on new molecular and structural design |

| 2017 |

Development of high performance CFRP with the use of epoxy resin NANOALLOY technology applying reaction-induced phase separation |

| 2019 |

Development and commercialization of high-performance positive photosensitive siloxane coatings |

| 2021 |

Development and industrialization of polybutylene terephthalate and polycarbonate co-continuous high-performance nano-alloy via spinodal decomposition |

NANOALLOY™

https://www.nanoalloy.toray/en/