- HOME

- 【From Zero to ¥240,000,000,000】How Toray built its number one share of the global carbon fiber market

【From Zero to ¥240,000,000,000】How Toray built its number one share of the global carbon fiber market

Aiming for a lighter, sturdier material──.

Toray has been researching, developing, and cultivating markets for carbon fiber for more than fifty years. At ten times the strength of steel and one-fourth the weight, carbon fiber is used in airplanes, automobiles, bicycles, fishing rods, and a host of other products.

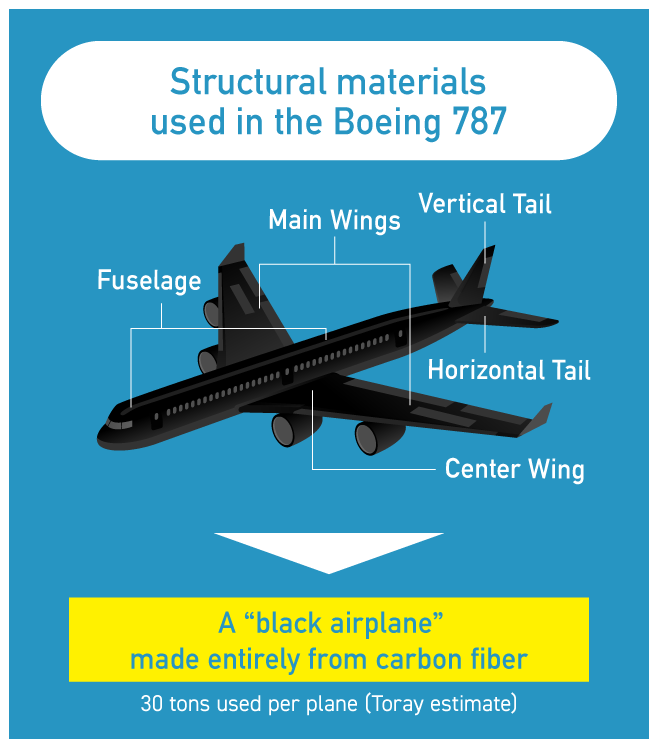

Toray has created the carbon fiber market from scratch and grown it into a business with sales approaching 240 billion yen. Carbon fiber’s popularity as a material has reached even into the wings and fuselage of so-called “black airplanes.” As Toray’s carbon fiber soars through the sky, sales are soaring, too, giving Toray the largest share of the global market.

How did Toray put a product with no existing market into practical use, carving out a market for carbon fiber? We sat down with Akihiko Kitano, a researcher at the forefront of Toray’s carbon fiber technology development, to find out the story behind black airplanes and the future of carbon fiber.

■How was Toray able to maintain focus on carbon fiber research over the years?

──What was the level of development of carbon fiber when you joined Toray?

First, let’s talk about what carbon fiber is. Carbon fiber was created in the development of the electric lightbulb. Thomas Edison and others used baked bamboo for the filament, the part that gives off light. From there, Dr. Akio Shindo, a carbon fiber researcher, developed carbon fiber into a lighter, stronger, more elastic material with an acrylic yarn-based design in 1961. Toray saw the potential of carbon fiber, and we’ve been plugging away at basic research on it since the late 1950s.

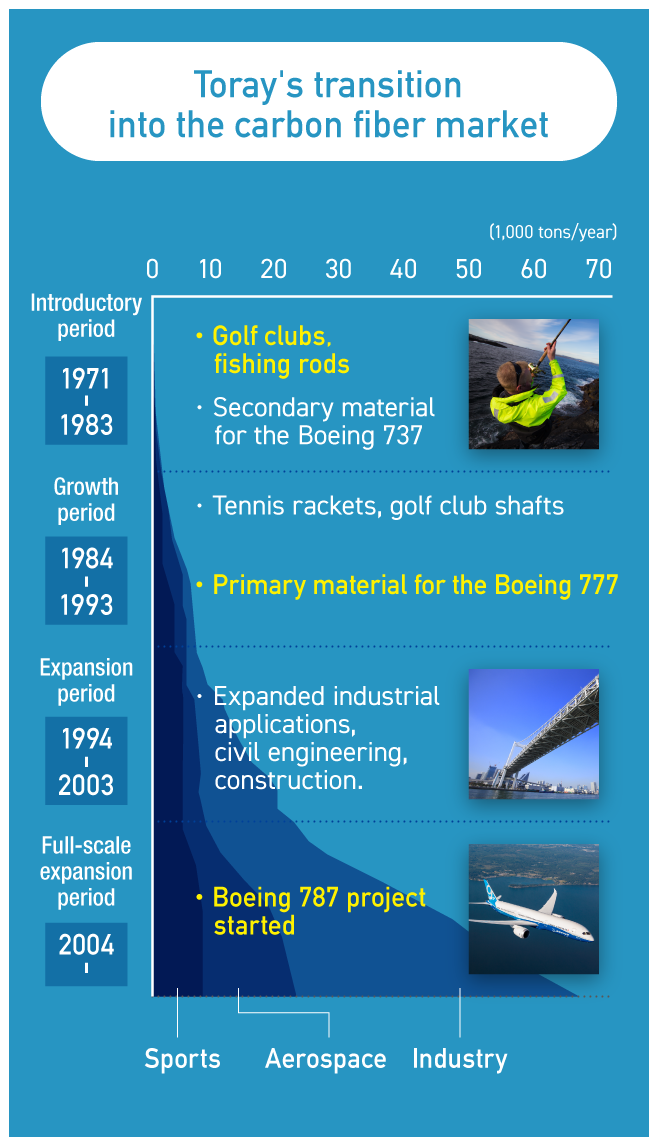

When I joined the company in 1985, Toray’s proprietary carbon fiber product “TORAYCA T300” had already been on the market for about 15 years, and we were really focused on producing a higher strength carbon fiber. It was already being used in golf club shafts and fishing rods, but from the very beginning, Toray was aiming for airplanes.

After the first oil crisis in 1973, airplane manufacturers were looking for new materials that could make their planes lighter and more energy efficient. Up to that point, carbon fiber was used in the secondary structures—rudders, those kinds of things—but not for the major load bearing parts of the aircraft, the wings and fuselage.

──Toray was leading the carbon fiber market at that time, making things like golf club shafts, fishing rods, and secondary structures for aircraft. There were a lot of challenges, though, weren’t there?

The process starts out with acrylic fiber, an organic fiber, which we treat at a high temperature to separate out all the non-carbon elements. Nylon and polyester are licensed from other companies in Europe and the US, but we’ve been making our own acrylic fiber since 1959. Since Toray was producing its own acrylic fiber, we had control over the start of the carbon fiber process. We were able to have more original designs in our raw materials.

It’s a lot like cooking, really. The raw ingredients are important. Even if you’re using the same temperatures and the same recipe, being familiar with the material has an impact on the final result.

──So that’s how Toray took the lead in carbon fiber research? Being able to produce the starting material gave you a head start?

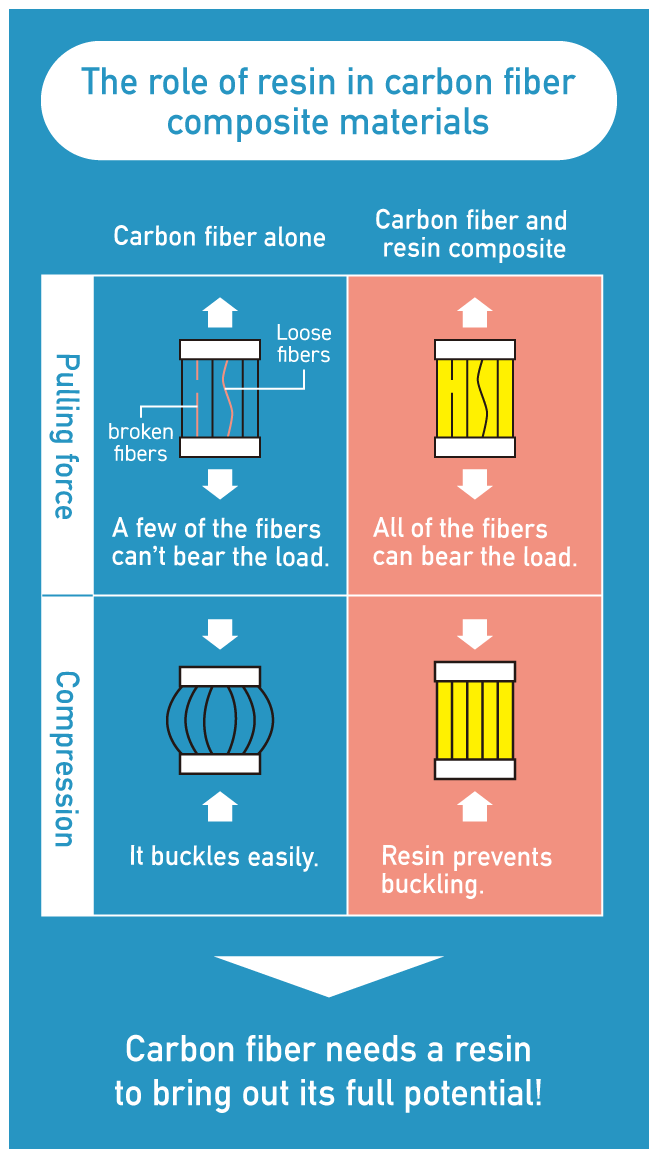

Right, but that’s not all. Really, carbon fiber becomes useful in industrial applications when it’s combined with resin and other materials. Like hair or rope, the fibers are strong against a pulling force, but if you compress them in the other direction, they squish up and release all that force outward. To put it another way, you can use carbon fiber to suspend a heavy object from above, but you can’t use them to support an object from below.

This is where the resin comes in. What kind of resin can you combine with the carbon fibers to improve their compressive strength, and how should you combine them to get a material that’s stronger than just the carbon fiber alone? That was one of our big challenges, finding a way to make a high-strength carbon fiber composite.

Almost in anticipation of this problem, we established our Composite Materials Research Laboratories in 1971, the same year that we started mass producing TORAYCA T300. We wanted to explore the potential for carbon fiber composites, and made that a central focus of research. Those labs have been looking into resin combinations and finishing methods for producing the kinds of carbon fiber composites we had in mind. What happens when you mix carbon fiber with resin? How should you mix them? Should you coat the fibers, mix them, immerse them in the resin…? These are the kinds of processing questions we’ve been studying over and over.

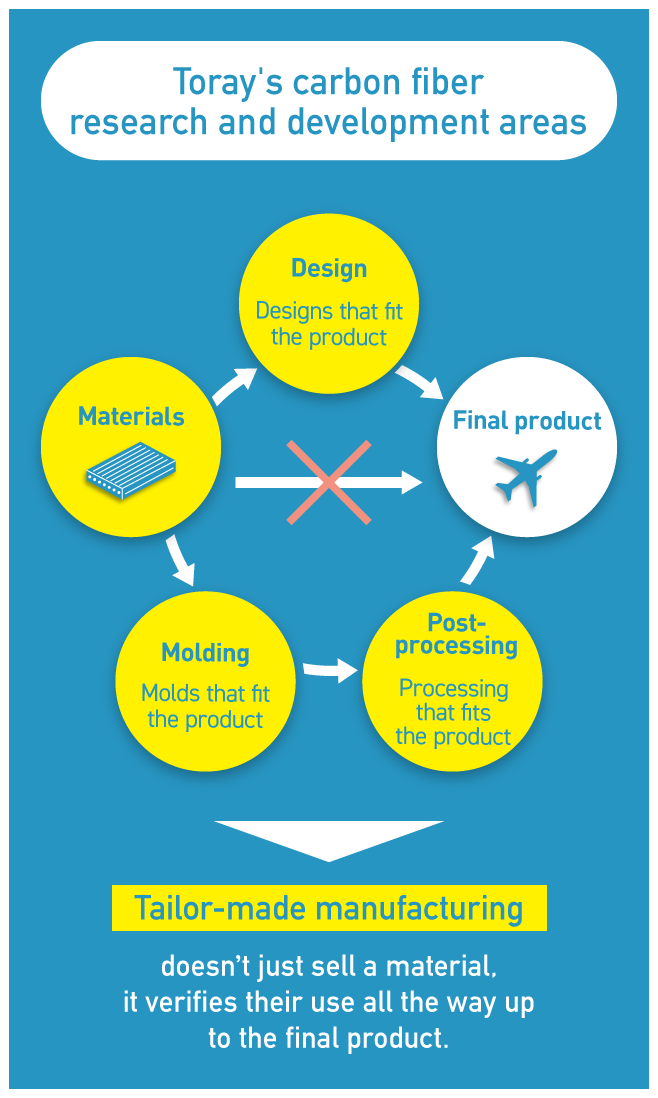

But beyond that, you can’t put a material into practical use without a design, no matter how good that material is. We don’t need the same fiber in every kind of composite—it depends on the application. You can intermix stronger fibers and stretchier fibers in strips, or you can use them for every second fiber. There are infinite possibilities for combinations.

That said, carbon fiber composites are complex and difficult to handle. There are very few players in the industry willing to put in all the time and effort to design and process them. That’s where we stepped in. While Toray is developing all of these tougher carbon fiber composites, the engineering team is constantly offering customers advice on how to use the materials to fit their needs. It’s tailor-made manufacturing.

We look at the manufacturing process as a cycle, connecting everything together like a ring, from providing know-how on the development of starting materials, to research on stronger composites, up through verifying the application and mold processing technology that goes into the final product.

I think that’s why we’re leading the field.

■Joint development with manufacturers, with a marathon runner’s approach

──Toray’s carbon fiber composites are now being used for the primary structures of airplanes, for places like tail fins and floor panels. Is it because of that process you’re describing?

Of course the technology is important, but it’s more than that. It’s also about trust. Boeing works with us on developing the carbon fiber composites, and we give them access to see some of our proprietary development technology.

──Isn’t there a certain amount of risk there, with sharing that kind of information?

Absolutely. But if we release an airplane with a lot of secrecy behind it, we could get in a lot of trouble if something happens. When we share our thinking on a project and tell our partners, “This is what we’re doing and this is why,” we earn our partner’s trust.

We’re constantly creating, destroying, and creating again. That’s how we gather data and perfect our composites to the point that we can say they’re 99.9% safe. Seeing that process helped Boeing decide to put our composites in their planes.

Above and beyond the material certification, we also run tens of thousands of tests on long-term durability. For example, we ran environmental resistance tests for extreme conditions. At an altitude of 12,000 meters, the temperature outside an airplane can drop as low as 55 degrees Celsius below zero. If the plane needs to land from that height within a space of five minutes, it would need to withstand a temperature spike of somewhere between 80 and 100 degrees. So we ran a heat resistance test, called a thermal spike, tens of thousands of times. The conditions were so severe that we actually managed to break the measuring equipment!

We also set up an R&D center in the US, near Boeing, so we could respond more quickly. Maybe it’s a very Japanese thing to do, but we wanted to show that we weren’t just honest and transparent, we were also able to respond quickly. As a material provider, that’s the kind of responsibility we need to take—and we want to be able to sleep soundly at night, too! (laughs)

I think they could see we had an uncompromising attitude toward safety and quality, and that helped us win their trust. Toray has been working more and more with Boeing over the last several years, collaborating on development, and that relationship hasn’t changed at all.

──Was Toray collaborating much with other manufacturers back in the 70s, when they were producing things like fishing rods?

In those days, glass fiber was the primary material for reinforced fishing rods. Replacing the glass fiber with carbon fiber drastically reduced the weight of the rod, and that made it easy to demonstrate the advantages of carbon fiber to manufacturers. But simply telling the customer that the material will be lighter won’t win their trust. We poured our resources into a material design and mold processing research unit dedicated to fishing rods, and we put together materials that could demonstrate the manufacturing process to our clients.

We get our clients’ trust by showing evidence for our products. We don’t need to act like some kind of a “yes-man,” bowing to every request that comes from a manufacturer. It’s pretty hard to trust a bunch of “yes-men.” (laughs)

■From 0 to 1, from 1 to 100: The secret of cross-disciplinary development

──We often hear that large companies can’t manage a quick response. Why is Toray able to offer such speedy research and development?

One of our strengths is our ability to bring together techniques and technologies from different fields and create something new.

When a problem crops up, we can put together a team to solve it at the Technology Center. Our Technology Center consolidates all of our R&D functions, including not only the Composite Materials Research Laboratories, but also the Fibers & Textiles Research Laboratories and the Engineering Development Center. The Technology Center became a kind of sanctuary for us, and it’s played a very important role in devising new solutions and boosting customer satisfaction, bringing in expertise from across the field.

This is all thanks to the organization created by our CTO, Koichi Abe. He always says, "We can’t create something new without bringing together technologies and knowledge from different fields.”

A single researcher can take a new technology from “zero” to “one,” but quick development from there relies on the strengths of an organization. How can we maintain the quality and quantity of communication under COVID, when we can’t meet in person? It’s an important issue for R&D.

──Are you involved in any other pilot research for materials now that don’t yet have a practical application?

I’m also working on my own “underground research” (a system that encourages researchers to spend 20% of their working hours on independent research), thinking about the future. Just taking on customers’ requests won’t produce real technological innovation. That’s why I’ve been working hard on research that doesn’t have any obvious practical application within the next 15 years. I use 20% of my lab time dreaming. (laughs)

──And what is your dream?

It’s a very personal dream of mine, but I want to use carbon fiber composites to make a flying car and a space elevator. (laughs)

Maybe it sounds like a kid’s dream, but R&D needs people who say crazy things. Just like with carbon fiber, it starts out with people saying, “Shut up about these impossible ideas!” Eventually, something you create for another purpose ends up contributing to multiple different businesses. But just like with carbon fiber, that kind of research takes a lot of time. That’s why I feel like my immediate mission, right now, is to support our current society with carbon fiber.

Under COVID-19, the aircraft industry in particular is really suffering. Even so, moving people and goods is a fundamental part of industry, and the role of airplanes in doing that hasn’t changed. That’s why we’ll need further innovations in carbon fiber composites to support the aircraft industry, and as a researcher, I want to support that.

Produced by: NewsPicks Brand Design

Edited by: Ryoya Kaitatsu, Koji Uno

Written by: Satoshi Asahara

Design: Kana Tsutsumi