- HOME

- Can AI innovate in the realm of materials? The vanguard of material science for the next fifty years

Can AI innovate in the realm of materials? The vanguard of material science for the next fifty years

Through an array of new technologies, new materials are emerging that will support the future of medical care, the environment, and our daily lives. To research these possibilities, Toray established their R&D Innovation Center for the Future in 2019 in Shiga Prefecture. Using materials informatics, AI, and open innovation, the Center aims to develop new, innovative materials for future solutions.

Toray has used the power of materials to enrich our lives. What do they have planned for the future? We caught up with some of the leading researchers at the R&D Innovation Center for the Future to ask them about the current state of materials development, and what those materials will mean for the world fifty years down the road.

■What is materials informatics?

Toray Industries’ predecessor, Toyo Rayon Co., Ltd., was founded in 1926, just as the age of synthetic fibers was beginning. They chose the city of Otsu, in Shiga prefecture, as their base of operations.

Today, that site is now Toray’s Shiga plant, home to five different research laboratories, including the Electronic & Imaging Materials Research Laboratories and the Advanced Materials Research Laboratories. The new R&D Innovation Center for the Future joined them in 2019.

By pushing materials research to its limits, Toray has developed a wide range of innovative materials, such as carbon fiber composites, reverse osmosis membranes, and ultra-fine microfiber cloth. Toray has kept its vision focused on the future, looking forward fifty, even one hundred years into the future, developing high functionality polymers, plastics and rubber.

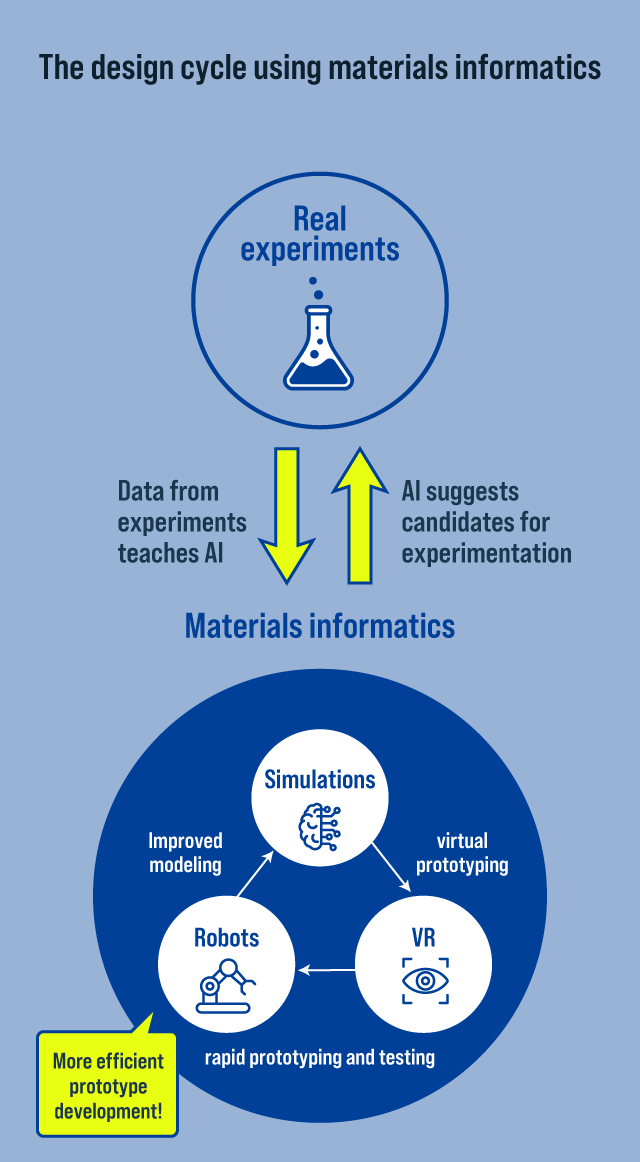

Now the introduction of AI in research is putting the spotlight on the emerging field of “materials informatics,” using AI to predict the physical properties of new materials under development.

Asked about the potential for AI in materials development, General Manager Yoshiki Makabe of Toray’s Advanced Materials Research Laboratories says, “Materials informatics will bring big changes to the course of materials R&D.”

“If we can put AI to good use, we’ll be able to build more sophisticated predictions of our material designs, which will lead to more efficient research.

Up to now, we would set a goal, develop a material, produce a prototype, run an internal evaluation, and take in customer feedback. After repeating that process over and over, we would eventually, finally start mass production.

We can use digital technology to make this back-and-forth process more efficient, from planning up to mass production, and that’s the primary goal of materials informatics.” — Dr. Yoshiki Makabe

But modeling the behavior of plastics and other polymers in a simulation is harder than you might think. Polymers change their properties whenever you mold them, process them, or mix them with additives. We asked Isamu Shigemoto and Umi Yamamoto, two Toray specialists in computational polymer science, to explain the difficulties involved.

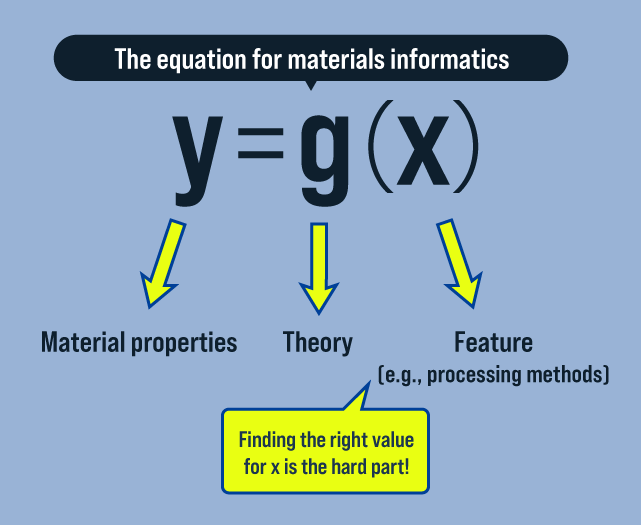

“To predict the physical properties of a material, let’s start with the equation y=f(x). Given a theoretical function f, we can input a numerical value x, and predict the physical properties of the output, y. But choosing the appropriate x is the hard part, whether we’re talking about a chemical structure, a mold processing method, or both.” — Dr. Isamu Shigemoto

“In terms of machine learning, x represents a ‘feature.’ It’s a quantitative variable for expressing the ways Toray has conducted materials research. But the sheer volume of research that Toray has done is so massive and so complex that just setting a feature is already a huge barrier.” — Dr. Umi Yamamoto

When it comes to polymers like plastic, the physical properties are determined by the combination of the microstructure expressed in the chemical formula and the processing methods used. It’s particularly hard to assign values to the processes involved, and that makes it difficult to define the characteristics of the material.

But that’s not all. Even if researchers manage to use the massive amounts of research data that’s available, most of that data is in the form of reports and journal articles. Information written for human readers needs to be converted into data usable by machines.

On top of all that, IT companies with deep experience in applying AI are starting to design molecular materials. Toray finds itself competing not just with other material manufacturers, but also with IT companies with enormous reserves of data.

Given these harsh realities, Dr. Shigemoto, drawing on his twenty years of experience in computational science, tells us, “Toray has an x that no one else has. We know about ‘features’—processes and techniques—that only Toray possesses. That’s our strength.”

“We can talk about all kinds of data, but Toray has more than just theoretical calculations. We’ve got exclusive access to physical data from our own research and production facilities. Collecting primary data takes time and effort. That’s Toray’s x. For everything else, we can borrow public data.

We’ve figured out Toray’s competitive advantage, and that’s where we focus our resources. By doing that, we can contribute to the field of materials informatics in ways that only Toray can.” — Dr. Shigemoto

■It all starts with the researcher’s imagination

It used to be that researchers were hesitant to experiment with a new idea. The time and effort involved, as well as the risk of failure, created a barrier to new research. But as Drs. Shigemoto and Yamamoto have shown, materials informatics allows researchers to quickly predict the results of an experiment, breaking down the barriers for innovation.

“If we can figure out the principles governing the appearance of physical properties in a material, we can use those principles to make predictions when we’re developing a new material.

We’re hoping first of all that repeating this process will make experiments more efficient and shorten the R&D process. But no matter how efficient your process is, the first step is always imagination. That’s exactly why we need materials informatics. We need to use AI to reduce the amount of time we spend on the process and increase the amount of time we spend imagining.” — Dr. Shigemoto

“At this very moment, we’re teaming up with people from different departments throughout the company.

Streamlining the process means that researchers will have more time for thinking. Expanding the range of ideas, that’s the role of materials informatics.” — Dr. Yamamoto

According to Toray CTO Koichi Abe, researchers will be working alongside AI in the future.

“We should put the efficiency of machines to good use for screening, things like that. But I personally believe human beings are essential to the process. Human researchers aren’t going anywhere. As someone who has been in R&D for a long, long time, it’s clear to me that the initial idea is discontinuous, you can’t explain it logically. ” — Mr. Abe

AI doesn’t steal researchers’ jobs — it frees them up to spend their time on more essential work. Using AI to its fullest may allow the next genius researcher to release their creativity in a world-changing invention.

“All data is valuable. Not just successes, but failures, too. The sticky notes we all use today were the result of a botched attempt at making glue. Failures we make now may build the basis for our successors to build something interesting five or ten years down the line.” — Dr. Shigemoto

In other words, materials informatics, along with all of the data it generates, will form the infrastructure driving Toray's next generation of research.

Just like CTO Abe, General Manager Yoshiki Makabe of the Advanced Materials Research Laboratory believes that technology and data will let researchers turn their attention back toward creating things.

“Future researchers will need a free and masterful command over technologies like AI. Just being able to use the tools won’t create new materials. The starting point is always going to be imagination. Only imagination can turn a zero into a one. You can’t suddenly go from zero to one hundred.” — Dr. Makabe

Toray sees a need for perspectives from different fields in building a sustainable future society, not just from materials informatics and computer science, but from social sciences and the humanities.

That’s where the R&D Innovation Center for the Future comes in.

The center consists of two buildings: The Integrated Research Building, where ideas are created, and the Experimental Research Building, where prototypes based on those ideas are created and tested. But what makes the center unique are the labs and common areas for interaction, promoting open innovation and the exchange of ideas between industry, government, and academia.

2nd floor office area

2nd floor library and common area

“The core of Toray’s work for the next generation will be born here. That’s our mission at the R&D Innovation Center for the Future. Open innovation is absolutely indispensable for our work. Collaboration on our proprietary technologies is important, of course, but we also need to be reaching outside the company.

The computational polymer science team, including Drs. Shigemoto and Yamamoto, are actively participating in outside projects, like the ‘K’ and ‘Fugaku’ supercomputers.” — Dr. Makabe

These days, much of the innovative research that goes on to win Nobel Prizes comes as a result of collaboration between researchers and analysts. It’s as difficult now as ever for a gifted researcher to come up with an idea on their own and develop it into a new, innovative technology.

In Dr. Shigemoto’s words, “The future of materials research will require the trinity of manufacturing, analysis, and computational science.” Competitive research will come from teams working together. In that world, what personal qualities will researchers need to create innovative materials?

“Without exception, our best researchers at the R&D Innovation Center for the Future are engaged in independent research. They’re free to study whatever field interests them. For a researcher, one of the most important tasks is to categorize and catalogue the unknown.

That’s precisely why it’s so important for an individual to have the imagination to set up a challenge, as well as the capacity to work with a team to make it a reality. Without that, all you get is complacent, self-absorbed research without any direction. — Dr. Makabe

It’s not enough to simply want to build a flying car, for example. We also have to consider how a flying car might change our society, what could be achieved with it, and what sorts of materials would be needed.

This is the level of deep thinking required of researchers at the R&D Innovation Center for the Future. It’s not enough to wait for the world to catch up with the research. We have to bring the world forward with us.

“Young researchers are contemplating their future, more so than my generation. Rather, they have to be. I’m hoping that the researchers at the R&D Innovation Center for the Future will set the right challenges and create the innovative materials necessary for the future we deserve.” — Dr. Makabe

Produced by: NewsPicks Brand Design

Edited by: Ryoya Kaitatsu

Written by: Satoshi Asahara

Photographs by: Hao Moda

Design by: Yuka Sunada