- HOME

- Beyond Manufacturing: Co-Developing LifeWear to Change the World

Beyond Manufacturing: Co-Developing LifeWear to Change the World

HEATTECH, AIRism, Ultra Light Down. These are just some of the popular products sold around the world as UNIQLO “LifeWear”. However, it is not just UNIQLO products that are well known: parent company Fast Retailing is often cited as an exemplary case of successfully applying a vertical integration model in business management.

In the area of product development and manufacturing, the company established a strategic partnership with advanced material manufacturer Toray Industries, forging a strong relationship over the years.

It is often said that collaboration between different industries is crucial in order to drive innovation, but there have been only a few successful examples of this in Japan. Why then have UNIQLO and Toray been able to establish such a prosperous partnership?

The story began at a management meeting between the two companies that took place back in 2000.

■A Global Perspective on the Textile Industry

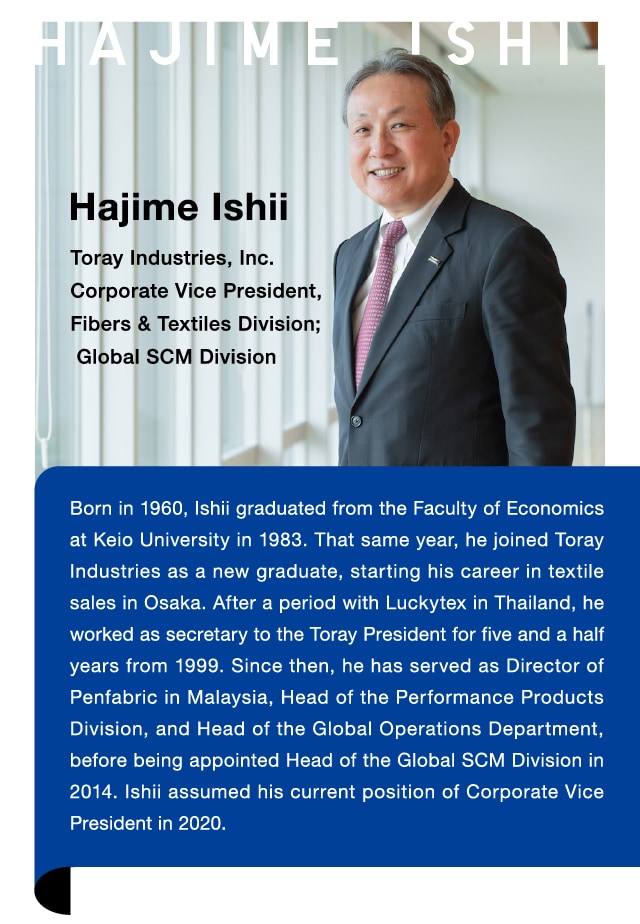

Hajime Ishii (Toray Industries) : The first time Fast Retailing CEO Tadashi Yanai visited our office to discuss a potential partnership, I was working as a secretary for Katsunosuke Maeda, the then President of Toray.

I actually brought my notebook from that time with me today. It says here that on April 24, 2000, at around 2 pm, Tadashi Yanai and a group of Fast Retailing executives participated in a meeting at our office. Look, your name is mentioned right there, Nakajima-san.

Shuichi Nakajima (Fast Retailing) : Ah, that takes me back. UNIQLO’s fleece products had just become a big hit, and we were finally becoming a household name. I recall Mr. Yanai would often say, “If we want to make unique and innovative products, we must find business partners with the right know-how in terms of technology and product development”.

He was convinced that Toray could be that kind of partner. That’s why on that day he gathered all the company’s executives and we went to Toray’s office. Mr. Yanai wanted to properly convey our enthusiasm and firm desire to collaborate with you.

Ishii: We were absolutely delighted to welcome you! Truth be told, around that time, many believed that Japan’s textile industry had had its day. But Mr. Maeda was adamant that it had a lot of growth potential when viewed from a global perspective.

I can vividly recall leading Mr. Yanai to Mr. Maeda’s office that day, where they talked one-on-one for around 30 minutes.

Nakajima:While that was taking place, all the executives, including me, were waiting in a separate room. Then Mr. Yanai emerged from the meeting room and stated very matter-of-factly, “We will be partnering with Toray.” That was that. It was the start of the collaboration between our two companies.

In 1998, UNIQLO launched its fleece products that would go on to make fleece a household name. They were a huge hit, and sold millions in Japan. Fast Retailing CEO Tadashi Yanai visited Toray in 2000, right after this “fleece frenzy”. UNIQLO subsequently began to expand into other Asian countries and the U.K.

Ishii: Looking back on the history of this partnership, it began with Toray assisting with the production of UNIQLO fleece products, but later expanded to include collaboration on material development, manufacturing facilities, and supply chain.

I was first put in charge of UNIQLO-related operations in 2013 and was astonished to see just how far the partnership had come.

Nakajima: It’s been a real team effort, with continuous improvements made year after year.

I believe the compatibility of our corporate philosophies was a major factor in convincing Mr. Yanai that Toray was the perfect partner for UNIQLO. Toray’s message of “Materials Change Our Lives” resonates well with the Fast Retailing mission, “Changing clothes. Changing conventional wisdom. Change the world.”—a mission we are pursuing through our LifeWear concept. The meeting with Mr. Maeda that day convinced Mr. Yanai that Toray could become a trusted partner for this journey.

Collaborating with a company from a different industry, particularly to this extent, was a first for Fast Retailing too. I believe the top-down decision made by both companies on that day enabled us to ultimately develop the strategic partnership we have today.

■The Fruits of Collaboration

Ishii: I suppose HEATTECH might be the first product that our companies co-developed, in the true meaning of the word. It started in 2003, when we received a request from UNIQLO asking us: “Can you develop a thin and warm material that could be worn under denim?”

We immediately set about developing new types of fibers, and in 2006 the first HEATTECH product—a combination of four types of fibers—saw the light of day. That same year, our companies signed a strategic partnership, and we have continued to work closer and closer on development ever since.

Nakajima: As we have envisioned it, our LifeWear is designed to enrich the daily lives of each and every person who wears it. To deliver on this goal, new material technologies and product development capabilities are a must.

UNIQLO doesn’t produce materials, nor do we operate factories ourselves. What we do is listen to our customers’ needs, think about what we wish to make for them, and develop these products in collaboration with our partners. We then communicate the value of these products to our customers and deliver them.

Toray’s product development and technological capabilities are invaluable in giving shape to our concepts.

Ishii: From our perspective, developing new types of fibers for just one client would have previously been out of the question. It would have simply cost too much, and we would have had to turn down such a request.

What made UNIQLO different, however, was its commitment to operating a dedicated production line and selling enough products on a consistent basis to make it profitable over the long term.

Before UNIQLO, there simply weren’t any clients that could provide such a commitment. Seasonality is a big factor in the apparel industry, and our materials would often just be used for one season, before being dropped.

In contrast, UNIQLO’s goal was to deliver LifeWear for men and women of all ages, on a global scale. This business model was a key factor in enabling us to consistently develop and produce materials.

Nakajima: The strong commitment demonstrated by those at the top was crucial, I think. Mr. Yanai has, again and again, told everyone at the company that we will always work with Toray, even when times are tough.

Naturally, there were a few problems at the outset. Before Toray, we had only been concerned with finished fabrics, but now suddenly we were involved in fiber development.

For us, Toray’s material development process seemed to take an awful lot of time, longer than we had been used to. I remember some colleagues at UNIQLO commenting on how time consuming it was to work with Toray. There were definitely some concerns raised in the beginning.

Looking back at it now, however, these initial concerns were clearly the result of our lack of knowledge about the material development process. We didn’t fully appreciate Toray’s passion and energy for technology.

But the more we worked with Toray, as one team, and the more results our partnership generated, the more positive the attitude became in the company.

Ishii: We have also seen so many positive effects from working with UNIQLO, in many different ways.

Prior to our partnership, Toray employees working in factories and laboratories had little opportunity to see the products they helped make on display in stores. Working with UNIQLO, however, they could now see their creations being directly evaluated by end consumers.

For a manufacturer of materials like Toray, this exposure brings with it great pressure but is also a deep source of motivation. We have learned a great deal from UNIQLO’s ability to truly listen to customers and their needs.

Seeing how the materials we produce are used by people in their day-to-day lives made us realize that we need to be more attentive to our customers’ voices too.

Working with UNIQLO has brought fresh perspectives to the Toray workplace and has brought about significant change in the company—change very much for the better.

■Mutual Understanding Makes for Better Products and Experiences

Nakajima: When you collaborate with others to get to that next level, all parties need to share a deep understanding of each other’s operations, from manufacturing right through to sales.

Our core goal at Fast Retailing is simple: to deliver quality clothing that makes our customers happy. To make this happen, we needed to better understand how clothes were made, and how we could make them better—that’s another area where we learned a great deal from Toray.

Armed with this knowledge, we were able to make suggestions to Toray to enhance the functionality of our products, communicating one or two steps ahead.

Correct me if I’m wrong, Ishii-san, but I believe Toray has seen something similar happen.

When the partnership had just started, our requests were pretty much carried out as instructed. However, as both companies grew closer and Toray gained a deeper understanding of our culture at UNIQLO, we began receiving more and more suggestions from Toray employees on the types of products they thought would appeal to our customers. Through such close cooperation, we have both honed our ability to connect materials and functionality to the overall experience customers have with our clothing.

Without a thorough understanding of each other’s thought process, requests inevitably end up lacking depth. You must have an extensive mutual understanding to make a request that has sufficient depth and detail.

Ishii: I completely agree. Toray is a manufacturer, and so we have traditionally had a largely vertical, siloed business structure. Our work with UNIQLO, however, has helped us improve collaboration in a horizontal way, both internally and externally.

Breaking away from the limits of sectionalism was very significant for us, and this culture has since spread to our other business domains outside of textiles. For example, we can also leverage our resources in biotechnology and carbon-based materials to provide even greater value to our partner, UNIQLO. Beyond that, it has also helped us to visualize the consumers that will ultimately be using the materials that we develop.

I am very much looking forward to seeing the kind of innovation this will create in the future.

■How Can Co-Creation Change the World?

Nakajima: Simply calling our partnership a collaboration between a material manufacturer and an apparel company is a bit misleading, I find. UNIQLO doesn’t just order fabrics from Toray.

Our collaboration with Toray starts from a very early stage in the development process, where we discuss what kind of product we can make to meet the needs of customers. Through these discussions, we’re able to understand each other better and build trust.

UNIQLO sees itself as an information-driven manufacturer-retailer, and the trust that we’ve built with partners like Toray means that we have a degree of control over the production and throughout the entire supply chain. But we didn’t achieve this overnight.

Ishii: We have a cycle where we create new prototypes of materials in discussion with UNIQLO, then remake them, discuss again, then do it again—particularly when it comes to developing technologies for the medium to long term future. The end result of this collaborative process is innovative LifeWear like HEATTECH, AIRism, and Ultra Light Down, which UNIQLO sells around the world today.

Nakajima-san and his team, as well as people within Toray, always ask us, “What amazing things are you planning for us next?”. It’s honestly a real challenge to keep up with their expectations!

To give you an example, there was a project to develop the Ultra Stretch Active Jogger Pants (“Active Joggers”), which began in the summer of 2015. Our President Akihiro Nikkaku discussed it with Mr. Yanai, who requested that we make thread using new innovative polymers.

After talking about it internally, we proposed a material to UNIQLO that used a new stretch polyester thread. This idea was well-received, but UNIQLO then asked if we could make it not just stretchable, but also quick-drying. The product launched in 2017 with the original materials, but we continued working on improvements even post-release. These efforts were ultimately rewarded in 2020, when we saw a remarkable surge in demand for Active Joggers as people started spending much more time at home due to the pandemic.

UNIQLO Ultra Stretch Active Jogger Pants launched in 2017

Nakajima: This example shows how the release of a product is not the end of the story. The popularity of Active Joggers far exceeded our expectations, and we didn’t have enough in stock to meet demand.

We needed to do something about that, so we asked Toray to boost their production capacity for this particular line, and that gradually helped resolve the supply shortage issue.

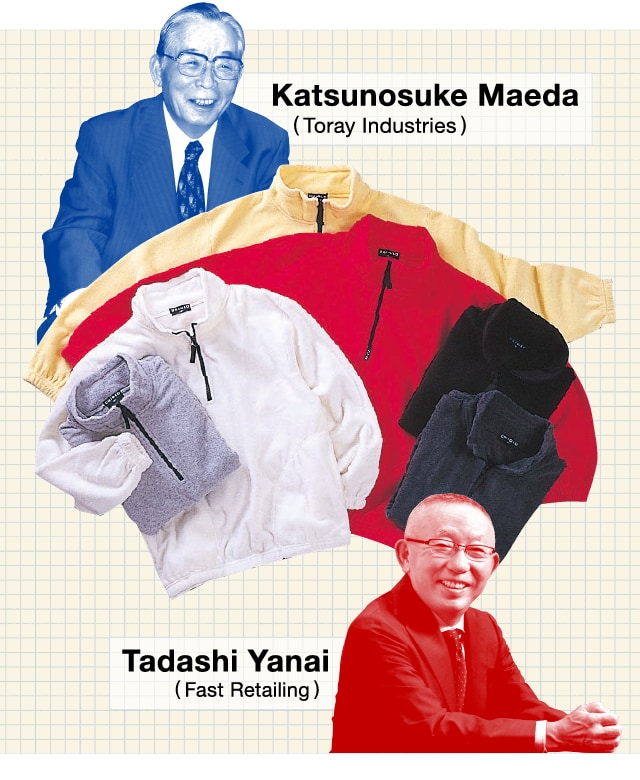

Ishii: Incorporating customer feedback into the product development process, the idea of making a product while also selling it, integration on an information level—this is all key to improving the accuracy of production planning.

Toray’s manufacturing technology allows us to turn new types of fiber into textiles and sewn products that can be mass-produced quickly and have a uniform, high level of quality. And we work very closely with UNIQLO, making sure that all information, from our global supply chain to merchandising, marketing, and management, is properly shared.

Just as one example, we’ve set up a hotline system with all our suppliers, including our sewing factories, through which workers can communicate their thoughts and opinions to UNIQLO directly. Although there are no capital ties between Toray’s factories and UNIQLO, we still believe that increasing the transparency of all aspects of the production process, from factory equipment to the working environment, leads to greater trust when it comes to quality.

At factories overseas, both companies work closely to ensure the maintenance of equipment, cafeterias, and sanitation standards, including measures to prevent COVID-19 infections. Toray’s plant in Bangladesh implemented a mobile phone-based electronic payment system, which has further enabled female employees to manage their own salaries. The sign with the motto in the photo above reads, "Our products is same as mother's Birthday Present".

Nakajima: Our goal with LifeWear is not only to enrich the lives of the people who wear our clothes. We also wish to enrich the lives of the people who work so hard to produce them as well as their families.

When customers choose our clothes, we want them to feel reassured that they were produced in a good working environment. That’s why we’re so open about our factories, and it’s also why we can deliver our products to customers with a great sense of confidence and pride.

■Making LifeWear Sustainable

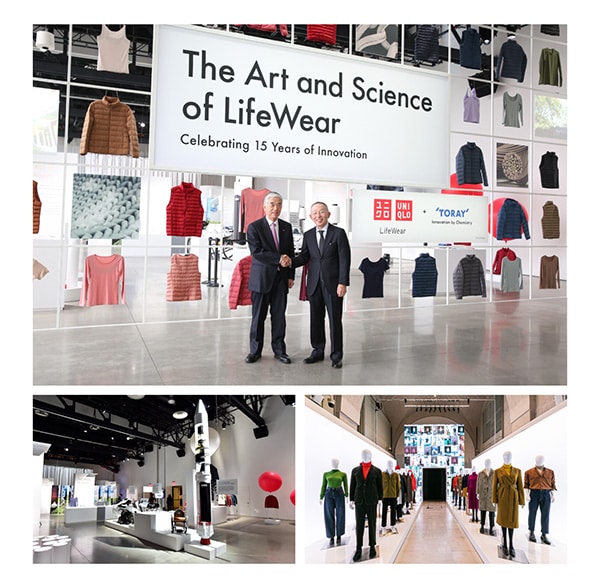

Ishii: In 2017, UNIQLO and Toray hosted “The Art and Science of LifeWear,” a large-scale exhibition in New York City.

Before that, Toray used to hold its annual “Toray Advanced Materials Exhibition” in Japan, but it was unclear exactly how our technologies could be leveraged to drive real change on a global scale. The LifeWear event presented an invaluable opportunity for us to communicate a message globally alongside a trusted partner in UNIQLO.

Since then, we’ve also held similar exhibitions in Paris, London, and China. At the London exhibition in September 2019, we first announced the development of LifeWear products centered on sustainability. These were Dry EX, which are made from a new type of materials recycled from plastic bottles and Recycled Down, which are produced from recycled Ultra Light Down clothing. Both were very well received.

Top: Toray President Akihiro Nikkaku and Fast Retailing CEO Tadashi Yanai at the joint exhibition in New York City; Bottom Left: at TheArt and Science of LifeWear event in New York City; Bottom Right: a similar exhibition in London in 2019.

UNIQLO products, and the technologies that go into making them, attract a lot of attention worldwide. This attention from the global community has given Toray employees a lot of confidence and pride in their work.

Nakajima: From now on, it’ll become increasingly important for manufacturers to minimize their environmental impact. And since we aim to provide clothing that enriches people’s lives, it’s very much our responsibility to ensure that we’re working towards sustainability in our own operations, from production right through to sales.

However, this doesn’t mean that we need to sacrifice quality, performance, or comfort to protect the environment. Instead, we wish to keep delivering innovative clothing to customers that are both environmentally sustainable and offer high quality and comfort—and continue improving them.

“Changing the world” may sound like an ambitious vision. Still, I believe that the effective combination of UNIQLO and Toray’s assets can help us get closer to making it a reality.

Ishii: I couldn’t agree more. We are also constantly refining our technologies and trying to push the limits in the name of our “Materials Change Our Lives” message. Our collaboration with UNIQLO on LifeWear has provided us with proof that the technological advances we pour our heart and soul into are actually making a difference to consumers and society.

Produced by NewsPicks Brand Design

Edited: Koji Uno

Composition: Tetsuya Saito

Photography: Kazuya Hayashi

Design: Seisakujo inc.

English Translation: Luke O’Donovan, Victor Makhnutin