Toray Industries, Inc.

Tokyo, Japan, April 17, 2023 – Toray Industries, Inc., announced today that it and Mitsui DM Sugar Co., Ltd., have jointly demonstrated and established a basic technology to manufacture sugar derived from inedible biomass (see note 1), a common raw material in fiber and resin production. The biomass includes surplus bagasse (note 2), a pulpy residue from sugarcane processing, and pulp that results from squeezing cassava (note 3) at starch factories.

Bringing this technology together with another that Toray is developing to create monomers from sugars should contribute to a circular economy by making it possible integrate the production of biomass-based polymers for fibers, films, resins, and other offerings.

This demonstration project entailed Toray verifying a process to separate, purify, and concentrate cellulose-derived sugars in inedible biomass. It leveraged a membrane-based bioprocess that combines the company’s water treatment membrane technology and enzymes that employ biotechnology. Toray undertook this effort at a demonstration facility in Thailand as part of a project that the New Energy and Industrial Technology Development Organization (NEDO) is supporting. The company proved that carbon dioxide emissions from this process are less than half those of conventional production setups that concentrate sugar solutions by evaporating water (see Figure 1).

Figure 1. Production of Cellulosic sugar from bagasse with membrane separation technology.

In 2022, Toray developed a 100% bio-based adipic acid, a raw material for polyamide 66 (nylon 66), from sugars derived from inedible biomass. This achievement came from using a proprietary synthesis technique combining the company’s microbial fermentation technology and chemical purification technology that harnesses separation membranes. The recent demonstration was a first step toward creating a technology to make cellulosic sugar from biomass, putting it on track to mass production. The company now looks to establish an integrated technology to manufacture fiber and resin from abundant agricultural residue, avoiding competition with the food chain (see Figure 2).

Figure 2. Concept for transforming inedible plants into chemical raw materials

Toray looks to set up a structure to supply cellulosic sugar in collaboration with Thai sugar refineries and starch manufacturers and other companies using biomass resources. It will endeavor to upscale technology from an effort under development to produce adipic acid from cellulosic sugar. In providing cellulosic sugars to chemical companies around the globe, Toray seeks to help materialize a circular economy by replacing petroleum-based chemicals with plant-derived offerings that are not part of the food chain.

Toray is leveraging a basic policy of creating and deploying innovative new materials and technologies for tomorrow in entering new fields while drawing on internal and external collaboration to accelerate research. As part of this approach, it will engage in open innovation for membrane bioprocessing with players in different industries, establishing supply chains and providing solutions with companies using biomass and cellulosic sugar.

The technology announced today is a fruit of NEDO’s Demonstration Project for an Energy-Saving Cellulosic Sugar Production System using Bagasse under International Demonstration Project on Japan’s Energy Efficiency Technologies. The demonstration plant is at a site in Udon Thani Province, Thailand, of Cellulosic Biomass Technology Co., Ltd., which Toray and Mitsui Sugar Co., Ltd., set up in January 2017. There, Toray verified and assessed manufacturing process energy savings, production performance, and the economic feasibility of this production system from August 2018 through December 2022. It completed the demonstration in March 2023. The Thai government looks for the new technology to contribute significantly to materializing the Bio-Circular Green Economy model, which the Thai Government deployed as a strategy for national development and post-pandemic recovery.

Demonstration project overview

| 1. |

Name: Demonstration Project for an Energy-Saving Cellulosic Sugar Production System Using Bagasse (as part of NEDO’s International Demonstration Project on Japan’s Energy Efficiency Technologies)

https://www.nedo.go.jp/english/activities/activities_AT1_00175.html |

| 2. |

Project period: August 2016 through March 2023 |

| 3. |

Demonstration period: August 2018 through December 2022 |

| 4. |

Location: Udon Thani Province, Thailand |

| 5. |

Facility scale: Dried bagasse processing capacity of 3,000 metric tons annually |

Demonstration technology details

| 1. |

Using enzymes and separation membranes to turn inedible plants into sugars

At the demonstration plant, Toray verified a technology to produce cellulosic sugar as a raw fermentation material for ethanol, lactic acid, succinic acid, and other substances by reacting unused bagasse and cassava pulp with enzymes, using membrane separation to purify and concentrate the resulting cellulosic sugar.

In verifying this technology with bagasse as a raw material, Toray confirmed that it is possible to halve enzyme usage by recovering and reusing enzymes in membranes. Such losses have been costly to date in producing cellulosic sugar.

The company further purified sugars with membranes, separating acetic and other organic acids from cellulosic sugars. It thereby obtained cellulosic sugars offering outstanding fermentability and confirmed that fermentation into ethanol and succinic acid and edible sugars is possible.

|

| 2. |

Cost savings in producing chemicals with proprietary enzyme production technology

Toray upscaled production of the enzyme production technology stemming from its R&D (a non-genetically modified organism enzyme production technology using a trichoderma filamentous fungi; attaining world-class enzyme production capacity). It used the upscaled enzyme production facilities in Thailand to demonstrate sugar production from bagasse. This enzyme production technology should serve as an on-site technology as sugar production systems spread, cutting enzyme costs to help such systems become mainstream.

|

| 3. |

Reducing total chemical production costs by using cassava pulp as raw material

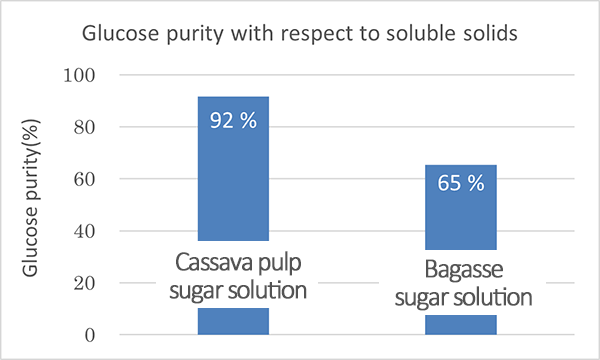

cellulosic sugar derived from cassava pulp does not contain xylose (see note 4). It can be purified through membrane saccharification to remove viscous substances. This results in a sugar solution with higher glucose purity than that of cellulosic sugar derived from bagasse (see Figure 3). Toray also confirmed good conversion efficiency in fermentation through the demonstration effort. The high glucose purity and low impurity content could slash the total costs of manufacturing chemicals. Among them are adipic acid, the raw material for nylon 66. |

Figure 3. Glucose purity relative to soluble solids.

Notes

| 1. |

cellulosic sugar is a solution whose prime component is glucose. It results from decomposing agricultural residue (biomass) that is not used as food. |

| 2. |

Bagasse is a solid residue from pressing sugarcane. Sugar refineries burn some bagasse in boilers to generate electricity; the remainder is called surplus bagasse. Thailand is one of the world’s leading sugarcane producers. |

| 3. |

Cassava pulp is a residue from extracting tapioca. It is used as livestock feed after drying in the sun. It cannot be preserved when undried, creating a need for ways to use it in that state. |

| 4. |

Biomass-derived cellulosic sugars mainly comprise glucose, which microorganisms can easily metabolize, and xylose, which is hard for microorganisms to metabolize. Lower xylose concentrations enhance chemical production efficiency. Bagasse-derived cellulosic sugars normally have a glucose and xylose ratio of 2:1. Cassava pulp-derived cellulosic sugars have very little xylose. |

References

NEDO’s International Demonstration Project on Japan's Energy Efficiency Technologies

https://www.nedo.go.jp/english/activities/activities_AT1_00175.html

Toray news release issued on July 6, 2018

Toray Holds Grand Opening Ceremony of Thai Demonstration Plant for Cellulosic Sugar-manufacturing Process Using Membranes

https://www.toray.com/global/news/details/20180706000470.html

Cellulosic Biomass Technology demonstration plant for cellulosic sugar production technology in Udon Thani Province, Thailand

Toray news release issued on August 24, 2022

Toray Invents 100% Bio-Based Adipic Acid from Sugars Derived from Inedible Biomass, Scaling Up for Application to Eco-Friendly Nylon 66

https://www.toray.com/global/news/details/20220818103248.html