- HOME

- Sustainability

- Product Quality and Safety

- Initiatives for Quality Assurance and Product Safety

CSR Activity Report (CSR Guideline Activity Reports) - Product Quality and Safety

Initiatives for Quality Assurance and Product Safety

Reinforcing Compliance in Product Quality Assurance

Toray Group is pursuing five major tasks to reinforce quality assurance compliance throughout the Group.

- Implementation of quality assurance systems based on group-wide guideline

Toray Industries and its worldwide business sites and group companies have established quality assurance systems in line with the groupwide Guidelines for Target Conditions for Quality Assurance System, which define the roles each department should play in strengthening their quality assurance systems. The Company is working to maintain and enhance the Group’s quality assurance capabilities to reliably meet customer requirements. - Enhancing the quality assurance capabilities of the entire Group by strengthening audit functions

To enhance the overall quality assurance capabilities of the Toray Group, audits of worldwide business sites and group companies are regularly conducted by the Quality Assurance Departments responsible for each business division of Toray Industries. Additionally, the deputy general manager of the Quality Assurance Division and the Quality Assurance Planning & Administration Department audit each of the Quality Assurance Departments, and mutual audits between these departments are also carried out. - Development of human resources and creation of workplace culture not allowing any misconduct

To coincide with the annual Quality Month1 in November, since fiscal 2020 the Group has designated the same period as Quality Assurance Compliance Month and has been conducting quality assurance compliance education during this time of year. Toray Industries provides training materials to its business sites and group companies around the world, while individual departments and companies are responsible for providing education for their employees. (A total of 22,503 employees received training in fiscal 2023.) - Review and adjustment of actual contracts with customers regarding quality (assurance)

In accordance with Guidelines for Contracts/Agreements with Customers on Product Quality and Product Quality Assurance set forth at the time contracts are agreed, Toray Industries is promoting ongoing efforts to thoroughly inspect and review agreements at its business sites and group companies around the world and is working to optimize the provisions in these contracts. - Improvement of quality data management system to not allow any misconduct

Toray Industries and its group companies around the world are developing data management systems that minimize human involvement, such as by automating measurement, transfer of measurement data, and issuance of inspection reports.

- 1 This campaign began in Japan in 1960 with the aim of raising quality awareness at production facilities nationwide and designates every November as Quality Month. It is organized by the Quality Month Committee, the Union of Japanese Scientists and Engineers, the Japanese Standards Association, and the Japan Chamber of Commerce.

Education and Training for Quality Assurance and for Product Safety

Quality assurance compliance education (% of people trained)

- ■Reporting scope

- Toray Group

- ■Target in fiscal 2023

- 100%

Result in fiscal 2023

100%

In addition to quality assurance compliance training conducted during Quality Assurance Compliance Month (November), which targets all employees involved in handling quality data and certification-related tasks, Toray Industries promotes quality assurance and product safety training for newly appointed department and section managers at the Company and its group companies in Japan. It also provides education on quality assurance and product safety activities during company-wide technical training, as well as quality control training for frontline personnel. Toray is working to thoroughly raise awareness of the Group’s quality assurance and product safety activities and improve its quality control capabilities. Moreover, since fiscal 2013, all group companies around the world have conducted general training related to product safety, training for specific business operations, and internal rules training.

The implementation rate for quality assurance compliance education conducted during November, Quality Assurance Compliance Month, has been set as a KPI under the CSR Roadmap 2025, and these activities are being actively promoted. In fiscal 2023, the implementation rate was 100%, helping to raise group-wide awareness of quality assurance compliance.

Implementation of Quality Assurance Audits

Quality and product safety audit implementation rate (%)

- ■Reporting scope

- Toray Group

- ■Target in fiscal 2023

- 100%

Result in fiscal 2023

100%

The implementation rate for audits of worldwide business sites and group companies by the Quality Assurance Departments responsible for each business division of Toray Industries has been set as a KPI under the CSR Roadmap 2025, and audits are being promoted accordingly. In fiscal 2023, the audit rate was 100% for worldwide business sites and group companies, thereby helping to enhance the overall quality assurance capabilities of Toray Group.

Enhancing Product Safety Reviews

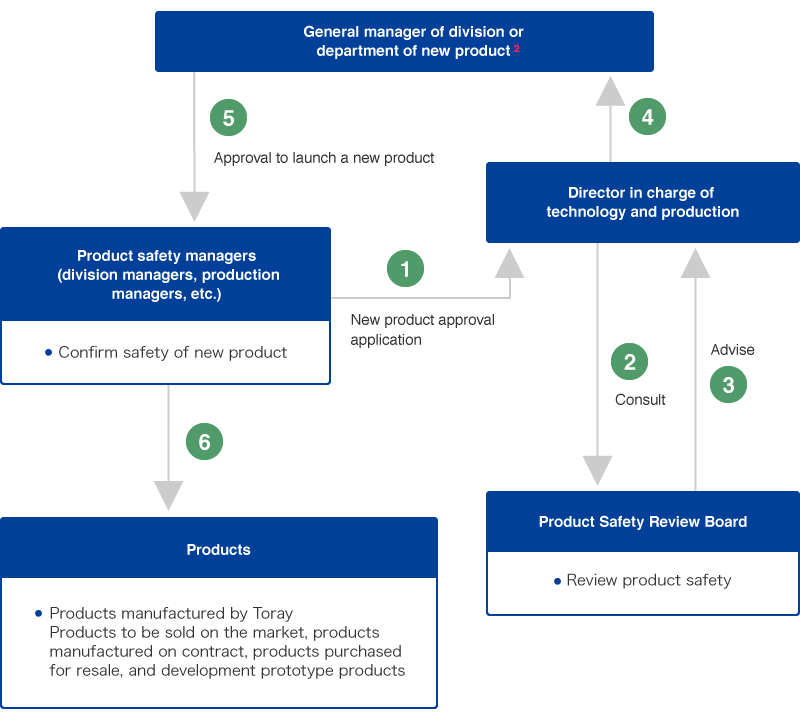

Toray Industries and its group companies implement product safety reviews for all products. In addition to addressing product safety, the reviews examine the adequacy of information provided to customers via, for instance, safety data sheets (SDS), labeling, and instructions. Products are also assessed for impact on the global environment. Special precautions are taken for new products that are highly original, as well as for products for which the safety considerations have changed significantly from previous products. For these products, a Product Safety Review Board comprised of neutral assessors with specialized knowledge is assembled to review the safety of the product. Toray Group also ensures that newly established group companies rapidly establish a framework for product safety and implement product safety reviews.

- Implementing product safety reviews for all products

- 2 At group companies in and outside Japan, this position is held by the president or a director.

Preventing Product Accidents

Number of product accidents

- ■Reporting scope

- Toray Group

- ■Target in fiscal 2023

- 0

Result in fiscal 2023

13

- 3 An incident occurred involving air filter media sold by Toray. During processing of the material at a customer facility, a white powder was noticed and multiple line operators experienced skin irritation. However, their symptoms were mild and completely alleviated with over-the-counter ointments. While an investigation by experts did not establish a clear causal relationship between the white powder and the symptoms, Toray treated it as a product safety incident. Accordingly, the group company that manufactures the air filter media was given instructions intended to reduce any occurrence of the white powder during the customer’s process. After implementation of these measures, no further symptoms occurred.

Providing Product Safety Information

Toray Group provides customers with product safety information specifically tailored to the product or service.

- Customer support lines

In its efforts to create a convenient environment for customers, Toray Industries makes available toll-free numbers for customers to call and inquire about its mainstay consumer products such as home water purifiers and contact lenses. - Safety data sheets (SDS)

Toray Group designates the duties, management framework, and procedures for SDS on products that are manufactured or sold by the Group, and provides customers with adequate information on the safe handling of Group products. SDS are disclosed online so that they are readily accessible to customers. - Product labeling and instructions

Toray Group creates labels and instruction manuals (including catalogs) and provides them to customers only after clarifying the duties and management framework for product labels and instruction manuals, the procedures from creation to distribution, and other key processes.

Respecting the Eight Basic Consumer Rights

In providing products and services, Toray Group is fundamentally committed to respecting the Eight Basic Consumer Rights and strives to secure safety and quality of its products throughout the Group's business activities.

The Eight Basic Consumer Rights advocated by Consumers International

- The right to satisfaction of basic needs

- The right to safety

- The right to be informed

- The right to choose

- The right to be heard

- The right to redress

- The right to consumer education

- The right to a healthy environment

Click here for the main initiatives for CSR Guideline 4, “Product Quality and Safety” in CSR Roadmap 2025.