- HOME

- Sustainability

- Establishing Sustainable Supply Chain

- Toray Group Distribution Initiatives

CSR Activity Report (CSR Guideline Activity Reports) - Establishing Sustainable Supply Chain

Toray Group Distribution Initiatives

Working Together with Business Partners

Holding Basic Distribution Policy Briefings

Basic Distribution Policy Briefing (fiscal 2023)

Basic Distribution Policy Briefing (fiscal 2023)

Toray Industries, Inc. promotes understanding of Toray Group’s distribution policies and works to improve distribution performance with annual Basic Distribution Policy Briefings for logistics companies as part of its ongoing effort to improve quality and reduce the environmental impact of its distribution process. In fiscal 2023, the briefing was held both online and in person, and 71 logistics companies participated.

Participation in White Logistics Movement and Efforts to Improve the Logistics Environment

Toray Industries participates in the White Logistics Movement1, an initiative designed to ensure the provision of the stable logistics necessary for consumers’ lives and for industrial activities, while also contributing to economic growth. In line with the declaration of voluntary activities given below, the Company is actively working to improve the logistics environment based on mutual understanding and cooperation with business partners and logistics companies.

- 1 The White Logistics Movement: In response to the growing shortage of truck drivers in Japan, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT), Ministry of Economy, Trade and Industry (METI) and Ministry of Agriculture, Forestry and Fisheries (MAFF) are working together to encourage the participation of shipping and logistics companies. The aim is to improve the productivity of truck transportation and raise logistical efficiency, while looking to realize a fairer labor environment, thereby making it easier for women and drivers over the age of 60 to work in the industry.

| Initiative | Details |

|---|---|

| Cooperate with the logistics improvement and proposals | Seriously work on eliminating incidental work, etc. that leads to increased duty hours of truck drivers. |

| Use pallets, etc. | Expand use of packing styles (pallets, etc.) that enables loading using forklifts to reduce cargo loading time. |

| Extend lead time | Secure sufficient lead time corresponding to the transportation distance. |

| Take legal compliance status into account | Give utmost priority to assess compliance status with relevant laws upon selecting logistics companies for signing agreements. |

| Actively utilize logistics vendors engaged in working style reforms, etc. | Actively utilize logistics companies engaged in work-style reforms, improvement of transportation safety and logistics quality. |

| Suspend, discontinue, etc. of operation in case of adverse weather, etc. | Give utmost priority to the truck driver's safety in the event of adverse weather, earthquake, etc. |

Addressing the 2024 Logistics Problem Through the Physical Internet Realization Conference and the Chemical Products Working Group

The logistics industry in Japan is experiencing an increase in small parcel logistics, while simultaneously facing a shortage of transportation capacity due to the aging of drivers and boat crews and a lack of human resources. The situation for transportation capacity continues to be challenging as a result. Additionally, with Japan’s so-called “2024 problem”, predictions indicate a 34% shortfall in logistics transportation capacity by 2030. This makes logistics one of the most critical challenges for the chemical industry. Furthermore, chemical products have unique properties, packaging formats, and are often heavy. This results in diverse transport methods and conditions, making it difficult for individual companies to implement effective measures to combat the 2024 problem.

To address these challenges, Toray Industries, alongside Mitsubishi Chemical Group Corporation, Mitsui Chemicals, Inc., and Tosoh Corporation, established the Chemical Products Working Group in July 2023, under the Physical Internet Realization Conference, organized by the Ministry of Economy, Trade and Industry and the Ministry of Land, Infrastructure, Transport and Tourism.

The Chemical Products Working Group currently includes 79 companies primarily comprising shippers and logistics providers (as of July 2024), as well as participants from the Japan Chemical Industry Association, the Japan Petrochemical Industry Association, and relevant departments of the Ministry of Economy, Trade and Industry and the Ministry of Land, Infrastructure, Transport and Tourism. The working group announced a voluntary action plan on March 29, 2024. For more details (in Japanese only), please click here.

Improving Loading Operations Through Plant Logistics Innovation

The Mishima Plant of Toray Industries has faced the issue of trucks waiting for excessive periods of time at the plant’s film warehouse before being able to load. As part of Japan's White Logistics Movement to enhance logistics efficiency, Toray Industries introduced a new digital system to shorten waiting times in fiscal 2021. The drivers can now check the waiting times online before heading to the warehouse and reserve an appropriate time slot.

Also, shipping forms that had been printed out were shifted in fiscal 2022 to electronic form using tablet devices. The elimination of paper forms has reduced the burden on workers and drivers, while also helping to create a paperless society.

| Initiative | Effect |

|---|---|

| ・Reduction of average truck waiting times | 56 minutes per vehicle before implementation 15 minutes per vehicle after implementation (73% reduction) |

| ・Digitization of shipping documents | Before implementation: 120 sheets of paper per day After implementation: 0 sheets of paper per day |

Toray Industries is also advancing similar initiatives at its other plants. The Gifu Plant adopted a loading reservation system and implemented paperless procedures in fiscal 2022 and 2023. The Nagoya, Okazaki, and Chiba Plants have also implemented their own loading reservation systems. The Company will continue to promote internal logistics reforms, thereby helping to improve logistics efficiency as a consignor.

Improving Logistics Productivity by Using Smart Pallets

Toray Industries is the first in the industry to use smart pallets equipped with active RFID tags developed by UPR Co., Ltd. Typically, pallets must be replaced with different pallets during transportation and storage to prevent their loss or outflow, and the loaded products must be reloaded each time. Smart pallets, on the other hand, do not need to be replaced, since the coming, going, and inventory of pallets can be managed from a distance with the embedded active RFID tags. Adoption of these smart pallets allows Toray’s products to go on the same pallet from production to storage, transportation, and use by the customer. This has eliminated cargo handling work by truck drivers and warehouse personnel, shortened loading and unloading time, improved the working environment, and increased logistics productivity. Moreover, the Company is reducing CO2 emissions related to pallet recovery by using its packaging materials recovery system to recover empty pallets.

Reducing the Environmental Impact of Distribution

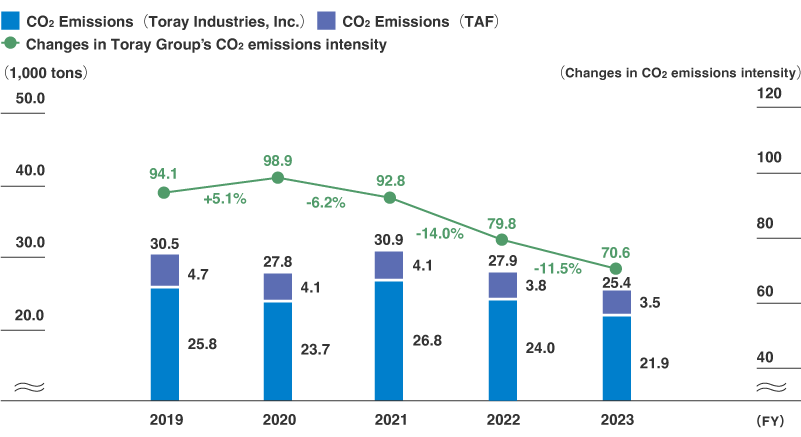

Reduction in CO2 emissions per unit of sales from distribution activities (year-on-year)

- ■Reporting scope

- Toray Group (Only specified consigners, Toray Industries, Inc., TAF)

- ■Target in fiscal 2023

- 1%

Result in fiscal 2023

11.5%

Toray Group is working hard to reduce CO2 emissions in transport. These initiatives include reducing transport distances, shifting modes of transport to those which have less environmental impact such as sea and rail (modal shift), and raising transportation efficiency.

In fiscal 2023, at Toray Group (only specified consigners2 in Japan), CO2 emissions from distribution activities3 were 25,400 tons, down 2,400 tons (8.7%) from the previous fiscal year, due primarily to a decrease in transport volume.

Due to an increase in net sales, which is the denominator, at Toray Industries and other group companies, CO2 emissions intensity4 decreased for Toray Group. With the fiscal 2014 level (set at 100) as the base, the change in the Group’s CO2 emissions intensity was 70.6 in fiscal 2023, representing a decrease of 11.5% from the previous fiscal year (fiscal 2022).

In fiscal 2023, Toray Industries’ CO2 emissions from distribution activities totaled 21,900 tons, down 114 tons from the previous fiscal year. This was primarily due to efforts for full-load transport, increased loading rates and modal shift achievement. In addition, transport volume fell for resin and film products in particular, resulting in an emissions decrease of 2,100 tons (8.9%) from the previous year.

Toray Industries’ CO2 emissions intensity from distribution activities decreased by 13.6% year on year (from fiscal 2022) because, CO2 emissions decreased, while net sales, the base unit denominator, increased. Over the past five years, however, CO2 emissions intensity decreased an average of 6.2% per year. As a result, Toray Industries is reliably meeting its legal mandate to reduce CO2 emissions intensity by an average of at least 1% every year.

Toray Group will continue to seek CO2 emissions reductions by pursuing environmentally responsible distribution.

- 2 Toray Industries, Inc. and Toray Advanced Film Co., Ltd., which have annual cargo transport totaling 30 million ton-kilometers or more, are “specified consigners” under Japanese law.

- 3 CO2 emissions from distribution activities refers to “CO2 emissions related to the transportation of cargo entrusted to freight carriers” stipulated in the Act on Rationalizing Energy Use (Revised Energy Conservation Act)

- 4 CO2 emissions from distribution activities ÷ the following transport-related indexes

Toray Industries, Inc.= Net sales

Toray Advanced Film Co., Ltd.(TAF) = Shipping volume

Specified consigners are required to endeavor to meet the legal mandate to reduce CO2 emissions intensity by an average of at least 1% every year over the medium- and long-term.

- Graph data revised:

Due to revisions made to TAF's CO2 emissions and CO2 emissions intensity figures from fiscal 2019 to fiscal 2022, the applicable figures in the graph for that period have also been corrected retroactively. - Notes:

1 Changes in Toray Group’s CO2 emissions intensity = Change in CO2 emissions intensity at each specified consigner group company × Each group company’s CO2 emissions / Total Toray Group CO2 emissions

2 Change in CO2 emissions intensity at each group company = CO2 emissions / Change in transport-related indexes (Fiscal 2014 = 100)

CO2 Reduction Through Modal Shift Promotion (Toray Industries, Inc.)

| Details of initiatives | CO2 Reduction (1,000 tons) |

|---|---|

| Full-load transport, and increased loading rates, etc. | 0.070 |

| Revision of inventory storage locations, and loading at the nearest port, etc. | 0.036 |

| Modal Shift | 0.008 |

| Total | 0.114 |

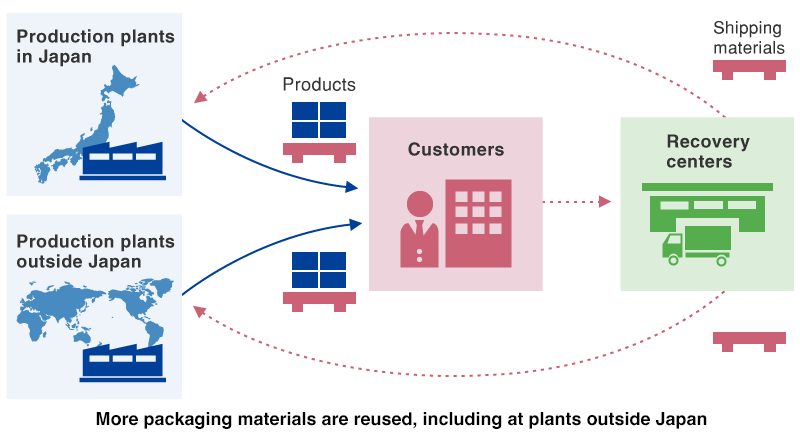

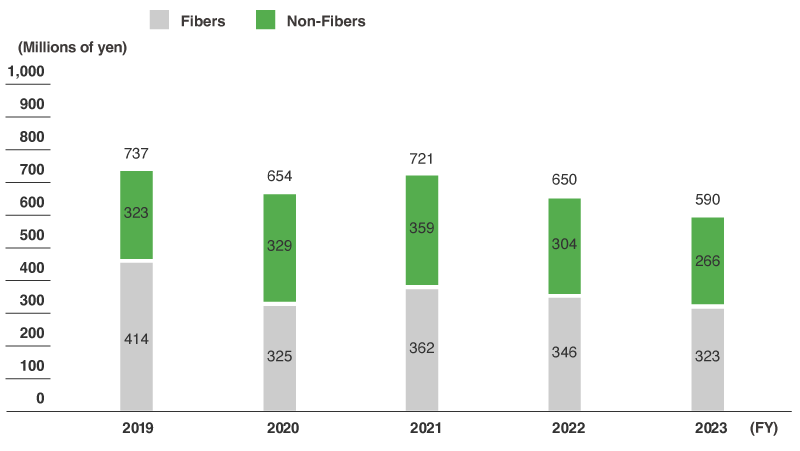

Expanding Collection and Reuse of Packaging Materials

Toray Group is establishing a global framework to collect and recycle packaging and shipping materials that are included with products used by customers.

The value of these materials collected by Toray Industries in fiscal 2023 was 590 million yen, a decrease of 60 million yen (9.2%) from the previous fiscal year.

The volume of the materials collected also decreased due to a drop in shipment volumes for fibers and films. In order to reduce the amount of new material purchasing, the Group internally shares information on the inventories of used shipping materials being collected, such as temporary inventories at collection centers.

Related Information

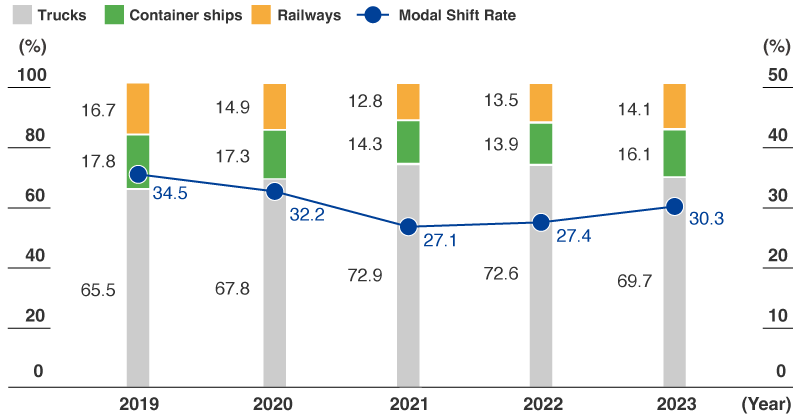

Promoting a Modal Shift

Toray Industries laid out its commitment to environmentally friendly distribution in its Basic Distribution Policies (Revised in March 2022), in which it aimed to balance consideration for the environment in the distribution process with better competition achieved by cost-cutting. Toward this end, the Company has actively pursued modal shift (switching from trucks to rail and ship transport). In addition, modal shift is also effective as a measure to address the recent vulnerabilities in truck transport caused by a shortage of drivers.

In 2023 (Jan – Dec), the modal shift rate increased by 2.9 points from the previous year to 30.3%, by actively investigating opportunities for switching from truck to rail transport and expanding the use of rail.

Toray Group will continue pursuing modal shift in diverse product and materials transport and will work more closely with distribution partners. Through these efforts, the Group will promote environmentally responsible distribution while taking into consideration the environmental impact of the distribution process.

Acquisition of Eco Rail Mark and Eco Ship Mark

Toray Industries has certified as an Eco Rail Mark Company by Japan's Ministry of Land, Infrastructure, Transport and Tourism and the Railway Freight Association. This recognizes Toray's active efforts to use rail freight transport, a relatively environmentally friendly means of transportation. The Company also obtained Eco Rail Mark Product certifications for its TORAY TETORON™ fiber and TORAYCON™ polybutylene terephthalate (PBT) resin. Moreover, in fiscal 2017 Toray Industries achieved the Eco Ship Mark certification related to its film products, which are difficult to ship by rail. This program recognizes companies that are switching to ship transport and use maritime transport, which has a low environmental impact, to a certain extent.

Minimizing Natural Disaster Risks

Key external inventory sites that have been assessed for natural disaster risk and have implemented measures to mitigate serious risks (%)

- ■Reporting scope

- Toray Industries, Inc.

- ■Target in fiscal 2023

- At least 60%

Result in fiscal 2023

59%

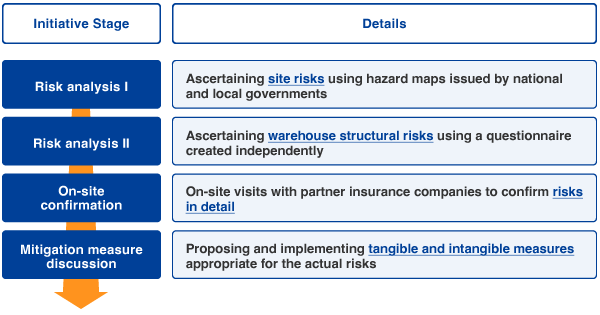

Toray Industries implements measures to prevent or minimize the damage caused by natural disasters such as typhoons and heavy rains, which have been increasing in frequency in recent years. It does this by continually investigating and identifying natural disaster risks at external warehouse sites in Japan, and by implementing response measures together with warehouse operators.

The Company ascertained the natural disaster risks at 68 main external warehouse sites. This was determined based on the structure of the warehouse buildings and the site environments, using tools such as hazard maps issued by the national and local governments. Some sites were determined to be at high risk, and on-site inspections were conducted. Based on the results of the investigation, mitigation measures were discussed with the warehouse operators and improvements are being made. Specifically, disaster prevention manuals were created based on flood risk information released by the Japan Meteorological Agency, while water gate barriers were prepared, the floor was leveled, and pallets were raised off of warehouse floors.

From fiscal 2021 to fiscal 2023, inspections were completed at 47 out of the 68 main warehouse sites. Of these, 28 sites were assessed as safe, while 19 sites were found to be at risk. Mitigation measures have been completed for 12 of the 19 sites at risk. As a result, 40 of the 68 sites (59%) are now either risk-free or have completed the appropriate mitigation measures. In fiscal 2024, further on-site inspections and discussions will be carried out to better mitigate risks.

Portable water dam (measure example)

Portable water dam (measure example) Pallets raised above the floor level (measure example)

Pallets raised above the floor level (measure example)

Initiatives to Improve Safety and Quality in Distribution

Toray Industries is working on a project to improve transport quality. The Company works with distribution partners to improve distribution quality and safety and to reduce the incidence of problems by sharing accident analysis data and distribution quality enhancement reports, conducting on-site inspections and holding quality control meetings with partners. Partners that make outstanding contributions to improving quality are recognized through annual awards5 These initiatives are aimed at reducing the number of problems such as those involving breakage, and reducing transport delays and incorrect shipments of Toray products.

- 5 Distribution-partner companies receiving awards in fiscal 2023 (alphabetical order):

Iyoshoun Inc., KUSUHARA Transportation Co., Ltd., Shikoku Meitetsu Transportation Co., Ltd., The Shibusawa Warehouse Co.,Ltd., Daisei Warehousing & Transportation Co., Ltd., Nagahama-Reizou, Fuji Logitech Holdings, Inc.

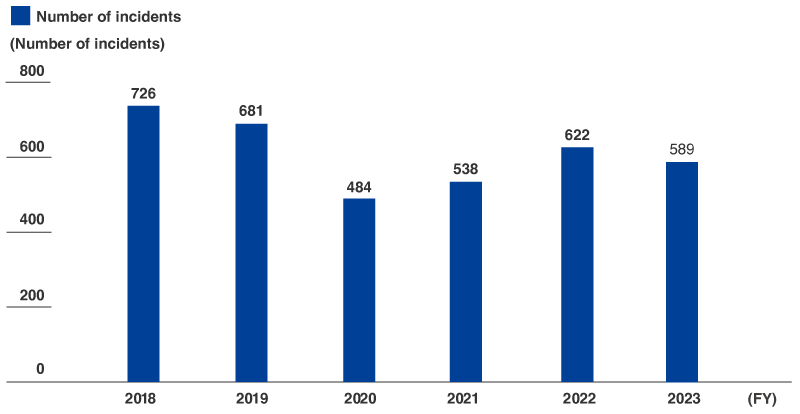

Distribution Incidents

Recently, logistics companies in Japan have experienced a labor shortage, and incidents such as product damage during transport have become more common.

Consequently, Toray Industries has seen an increase in product damage and misdelivery during transport on routes for smaller packages. In order to improve distribution quality, the Company approached distribution partners with high incident rates. Discussions were held on improvement measures, on-site visits were made, and educational activities were carried out. As a result, the number of distribution incidents in fiscal 2023 was 589, a reduction of 5% compared to the previous year. The Company will continue working with partner companies to improve distribution quality.

Legal Compliance and Safety Initiatives in Distribution

Logistics Efforts for Security Trade Control

In order to ensure thorough compliance with security trade controls relating to the export of its products, Toray Industries provides ongoing security trade control training to external warehouses where regulated items are stored. In fiscal 2023, in addition to explaining security trade control measures to seven sites belonging to six companies, important points were highlighted regarding the handling of regulated items, based on past near-miss incidents. Through this training, Toray once again stressed the importance of managing and handling regulated products appropriately.

Recommending that Distribution Partners Acquire Third Party Certification

Toray Industries recommends that its distribution partner acquire external certifications such as ISO 9001, ISO 14001, Green Management Certification6 and G Mark7. These certifications require companies to achieve legal compliance, improve quality, and practice environmental conservation in distribution processes. Toray Industries also pursues CSR initiatives in collaboration with distribution partners.

- 6 Green Management Certification: Certification is awarded by the Foundation for Promoting Personal Mobility and Ecological Transportation to companies that demonstrate a certain level of environmental improvement activities based on a manual for implementing green management (business management with a low environmental impact)

- 7 G Mark: A system that recognizes companies that meet certain criteria and demonstrate excellent safety, based on an assessment by the Safety Evaluation Committee established by the Japan Trucking Association of proactive initiatives for legal compliance and safety recommended by the Ministry of Land, Infrastructure, Transport and Tourism

Yellow Card Emergency Response Measures

Drivers of shipping vehicles carry a yellow card8 detailing emergency measures to be taken to minimize damage in the event of an accident. Toray Industries has also established an emergency communication system and carries out emergency training. In the unlikely event of such an accident, the Company has procedures in place enabling the necessary staff to be dispatched as swiftly as possible to the accident site for assistance.

- 8 A yellow card: A card listing the names of any hazardous substances, applicable laws and regulations, hazardous properties, procedures in case of accident, emergency reporting and contact information, methods for minimizing the spread of damage, and other relevant information.

Initiatives to Prevent Overloading

The overloading of trucks causes vibration, noise, damage to roads and facilities, and also creates driving hazards. Consequently, Toray Industries is putting considerable effort into the prevention of overloading.

Compliance and Security Measures for Importing and Exporting

As a measure to ensure the legality and safety of imports and exports as part of Toray Group's expanding global operations, a US subsidiary of Toray International, Inc. enrolled in the Customs-Trade Partnership Against Terrorism (C-TPAT)9 with the aim of strengthening global supply chain compliance. In order to realize more efficient imports and exports of materials and to strengthen supply chain compliance and security measures, Toray Group is also encouraging its worldwide distribution partners to obtain Authorized Economic Operator (AEO)10 status.

- 9 C-TPAT: A voluntary program introduced by United States Customs and Border Protection in November 2004. The aim of the program is to ensure and strengthen security through the global supply chain, based on international cooperation with private operators importing goods into the US.

- 10 AEO: A status implemented by the EU in December 2006 that gives priority in customs procedures to importers and exporters with a high level of compliance for cargo security. The Japanese Customs Act was also revised in 2007, and a similar qualification system was established to provide priority in customs procedures to highly compliant operators.

Two-Star Certification From a Driver-Friendly Workplace Program [Toyo Logistics Co., Ltd. (TLS)]

Driver-Friendly Workplace Certificate

Driver-Friendly Workplace Certificate

In February 2022, TLS obtained a one-star certification as a Certified Excellent Workplace for Drivers and in 2023, achieved a two-star certification for all of its transport business sites.

This program was established by the Ministry of Land, Infrastructure, Transport and Tourism as part of a comprehensive initiative to address the shortage of drivers in the road transport industry, in collaboration with the Ministry of Health, Labour and Welfare. The goal is to promote recruitment at certified businesses. Moreover, being publicly listed as a driver-friendly workplace on the program website enhances confidence in certified company among its business partners.

To obtain certification, businesses must meet benchmark scores in categories such as working hours and days off for truck drivers, physical and mental health measures, safety and security, and efforts to recruit and train diverse personnel.

TLS is committed to further improving its work environments and is striving to achieve three-star certification.

Click here for the main initiatives for CSR Guideline 9, “Establishing Sustainable Supply Chain” in CSR Roadmap 2025.