- HOME

- Sustainability

- Contributing Solutions to Social Issues through Business Activities

- Approach to Green Innovation Products

CSR Activity Report (CSR Guideline Activity Reports) - Contributing Solutions to Social Issues through Business Activities

Approach to Green Innovation Products

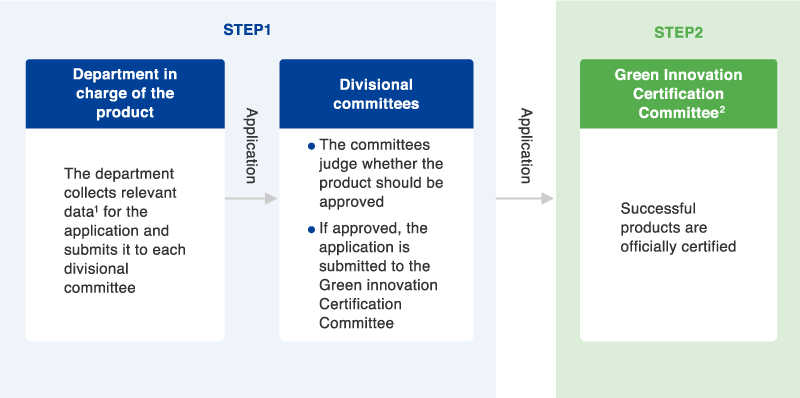

The following diagram outlines Toray Group's process and procedures up until fiscal 2022 for certifying Green Innovation products. Products were subjected to a two-stage screening process conducted by the divisional committees and by the group-wide Green Innovation Certification Committee. Those able to demonstrate objective evidence of providing an effective solution for global environmental issues were certified as Green Innovation products.

As of fiscal 2023, Green Innovation and Life Innovation products have been combined and renamed Sustainability Innovation (SI) products. These are screened by the Sustainability Innovation Certifying Committee (tentative name), which maintains the same certifying system as was used for Green Innovation products.

- 1 This includes LCA data, T-E2A data, and estimates of CO2 emissions reduction attributable to the product.

- 2 Comprised of members of Toray Industries' Global Environment Business Strategic Planning Department, Corporate Marketing Planning Department, and Technology Center Planning Department, as well as experts when necessary.

Green Innovation-Related Products and R&D Announced in Fiscal 2022

Toray to Domestically Sell Chemical Recycled Fiber Products Derived from Fishing Nets

Expansion of Recovery and Recycling Systems in Japan

Discarded fishing nets

Discarded fishing nets

Toray Industries plans to begin selling nylon 6 chemically recycled fiber (N6CR) yarns, textiles, and other products in Japan. These offerings apply Toray’s depolymerization and repolymerization technology3 to recycled plastics and other materials that Refineverse Group, Inc., makes from recovered fishing nets.

This year, the Company set up a new production system at its Nagoya Plant that identifies virgin raw materials from fossil sources. This setup comprises a raw materials input facility for recycled fishing net-derived resin and recycled lactam storage tanks. This setup will recycle nylon 6 fiber products, accelerate efforts to develop an advanced fiber to fiber recycling business, and contributing to a circular economy.

Toray’s new N6CR facility will enable it to overcome technical challenges and reinforce its range of high-performance, high-value-added nylon fibers for apparel. The company looks particularly to expand sales of thin, eco-friendly fabrics for sports and outdoor wear, innerwear, and legwear.

Common applications for industrial nylon fiber are automotive parts, ropes, fishing nets, carpets, and other general industrial materials. Toray’s endeavor will help cut environmental impacts across an array of industrial fields and drive uptakes of sustainable resources.

Toray Industries will expand its advanced fiber to fiber recycling business by collaborating with customers in initiatives to sell products incorporating its N6CR materials.

- 3 Depolymerization and repolymerization is a process involving the initial breakdown of a polymer into its individual monomer units and removal of any impurities, followed by polymerization of the new monomers to create a new polymer.

Toray Invents 100% Bio-Based Adipic Acid from Sugars Derived from Inedible Biomass, Scaling Up for Application to Eco-Friendly Nylon 66

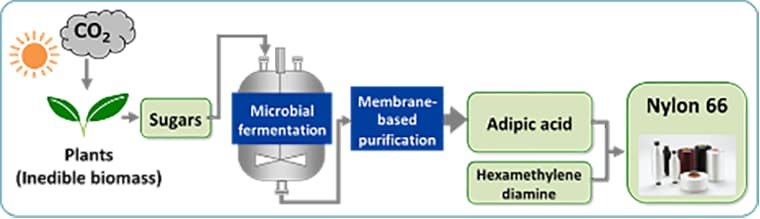

Toray Industries has developed the world’s first 100% bio-based adipic acid, a raw material for nylon 66 (polyamide 66), from sugars derived from inedible biomass. This achievement came from using a proprietary synthesis technique combining the company’s microbial fermentation technology and chemical purification technology that harnesses the power of separation membranes.

The Company has started to scale up this process. It will conduct polymerization trials, develop production technology, and conduct market research to commercialize nylon 66 applications by around 2030.

Nylon 66 has been used for many years in fibers, resins, and other applications due to its exceptionally durable, strong, and rigid properties. However, there has been increasing pressure to develop eco-friendly nylon 66. One challenge is that conventional chemical synthesis for producing adipic acid, the raw material of nylon 66, generates a greenhouse gas called dinitrogen monoxide.

Toray Industries was the first in the world to discover microorganisms that produce an adipic acid intermediate from sugars. The company reconfigured metabolic pathways within microorganisms to enhance production efficiency by applying genetic engineering technology, which artificially recombines genes to streamline synthesis in microorganisms. It also employed bioinformatics technologies to design optimal microbial fermentation pathways for synthesis. Quantity of the intermediate synthesized by microorganisms has increased more than 1,000-fold since the initial discovery, and the efficiency of synthesis has improved dramatically.

The Company is using reverse osmosis separation membranes to concentrate the intermediate in the purification process. This approach is more energy efficient than other methods that do not use these membranes.

This bio-adipic acid production technique is free of dinitrogen monoxide emissions, unlike the manufacturing processes for petroleum-derived adipic acid, and is expected to help combat global warming.

Toray’s achievement is partly based on funding from the New Energy and Industrial Technology Development Organization (NEDO), Japan’s national research and development agency.

Toray Creates Membrane Separators to Recover Lithium from End-of-Life Lithium-Ion Batteries.

A new highly lithium-selective nanofiltration membrane vastly improves acid resistance.

Lithium recovery from end-of-life lithium-ion batteries

Lithium recovery from end-of-life lithium-ion batteries Lithium separation using nanofiltration membranes

Lithium separation using nanofiltration membranes

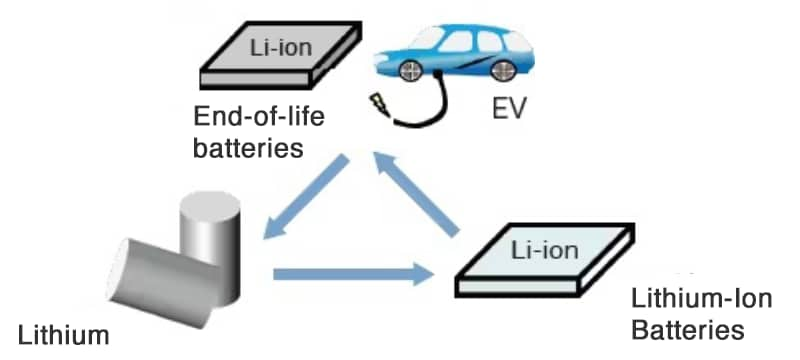

Toray Industries has created a new nanofiltration membrane to recover lithium from end-of-life (EOL) automotive lithium-ion batteries (LIBs) which are expected to be generated in large quantities in the future and are currently largely disposed of. The Company is already starting to evaluate recovery using actual leachate from EOL LIBs and will accelerate research and technological development to commercialize its approach.

Demand for lithium resources should surge with electric vehicle uptake. The challenge with the mainstream evaporation pond process4 for lithium production is that the number of high-output locations is limited. The alternative to this is the ore process5 which has issues with its lengthy production process and high-temperature heat treatment, generating high carbon dioxide emissions and increased costs which could drive lithium-ion battery prices even higher.

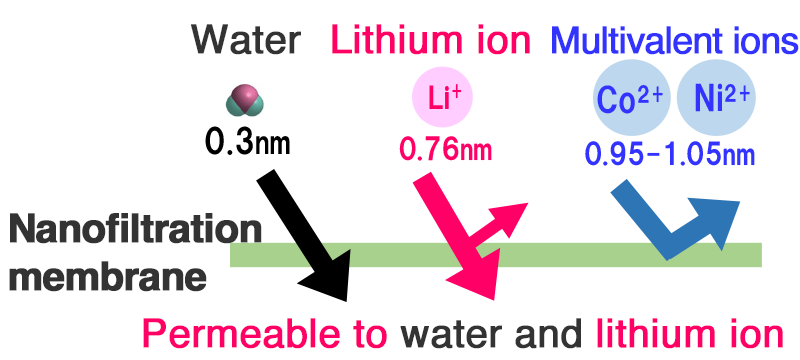

Nanofiltration membranes can selectively separate dissolved multivalent ions and organic matter. Prime uses of these membranes are to filter ground and river water hardness and agricultural chemicals. They also desalinate and purify in food and biotechnology applications. One downside of conventional nanofiltration membranes is their vulnerability to highly acidic solutions, limiting their application to neutral solutions. Another is insufficient selectivity for multivalent ions, hampering separation efficiency. Prevailing membranes thus cannot be used to recover valuable metals from potent acid EOL LIB leachates.

Toray Industries created a new cross-linked polymer membrane with high acid resistance and a precision pore structure smaller than 1 nanometer. This success is the result of using organic synthesis, polymer chemistry, and nanotechnology after analyzing membrane degradation by acids and optimal membrane pore structures for selective separation. The acid-resistance of this membrane is around five-fold higher than conventional offerings, with the selectivity being 50% greater.

Toray’s technology will streamline the recovery of valuable metals and make it possible to recover high-purity lithium in high yields. Carbon dioxide emissions from recovering 1kg of lithium compound using Toray’s nanofiltration membrane process are nearly two-thirds lower than from the ore process.

Going forward, the Company will collaborate with automakers, battery and battery material manufacturers, recyclers, and other partners to establish a lithium recycling process. Toray Industries stands to help realize a carbon-neutral economy by eliminating the shortages of lithium that will become a significant concern amid the penetration of electric vehicles.

- 4 Evaporation pond process: Lithium compounds are produced by pumping brine from a salt lake, concentrating it under the sun for six to twelve months, and refining it.

- 5 The ore process: Lithium compounds are produced by dressing, roasting, leaching, and refining ore after mining.

Click here for the main initiatives for CSR Guideline 7, “Contributing Solutions to Social Issues through Business Activities” in CSR Roadmap 2022.