- HOME

- Investor Relations

- Annual Report

- Feature: IR Seminar on Toray Group’s Environmental Initiatives

Feature: IR Seminar on Toray Group’s

Environmental Initiatives

On July 15, 2022, Toray Group held an investor relations seminar titled “Toray Group Initiatives for Global Environmental Issues,” with lectures presented by Koichi Abe, Executive Vice President, and Toshiyuki Nonaka, General Manager on Special Assignment, Global Environment Business Strategic Planning Department.

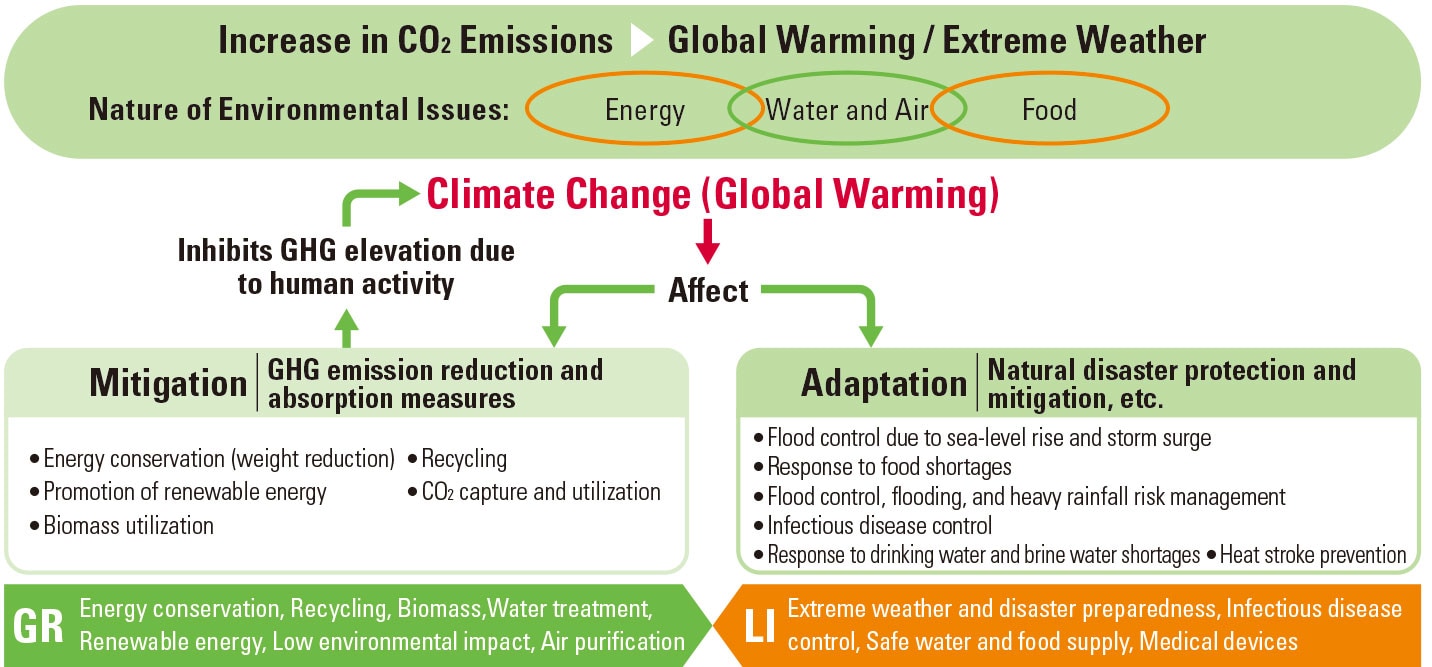

Koichi Abe Executive Vice President

Toray Group views global environmental issues as consequences of energy, water and air, and food, and therefore engages in R&D from the two approaches: “mitigation measures” and “adaptive measures”. Mitigation measures seek to reduce GHG emissions as the fundamental cause of these problems, and adaptive measures seek to manage the impacts that are already occurring or that cannot be avoided. Global environmental issues are assumed to be critical challenges for both the Green Innovation Business Expansion Project (GR Project) and the Life Innovation Business Expansion Project (LI Project). In terms of the impact of Toray Group’s environmental contributions, I believe that technologies involved in “weight reduction” and “membrane separation” are attracting interest, which is why I would like to focus my talk on these.

Carbon Fibers Find Success Beyond Aircraft

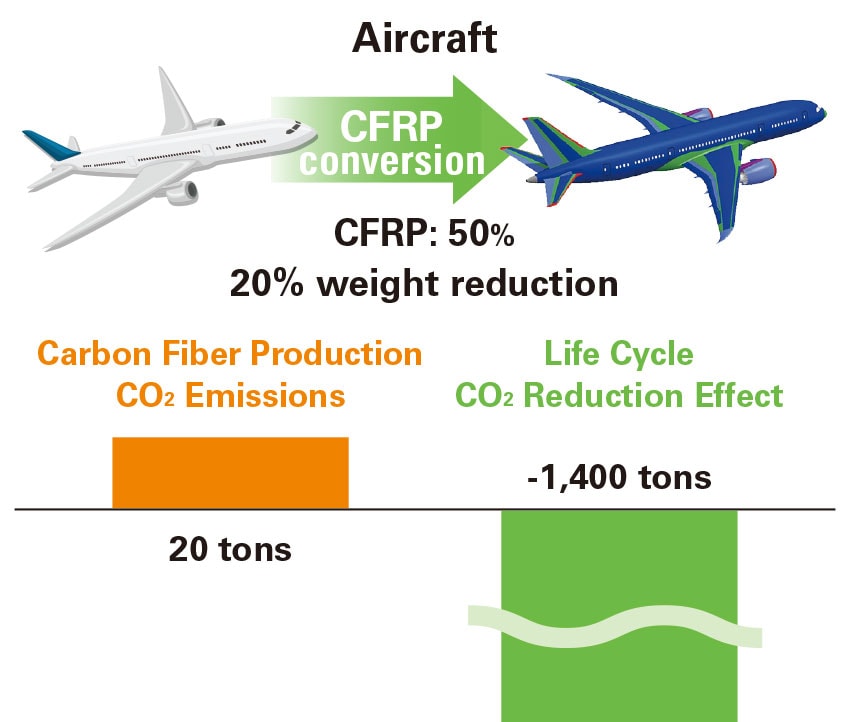

The first technology I would like to cover on the topic of “weight reduction” is of course carbon fibers, for which Toray holds one of the highest shares in the world. Given that they are ten times stronger than steel and a quarter of the weight without rusting, carbon fibers are used in products ranging from aircraft to automobiles, wind turbines, and fishing rods. This material particularly had a large impact on improving the fuel efficiency of aircraft.

Although the synthesis and carbonization processes do emit 20 tons of CO2 per a ton of carbon fiber, using carbon fiber reinforced plastics (CFRP), a composite material made from carbon fiber and resin, for 50% of an aircraft body structure by weight is expected to reduce 1,400 tons of CO2 emissions over the aircraft’s life cycle.

CFRP is also becoming an indispensable material for wind power generation. In 2015, wind power generation typically used 60-meter-long glass fiber composite blades.

As the longer the wind blades, the higher power generation efficiency, 120-meter-long blades are expected to become the mainstay by around 2030. However, in proportion to their length, the blades require strength to withstand strong winds and rigidity to avoid bending under their own weight. Therefore, all blades exceeding 90 meters in length are increasingly being made of CFRP, and expectations on Toray’s technological capabilities from wind power generation is also raising.

Carbon Fiber Association Model Cooperation: Prof. Takahashi and Prof. Li Jia, The University of Tokyo, All Nippon Airways, The Boeing Company (U.S.)

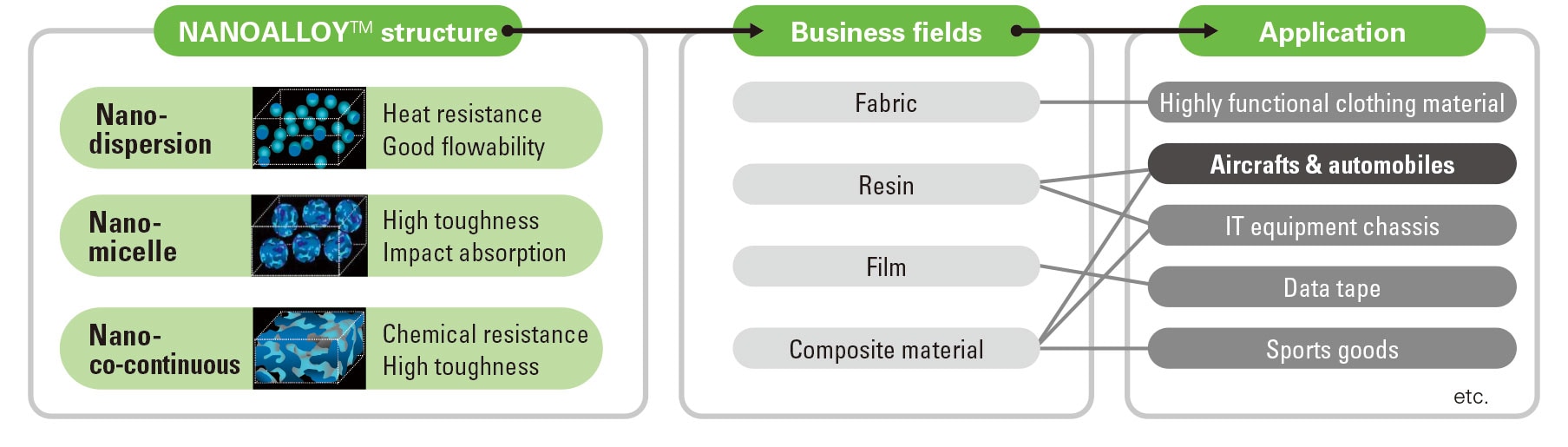

Future of Promising NANOALLOY™

Approaches to reducing weight typically rely on concepts of replacing metals with plastics, so in this respect, NANOALLOY™, a microstructure control technology for which Toray holds a patent, has become an extremely promising approach. This technology mixes several different polymers at the nanoscale (one-billionth of a meter) to form alloy structures, which enable polymer materials to exhibit a higher level of performance and function that could not have been realized using conventional alloys formed at the micron scale (one-millionth of a meter). In fact, Toray has used this technology to develop a special plastic that softens like rubber when subject to impact, which is increasingly being adopted for impact-absorbing automobile parts.

Seawater Desalination Technology Supplies Fresh Water for 730 million People

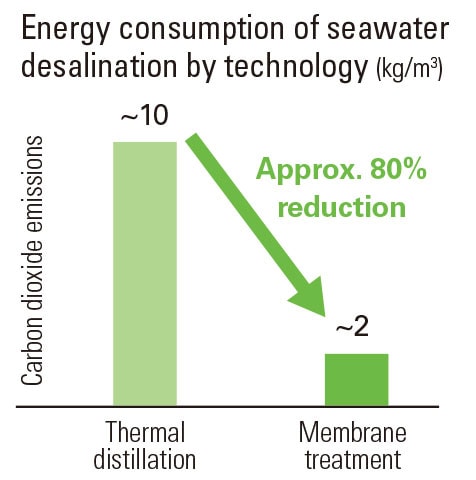

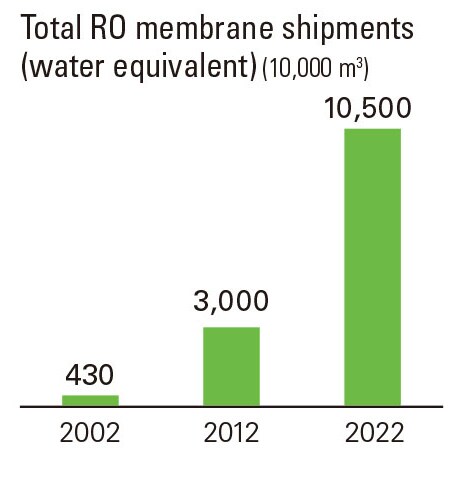

In 1968, Toray began developing reverse osmosis (RO) membranes to convert seawater into fresh water. Although these membranes are commonly used in seawater desalination plants in the Middle East today, with its abundant energy resources, early on this region typically used evaporation methods that boil and distill seawater, meaning there was absolutely no need to remove salt from seawater using membrane treatments. For this reason, Toray originally focused its efforts on the ultra-pure water filters required for semiconductor manufacturing for a time in order to perfect its water treatment technologies. Later on, as the demand for water expanded with global population growth and economic development in emerging countries, water resource shortages caused by global warming-triggered droughts and industrialization-triggered water pollution became aggravated. Against this backdrop, Toray’s membrane treatment methods began to attract interest because of their ability to control water quality with high precision and treat water at high speeds. Compared with evaporation methods, membrane treatment methods also reduce energy consumption and desalination costs, which has led to a dramatic increase in shipment volumes for Toray’s reverse osmosis membranes over the past ten years. In fact, these have already been delivered to more than 100 large-scale desalination plants in 99 countries around the world, which have helped supply fresh water to 730 million people globally when converted to water volume.

Further Evolution of Separation Membrane Technology

With more than 50 years of history, separation membrane technologies have also come into the limelight for producing green hydrogen in a way that does not emit CO2.

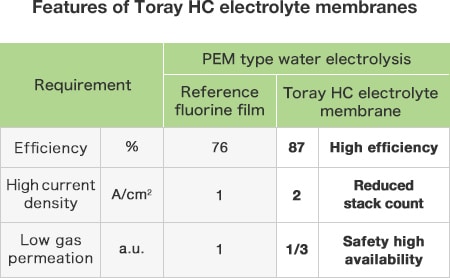

Toray has been participating in a NEDO project intended to produce hydrogen from water through electrolysis using power sourced from renewable energy. The water electrolysis method adopted for this project uses a polymer electrolyte membrane (PEM). For more than 15 years now, Toray has been involved in developing hydrocarbon (HC) electrolyte membranes that can be effectively applied in PEMs for use in fuel cell vehicles. And these membranes have been well-received for their ability to produce twice as much hydrogen per area of membrane compared with conventional fluorine membranes at the same voltage.

More recently, Toray applied its water treatment membrane technology to develop a polymeric separation membrane module that selectively permeates hydrogen at high efficiency from mixed gases containing hydrogen. At 98%, these modules have achieved the world’s highest level of permeated hydrogen purity. This technology is able to improve hydrogen purity in a single separation pass to a level that previously required multiple filtration passes.

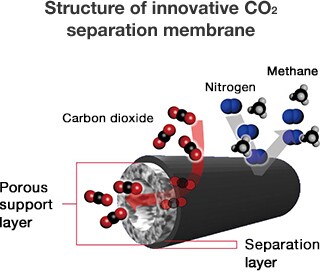

Moreover, Toray also combined its carbon fibers and membrane separation technologies to develop a revolutionary CO2 separation membrane made from porous carbon fibers that can separate and recover CO2 from factory emissions, for example. The Company will begin demonstration tests for specific applications in 2025, and is moving forward with efforts for real-world operations in 2030.

Pioneering the Development of Biomaterials

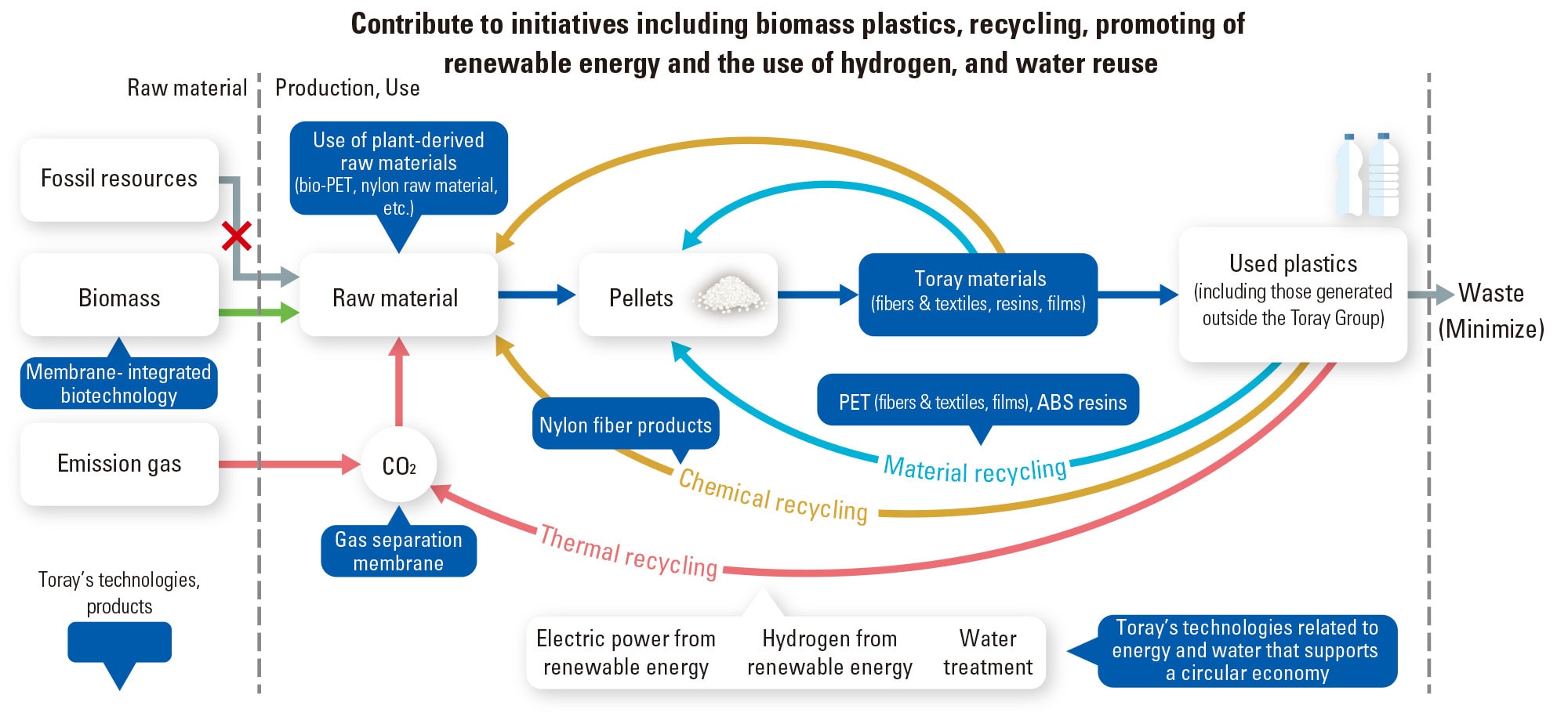

Toray is also accelerating efforts to produce valuable materials from nonedible biomass in a way that does not conflict with food issues. Specifically, the Company mass produces partially bio-based PET fibers from ethylene glycol raw materials produced from nonedible sugar cane molasses. These fibers have been used to produce nonwoven material created using ultra-fine fibers, for example. With a focus on sportswear and automotive interiors, Toray also aims to mass produce the world’s first 100% bio-based PET at the earliest possible timing using raw materials such as plant-based ethylene glycol and bio-para xylene. Moreover, Toray developed a membrane bioprocess that fuses its water treatment separation membrane technologies and biotechnologies. At a demonstration plant in the Kingdom of Thailand, one of the world’s largest producers of sugar cane, the Company is currently conducting pilot operations for efficient co-current production of cellulosic sugar, polyphenol, oligosaccharide, and other materials made from bagasse, which are byproducts from residue left after extraction of juice from sugarcane.

Technological Fusion Drives Innovation

As you can see from the examples of carbon fibers and water treatment, Toray’s R&D features “long-term continuity” in a way that persistently engages in recognizing the value of materials. In addition, Toray has centralized all of its R&D functions deployed in various fields within the Technology Center, where an undivided R&D organization that allows for technological fusion to easily emerge has also become one of its major strengths. Toray believes that fundamental solutions for global environmental issues are inconceivable without innovations in materials, and therefore promotes the drive for innovation through technological fusion on a group-wide basis.

Toshiyuki Nonaka General Manager on Special Assignment, Global Environment Business Strategic Planning Department

Behind the SDGs lies the concept of planetary boundaries. On the one hand, human lifestyles have become materially rich and convenient through economic growth and technological development, on the other hand, climate change, biosphere integrity, land use changes, and biogeochemical cycles have become major topics of discussion given the indication that these have reached a level that exceeds the range in which humans can safely act.

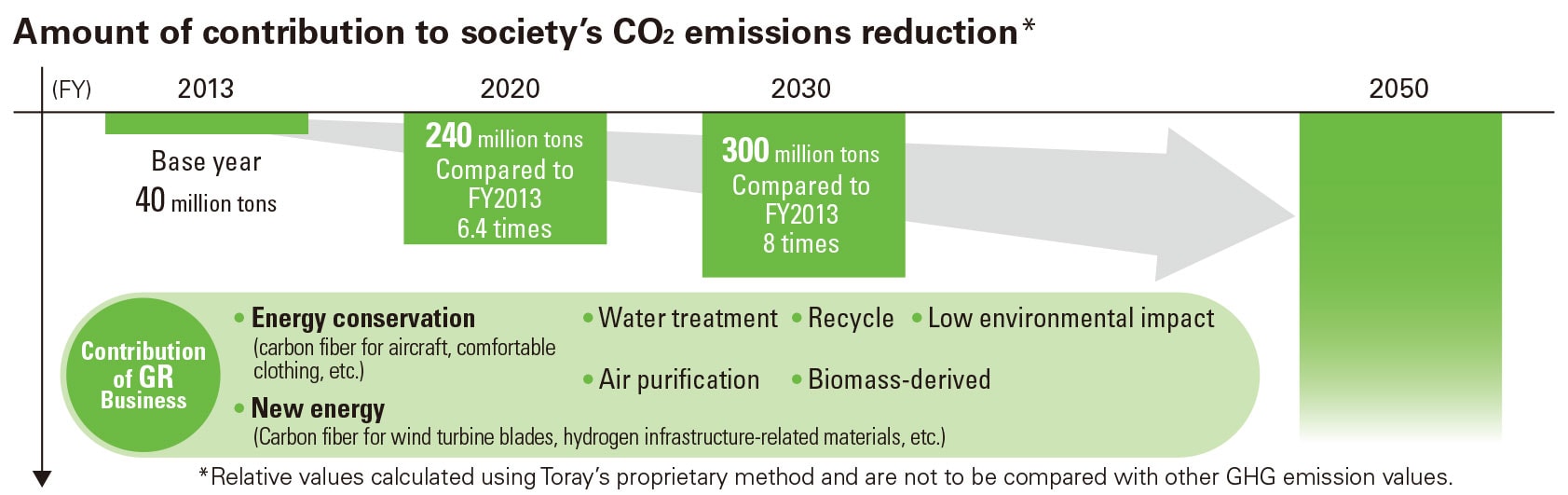

Against this backdrop, today it looks as though debate will also heat up over disclosing environmental contributions brought about through products and services, which can be considered Scope 4 following on Scope 1, 2, and 3. In this respect, Toray already visualizes its environmental contributions through a proprietary calculation method and engages in various projects with targets set to be achieved by fiscal 2030.

Therefore, I would like to focus my talk on three of the four visions for the world for which Toray Group aims to achieve by 2050 under the Toray Group Sustainability Vision. At the same time, I will cover Toray Group’s business strategies for ensuring coexistence between business growth and solutions to environmental issues.

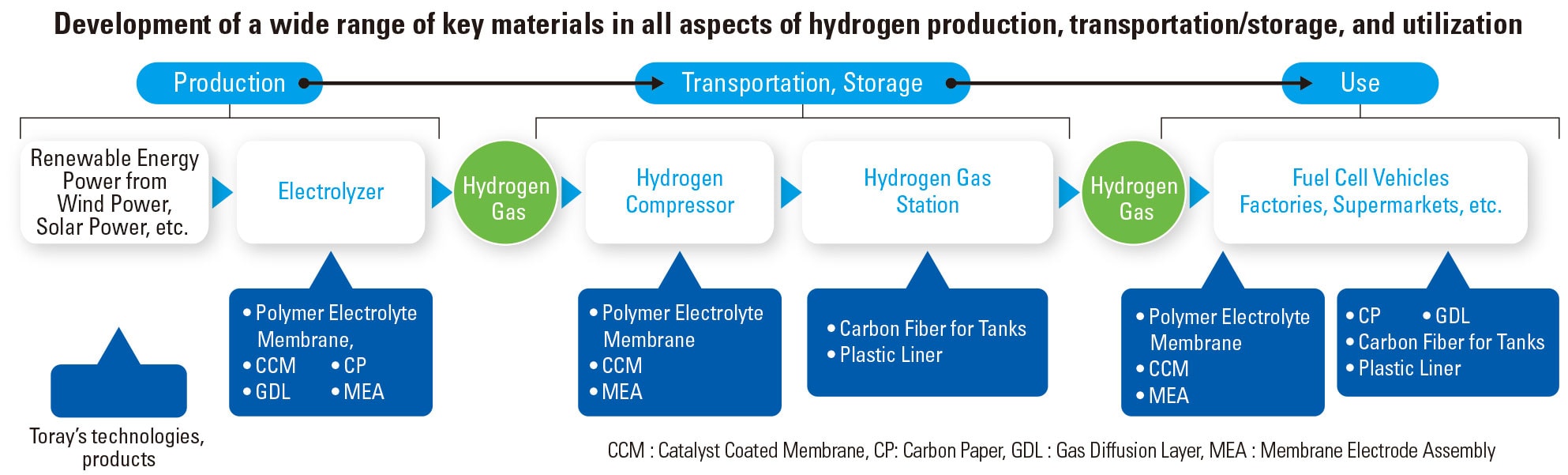

Developing a Broad Range of Core Materials for the Hydrogen Value Chain

As one of the visions for the world for which the Group aims under the Toray Group Sustainability Vision, "A net zero emissions world, where greenhouse gas emissions are completely offset by absorption" refers to carbon neutrality.

However, this vision requires the realization of a hydrogen society that eliminates CO2 emissions from combustion as well, which is why Toray engages in the development of a broad range of core materials for each of the hydrogen production, transport, storage, and usage stages.

For example, high-strength carbon fibers and plastic liners are used in hydrogen storage tanks, so in preparation for market expansion, one of the group’s subsidiaries in Germany has been augmenting production facilities for catalyst coated membranes (CCM) and membrane electrode assemblies (MEA), both of which are key components of hydrogen fuel cells. Moreover, Toray received the cooperation of Hitachi Zosen Corporation in developing a megawatt class PEM water electrolysis unit for a P2G (Power to Gas) system that produces green hydrogen using renewable energy. This P2G system has already begun delivering green hydrogen to factories and supermarkets in Yamanashi Prefecture, Japan. In addition, a consortium consisting in part of Yamanashi Prefecture and Tokyo Electric Power Company Holdings is advancing a large-scale P2G system project, which plans to put a large-scale 16-megawatt class water electrolysis unit using Toray’s hydrocarbon (HC)-type electrolyte membranes into real-world operations by fiscal 2025.

Moreover, Toray has acquired a 25% stake in Yamanashi Hydrogen Company, Inc., Japan’s first P2G service company. In addition, Toray developed a smallscale P2G system package, and has launched an alliance business that aims to use this package in decarbonizing manufacturing and other industries that are difficult to electrify. Meanwhile, in order to advance technology creation for green hydrogen production and global deployment together with Siemens Energy AG, Toray has entered into a strategic partnership with this company.

Building a Circular Resource Use Model

As the second vision, “A world where resources are sustainably managed” focuses on material recycling for reusing fibers and textiles, resins, films, and other plastics products. In addition, chemical recycling, which converts unrecyclable plastics back into basic chemicals such as monomers and gases, is already implemented for nylon fiber/textile products. In terms of thermal recycling, which recovers and utilizes heat energy generated during the incineration process, Toray has succeeded in developing a technology that separates and recovers CO2, as the Vice President Abe touched upon earlier.

Promoting the Recycled Fiber and Textile &+™ Business

Toray has a long history in recycling fibers and textiles, in particular, and in 2002 established the Fibers & Textiles Recycling Department. Along with expanding material recycling as an ongoing effort and chemical recycling for Nylon 6 products, the Company unified its fibers and textiles business recycling activities. As an effort that without question exemplifies long-term continuity, in 2019 Toray launched the &+™ recycled fiber and textile brand of products made using recovered PET bottles as raw materials. Combining high whiteness, high reliability based on traceability technology, and high purity, these products have already been adopted by Seven & i Holdings Co., Ltd., MARUI GROUP CO., LTD., and others. Moreover, the Company has undertaken the challenge of applying chemical recycling for materials that are difficult to regenerate using material recycling, such as those containing dyes and other additives that are difficult to remove, blended materials that are difficult to separate out, and those for which repeated recycling causes deterioration.

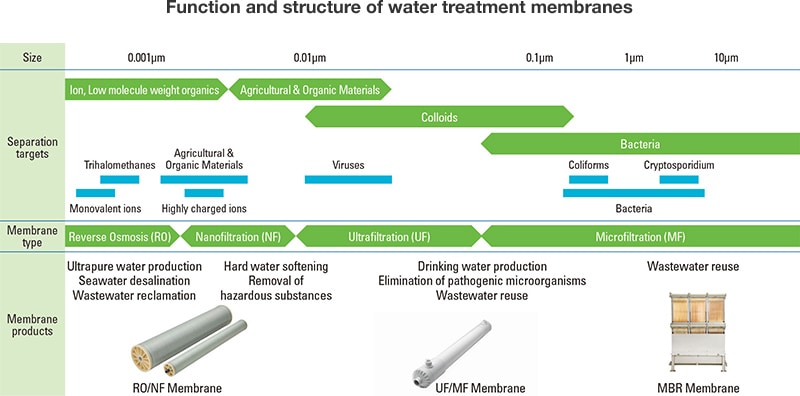

Global Leader in Water Problem Solutions

As the third vision, “A world with a restored natural environment, with clean water and air for everyone" is something that might be difficult to experience first-hand in Japan. But looking to the world beyond, water shortages are becoming increasingly problematic with continuous population growth, even in places where large populations were never meant to exist, coupled with the advance of global warming. In response, Toray’s membrane treatment technologies that realize high-quality, high-speed, energy-saving treatment processes can be considered an essential technology for the 21st century. Toray has established itself as the global leader and top technology share holder for reverse osmosis (RO) membranes, which are able to separate out the smallest substances, yet are a difficult technology to work with. In addition, the Company possesses all four types of membrane technologies, namely RO membranes, nanofiltration (NF) membranes, ultrafiltration (UF) membranes, and microfiltration (MF) membranes. And from the perspective of being able to separate out various substances, Toray is likely the only company with this capability, and will aim to maintain its position as the global leader in water treatment problem solutions.

Purifying Air with Air Filters

In addition to water, Toray realizes high-quality air environments by adsorbing contamination from the air using low-pressure loss, high dust collection efficiency air filters made from high-performance, nonwoven sheet made of special ultra-fine polypropylene fibers that are given electret properties through a specialized process. Substances that permanently maintain electric polarization even without an external electric field, and that produce an electric field of their own, are called electrets. Toray’s nonwoven fabrics are made from ultra-fine fibers of approximately two microns in width, where each individual fiber is provided with an advanced electret function. This approach provides its nonwoven fabrics with a high trapping efficiency for PM2.5, viruses, and other particles, as well as offensive odors. Sold under the TORAYMICRONTM name, these nonwoven fabrics have been proposed as filter materials that help broadly improve air quality and conserve energy in a wide range of applications, for everything from home-use to industrial-use.

Transforming Nature Positive into Opportunity

As interest in global environmental issues dramatically increases, following upon carbon neutrality, nature positive, which aims to stop the world from damaging biodiversity and other forms of natural capital so that they can recover, is coming to be viewed as a global objective. Like the TCFD, this concept led to the launch of the Taskforce on Nature-related Financial Disclosures (TNFD) in June 2021. Although the world now also focuses on biodiversity, Toray has committed itself for many years to water and air, so I feel the times have finally caught up to us. Nature positive covers the three areas: food, land and ocean use; infrastructure and construction; energy and extraction activities. Therefore, it is expected to create a market with an annual value of $10.1 trillion. For this reason, Toray views carbon neutrality, circular economy, and now nature positive as major business opportunities, and aims to ensure its presence in these areas through innovative material technologies.