- HOME

- Investor Relations

- Annual Report

- Special Feature: Value Creation

Special Feature: Value Creation

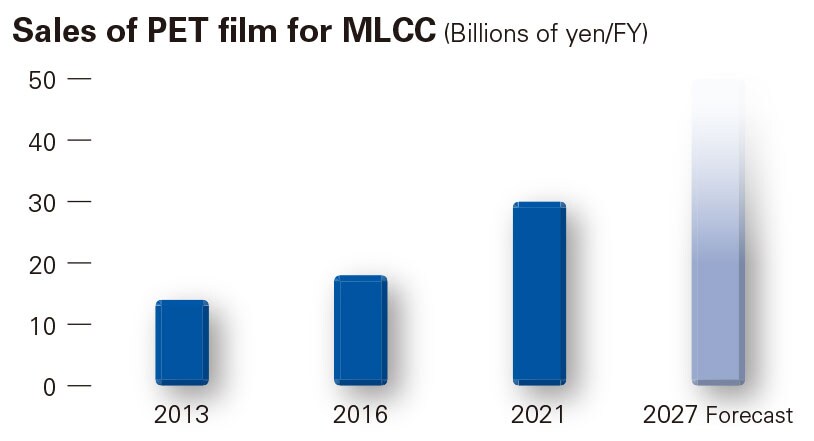

Co-creation with customers has enabled Toray to refine PET films, which significantly impact the performance and quality of multilayer ceramic capacitors (MLCCs), items essential for electronic circuits. In addition, Toray has established the industry’s first recycling system to contribute to customers’ circular economy.

Innovative Technologies That Expand Applications

through the Ages

MLCCs are incorporated into various electronic circuits to eliminate noise from radio waves and stabilize power supply. MLCCs have become smaller, down to just a few hundred microns, along with the miniaturization of semiconductor devices and substrates, with roughly 800 used in a single smartphone, 1,400 in a PC, and 5,000 in an automobile.

Toray PET (polyethylene terephthalate) film Lumirror™ boasts the world’s No. 1 market share as a release film used in MLCC production.

Toray was the first company in Japan to commercialize PET films with the release of Lumirror™ in 1959. Back then, PET films were mainly used for food packaging and labels, and there was no need to be concerned about the finely shaped surfaces.

Later on, upgrading of functionality in PET films accelerated, as demand grew for its use as base film for magnetic tapes such as VHS and cassette tapes. This is because a smooth film was required to suppress noise and degradation for magnetic tapes, which are recording media with magnetic material applied to the surface of the film. In response, Toray developed the thin-film lamination technology (NEST*), which controls the smoothness and friction of film surfaces, enabling Toray to gain a large share of the magnetic tape market.

The market for these magnetic tapes was eventually replaced by DVDs, yet Toray PET films, combined with its nano-level controlled processing and production technology, have evolved into a very effective film for making the ceramic layer of MLCCs thinner and without irregularities. In addition, through co-creation with a major MLCC manufacturer, we have realized a system for collecting and reusing used PET films.

- New Surface Topography (NEST): A technology that uses a thin layer of polymer containing particles on a surface to align the particles in a row and align the height of the protrusions.

Mutual Collaboration among R&D, Sales & Marketing,

and Production

R&D

R&D

Atsushi Matsunaga General Manager, Gifu Film Technical Department

Toray PET films are used as a support and release film in the production processes for MLCC, which are manufactured through the layering of hundreds to thousands of ceramic insulation layers.

In recent years, there has been a noticeable trend toward thinner and increasingly laminated ceramic layers to meet the need for smaller and higher capacity MLCCs, mainly for mobile devices, and even the slightest defect in the film can significantly affect the performance and yield of MLCCs. To that end, there are major advantages to our unique technologies starting with NEST, which controls the structure of film surfaces based on its track record of excellence in magnetic tape materials. Specifically, NEST is highly regarded for its ability to achieve both smooth surfaces and process suitability through co-extrusion and lamination technologies that form uniform surfaces, design and control technologies that reduce thickness irregularities, and technologies for uniformly winding smooth, non-slip films.

As for further pursuing the ultimate in PET film functionality and quality, we are working to achieve defect-free film ahead of our competitors, examining dust-free processes and developing ultra-clean raw materials free of all foreign substances.

Sales & Marketing

Sales & Marketing

Koichi Tonegawa General Manager, Advanced Process Material Department

Toray’s Sales and Marketing Department not only serves as the point of contact for customer requests for delivery, quality, technical development, but is also closely involved in exchanging information with component-related manufacturers and customer sales departments.

Our sales and marketing team also aims to contribute to the innovation of customer products in terms of materials by exploring medium- to long-term market and product development trends from a variety of angles.

Toray’s films business excels in process control in addition to technological capabilities that include surface smoothness and quality improvement. In order to demonstrate such strengths, the Sales and Marketing Department actively listens to customers, playing an important role in establishing a loop connecting customers with Toray’s production, technology, and R&D departments to align Toray with the development direction of customers. Toray sales and marketing staff are truly in the business of creating a value chain story together with customers. However, customer requests are often hinted at through casual day-to-day conversations, often leading to new developments and quality improvements.

Contributing to customers in this way is another hidden strength of Toray’s sales and marketing capabilities.

Production

Production

Teruhisa Kawata General Manager, Second Production Technical Department

Toray Group operates globally, producing PET films at six bases worldwide.

Against this backdrop, we have set up production systems in Japan, the Republic of Korea, and Malaysia for applications related to MLCC, for which demand remains brisk, and each company is pursuing the timely expansion of production capacity to ensure a stable supply to the supply chain.

In order to meet the ever-increasing quality requirements for films used in the production process, Toray production, sales, and engineering teams have worked together to improve the tangible and intangible aspects of the process, helping to improve yields in customer processes. Consequently, the world’s smallest MLCC currently uses exclusively Toray films.

Furthermore, Toray aims to realize quality worldwide.

To this end, we have introduced advanced technologies such as digital transformation (DX) into our production systems and are pursuing enhanced quality and process stability, deploying these technologies from the mother factories in Japan to each of our facilities. We will continue to pursue the highest level of quality and contribute to the market while valuing dialogue with our customers.

Recycling

Recycling

Tsuyoshi Hanamura General Manager, Sustainable Film Business Planning Department

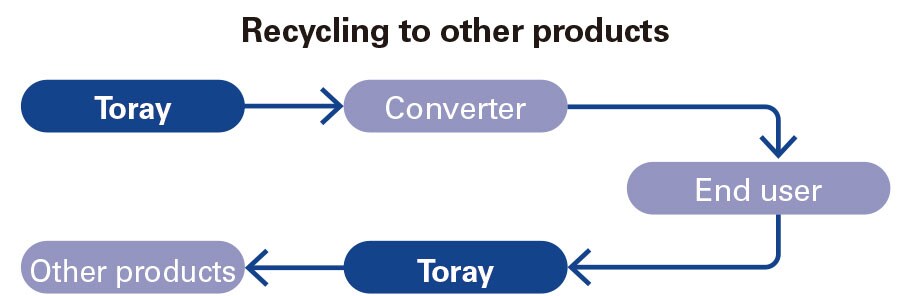

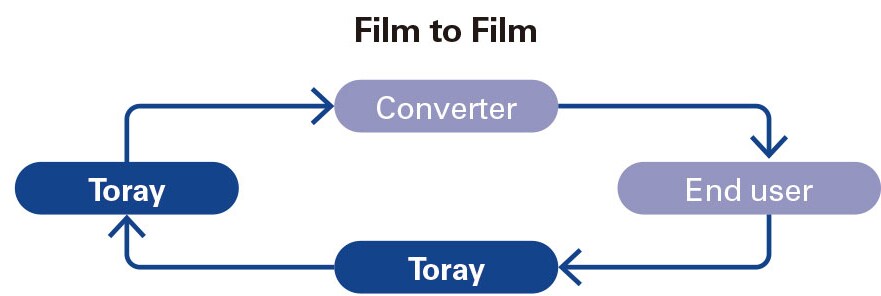

The recycling of films used for MLCC production process has been in the works for 10 years. However, the high level of quality required of the film has prevented us from launching concrete initiatives for quite a while, despite feeling the need to pursue this with our customers. Nevertheless, Toray has built up a track record of recycling and using products that are difficult to recover after use. As a result, we have realized recycling through co-creation initiatives in customer manufacturing activities amid a growing social demand for a circular economy in recent years.

Toray has been recognized by customers for its significant contributions to the establishment of a recycling system in which used PET film is collected during MLCC manufacturing processes and reused as PET film for the same application.